Technical method for staining ignition bridgehead of electronic detonator with explosive

A technology of electronic detonator and process method, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of poor firing reliability, accidents, and increased cost of electronic detonator delay modules, etc., to achieve cost reduction and reliable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

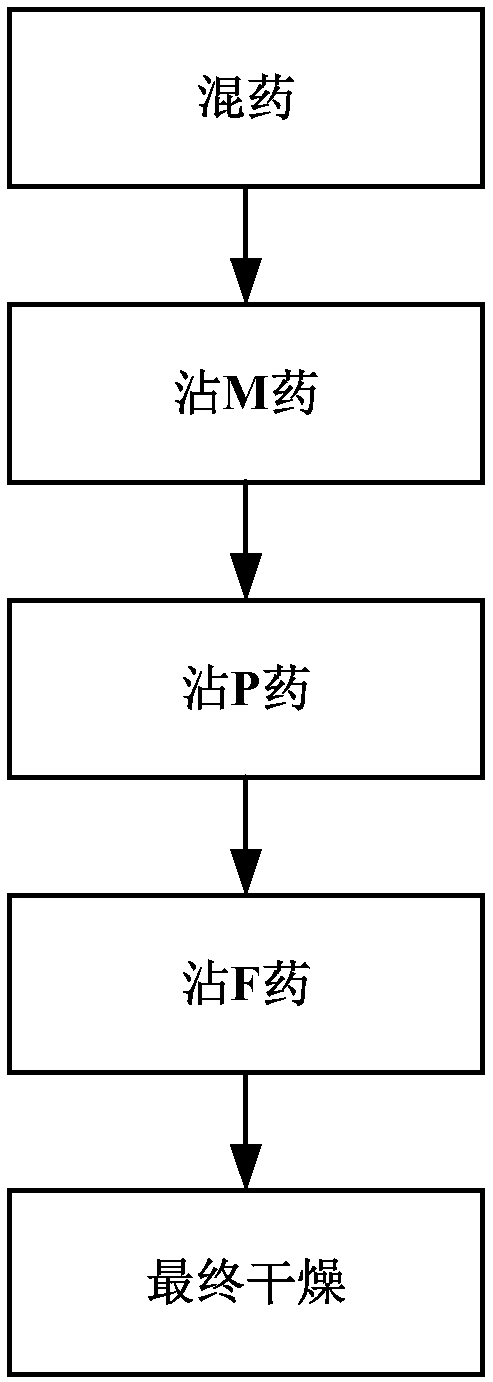

Image

Examples

specific Embodiment 1

[0029] Specific embodiment 1: (1) mixed medicine: make medicine head raw material, described medicine head raw material comprises M medicine, P medicine and F medicine, and described P medicine is the gas production class medicine, comprises potassium picrate and red lead; The F medicine is a moisture-proof medicine; the M medicine is a medicine with a higher sensitivity than the P medicine and the F medicine, and the main component is DDNP;

[0030] (2) Dip M drug: Manually insert the bridge wire of the bridge head into the M drug whose main component is DDNP after dipping it once, turn it 180°, and then dip it again with DDNP M drug, and then put it into the infrared drying equipment for drying, after drying, cycle the above steps again, and alternately carry out twice, that is, complete the process of dipping M drug;

[0031] (3) Dip P medicine: Manually insert the bridge wire of the burning bridge head that has been dried in step (2) into the P medicine made of mixed medic...

specific Embodiment 2

[0034] Specific embodiment 2: (1) mixed medicine: make medicine head raw material, described medicine head raw material comprises M medicine, P medicine and F medicine, and described P medicine is the gas production class medicine, comprises potassium picrate and red lead; The F medicine is a moisture-proof medicine; the M medicine is a medicine with a higher sensitivity than the P medicine and the F medicine, and the main component is DDNP;

[0035] (2) Dip M medicine: first clamp the connecting plate part of the fire bridge head in the fire bridge head medicine dipping plate, then fix the fire bridge head medicine dipping plate on the medicine dipping device, and the bridge wire of the fire bridge head on the medicine dipping device faces Next, dip into the M drug whose main component is DDNP after dipping once, automatically turn the drug dipping device 180°, then dip the M drug whose main component is DDNP again, and then pass it through the tunnel furnace The crawler is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com