Point-to-point multifunctional compound embossing system for paper for daily use

A kind of household paper, point-to-point technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of increasing the production cost of enterprises, switching, unfavorable environmental protection, etc., and achieve the effect of strong combination, good hand feeling and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

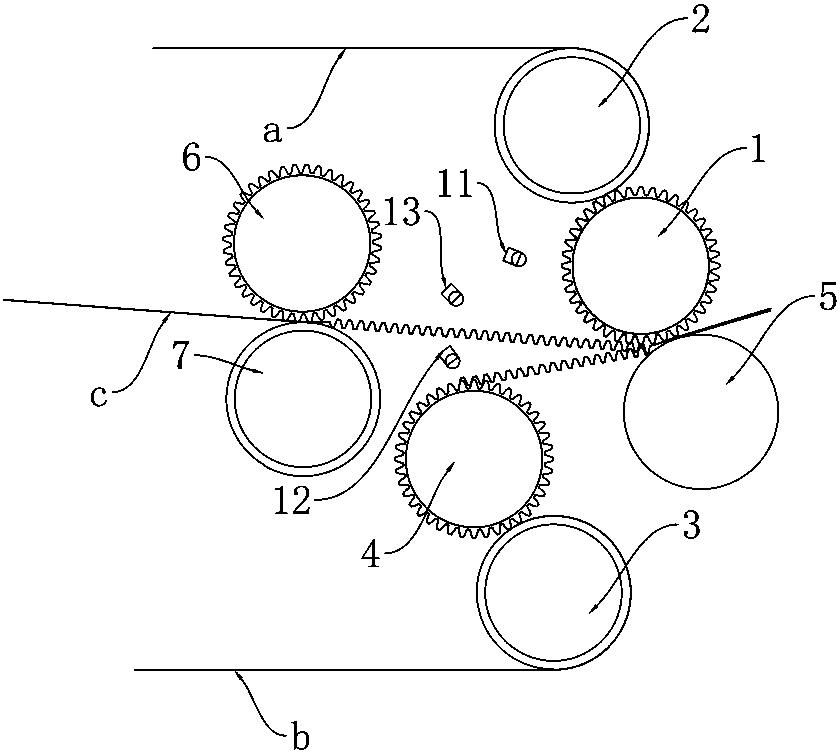

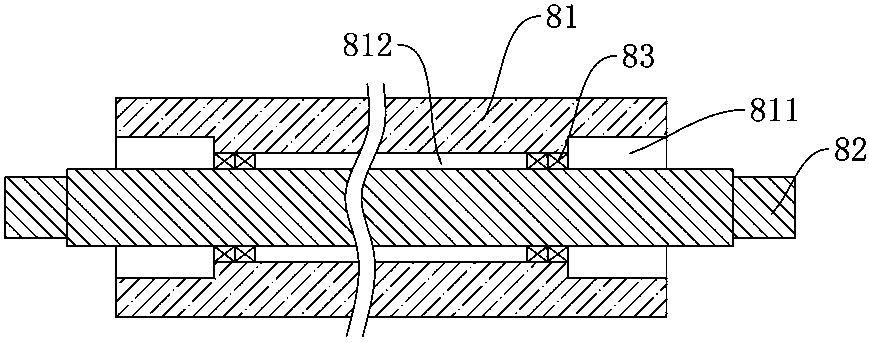

[0026] See attached figure 1 to attach image 3 As shown, in this embodiment, a point-to-point multifunctional composite embossing system for household paper includes an upper rubber roller 2, an upper embossing roller 1, a lower rubber roller 3, a lower embossing roller 4, a smooth roller 5, The rear rubber roller 7 and the rear embossing roller 6, wherein, the upper rubber roller 2 and the smooth roller 5 are respectively close to the upper embossing roller 1, the lower rubber roller 3 and the lower embossing roller 4 are located at the feeding side of the smooth roller 5 and the glue is lowered Roll 3 is interposed between lower embossing roll 4 and smooth roll 5 .

[0027] In this embodiment, the upper rubber roller 2 and the embossing roller are close to each other to cooperate with the embossing, that is, the surface of the upper embossing roller 1 is formed with a raised texture pattern, so that the preset first base paper a The upper rubber roller 2 passes through th...

Embodiment 2

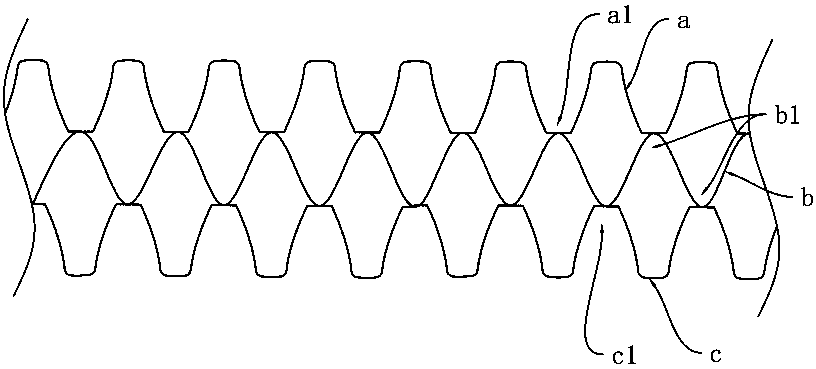

[0041] See attached Figure 4 to attach Figure 6 As shown, in this embodiment, compared with Embodiment 1, in this embodiment, the embossing system can be switched to the way of double-layer base paper compounding at will, and the lower embossing roller 4 and the lower rubber roller 3 or the rear embossing roller 4 can be selected. Any set of the embossing roller 6 and the back rubber roller 7, so that the second base paper b and the first base paper a, or the second base paper b and the first base paper a meet at the tangent point between the upper embossing roller 1 and the smooth roller 5 Cooperate and press together, so that the second recessed point b1 is aligned with the first recessed point a1, or the third recessed point c1 is aligned with the second recessed point b1. In this way, the double-sided composite texture patterns can be switched at will, and different functions can be switched according to the texture patterns of the lower embossing roller 4 and the rear ...

Embodiment 3

[0043] See attached Figure 7 And attached Figure 8 As shown, in this embodiment, compared with Embodiment 1, in this embodiment, the embossing system can be switched to the single-sided embossing double-layer composite method, and the lower embossing roller 4 and the lower rubber roller 3 are selected , so that the second base paper b wraps around the surface of the lower rubber roller 3 and directly meets the first base paper a embossed by the upper rubber roller 2 and the upper embossing roller 1 at the point of tangency between the upper embossing roller 1 and the smooth roller 5. Cooperate with pressing and compounding to realize the production and preparation of single-sided embossed and double-layer composite products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com