Damping type car gear shifting variable-speed control mechanism

A control mechanism and damping technology, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve problems such as poor control smoothness, structural failure, and reduced reliability, and achieve flexible and convenient operation. The effect of strong bit clarity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

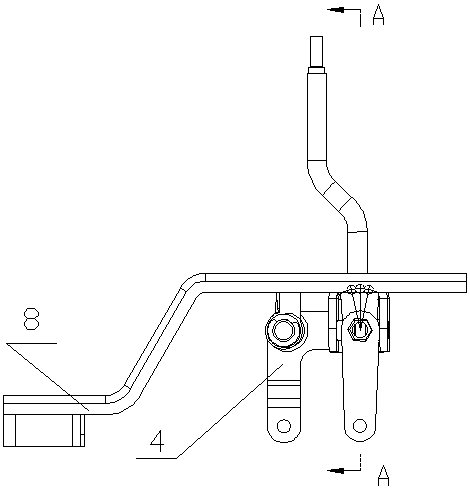

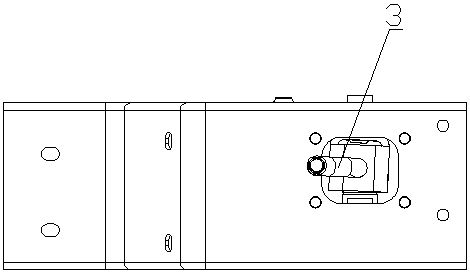

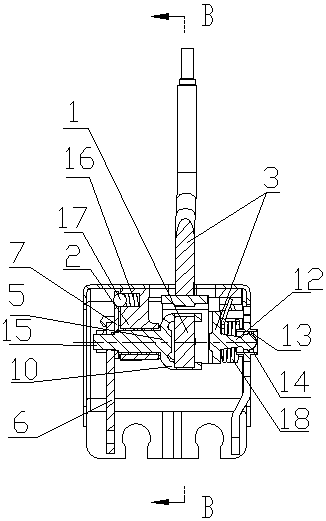

[0013] combined with Figure 1-Figure 5 Further describe the present invention (applicable to realize gear selection and shifting outside the cab), including universal joint cross bearing 1, fixed base 2, joystick assembly 3, gear selection swing arm assembly 4, gear shift shaft assembly 5, The shift arm 6, the damping block 7, and the flexible shaft fixing bracket 8 are characterized in that: the universal joint cross bearing 1 is connected with the U-shaped connecting block 9 of the joystick assembly 3 and the U-shaped connecting block of the shift shaft assembly 5 respectively 10 is fixedly connected; the gear selection swing arm assembly 4 is slidingly connected to the lateral connection hole of the fixed base 2 through the gear selection swing arm shaft 11; , a cylindrical ball bowl 13 is arranged outside the ball head of the ball head swing rod 12, the cylindrical ball bowl and the ball head are slidingly connected, and the cylindrical surface of the cylindrical ball bow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com