Fabric transferring device of sewing machine

A technology for transfer devices and sewing machines, which is applied to sewing machine components, sewing equipment, and cloth feeding mechanisms, and can solve problems such as high cost, increased economic burden, and inability to use sewing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described based on the drawings.

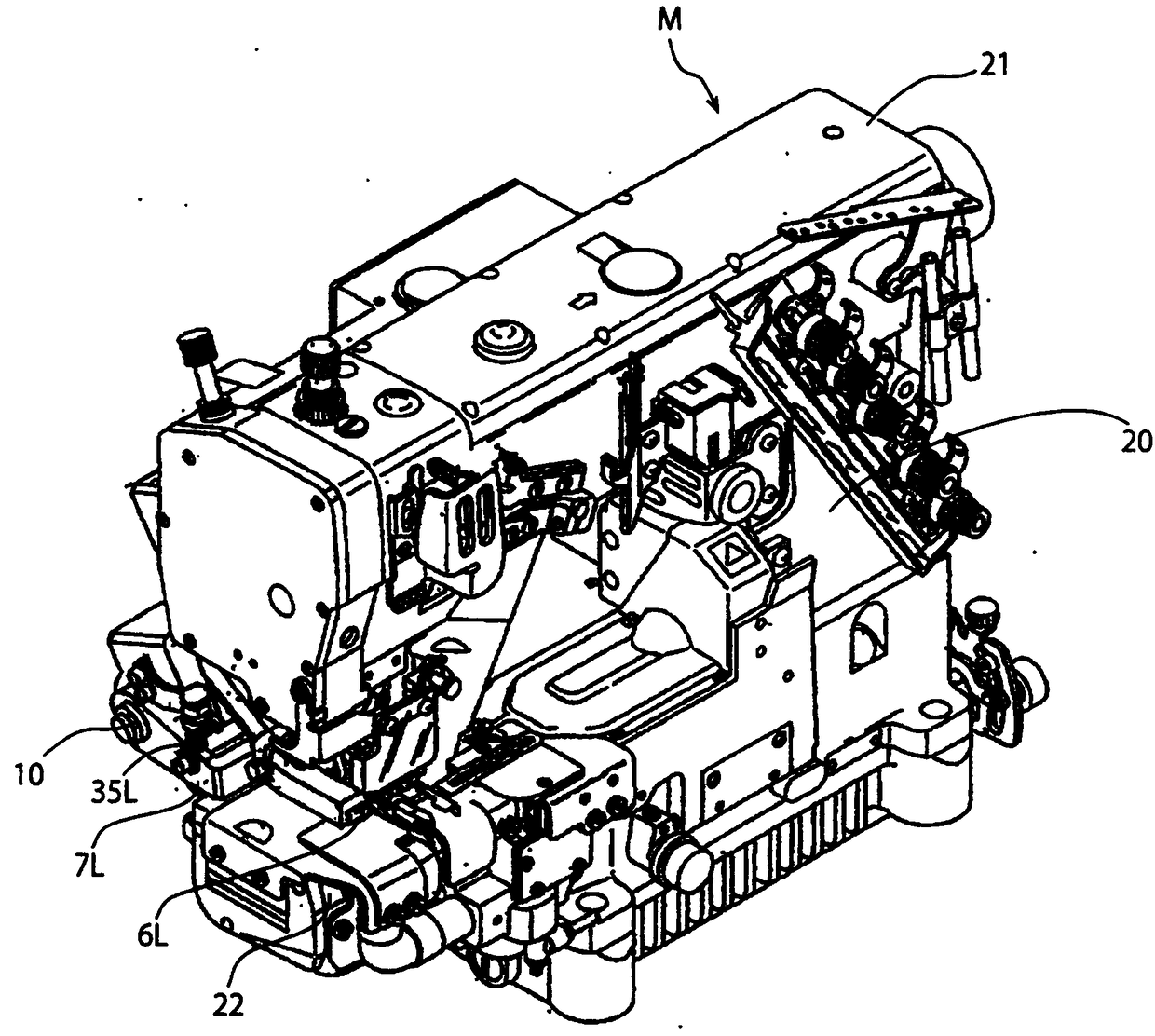

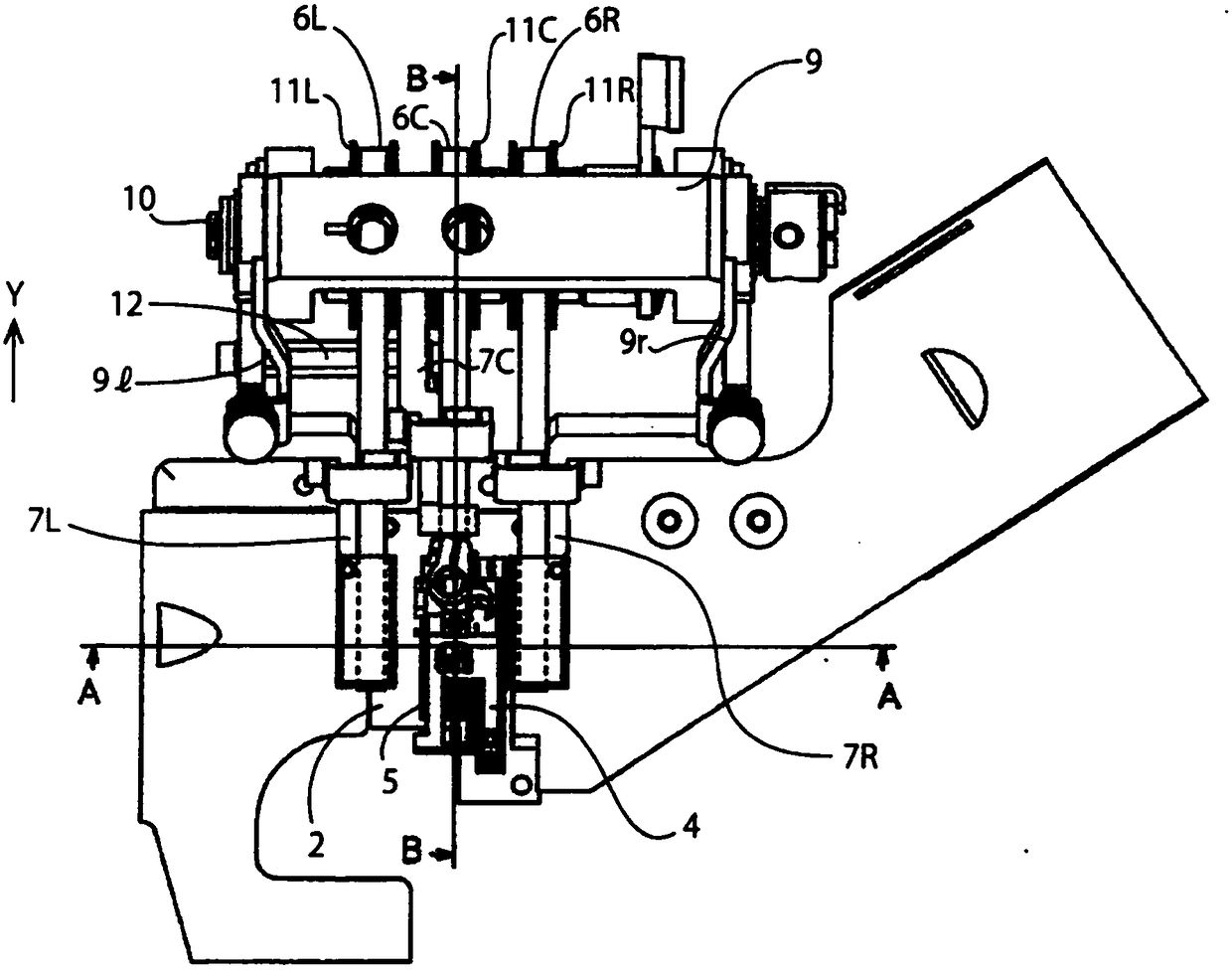

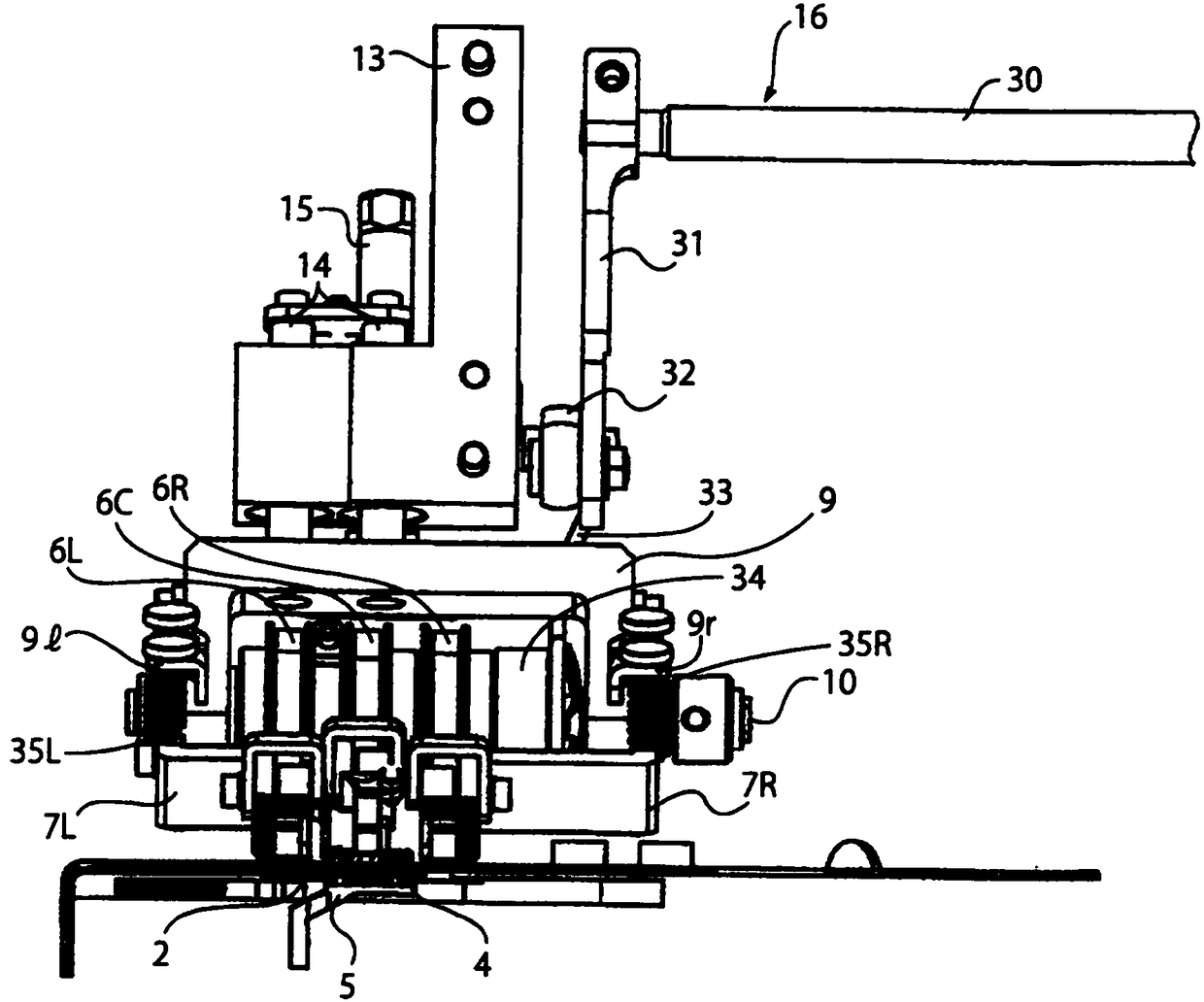

[0055] figure 1 It is a perspective view of the whole of a double-needle horizontal cylindrical double-thread overlock sewing machine according to an embodiment of the present invention, figure 2 It is an enlarged plan view of the main part of the double-needle horizontal cylindrical double-thread overlock sewing machine, image 3 and Figure 4 is along figure 2 Longitudinal sectional view of A-A line and B-B line.

[0056] In the above-mentioned double-needle horizontal cylindrical double-thread lockstitch sewing machine M, the sewing machine arm 21 and the sewing machine base 22 extend substantially parallel to each other from the upper and lower parts of the sewing machine body 20 toward the left. Inside the arm portion 21 of the sewing machine, the main shaft of the sewing machine and the left and right needles 1, 1 arranged side by side in a direction substantially pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com