Large-diameter pipe pile centrifugal test model making equipment and its working method

A technology of centrifugal test and large-diameter tube, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of high cost, manual completion, and geometric error of centrifugal model, so as to eliminate the elevation error of model making, avoid Excessive perturbation, avoiding the effect of insufficient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1, test and approach , pic 1 to pic 14-1、 pic 14-2, test 、、,1615,2014,11 to ;14,871,721,1 and ;4121,1310;、18 and 19 to 。、10,11, to ,, and test preparation 。 specific Embodiment approach

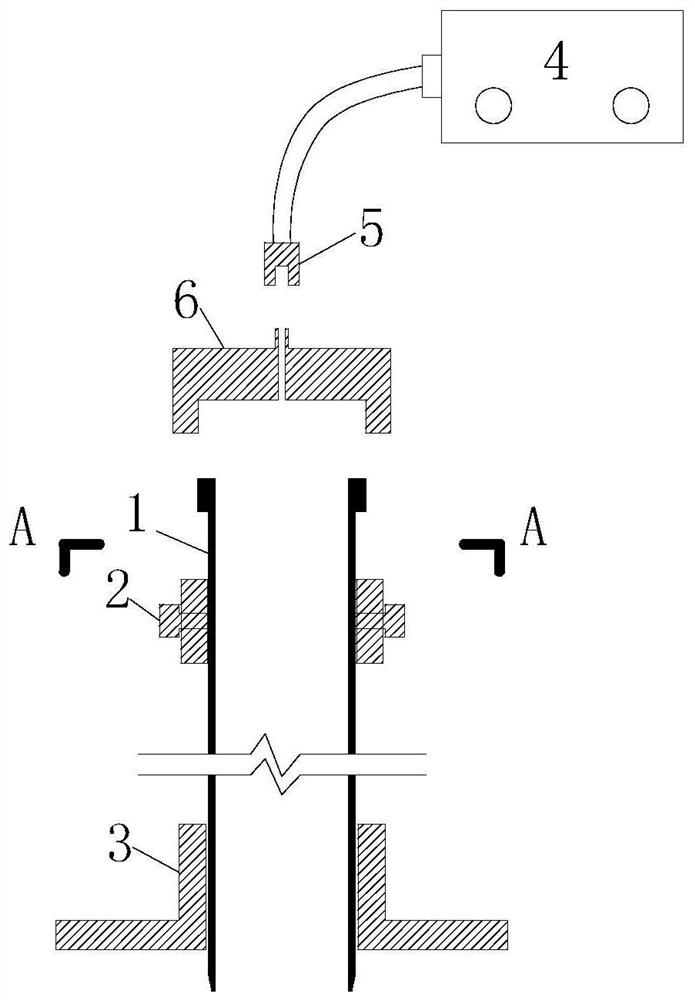

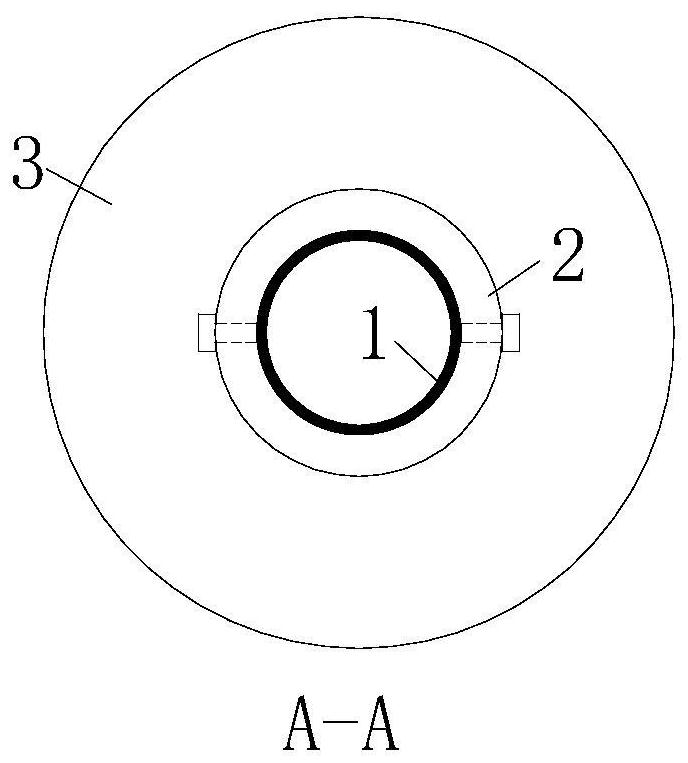

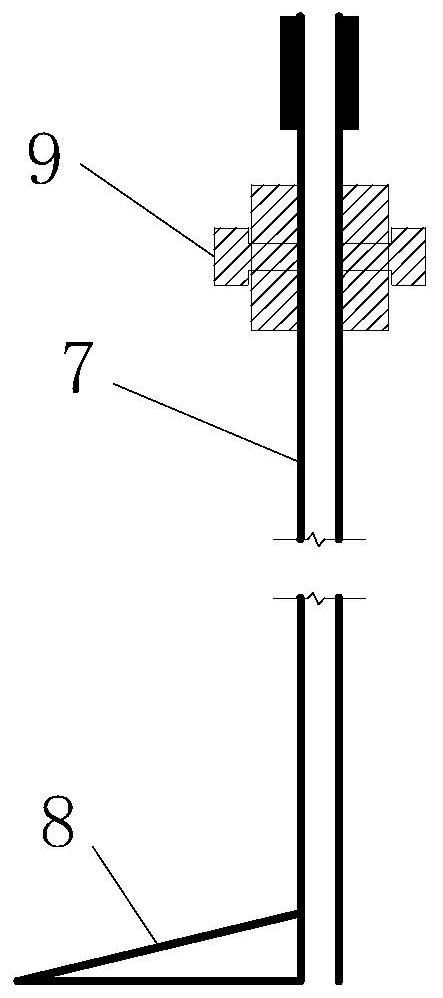

[0052] Embodiment 1, large-diameter pipe pile centrifugal test model making equipment and working method thereof, such as Figure 1 to Figure 14-1 , Figure 14-2 Shown, the large-diameter pipe pile centrifugal test model making equipment of the present invention mainly comprises cutting and scraping device, guide hole earth taking device, pile backfilling device, uses the scraping footage 15 that has soil cutting steel wire 16 at the bottom, and in Evenly move the scraping beam 14 on the model box 20, and cut the model soil sample 11 to the design depth; after the thin-walled guide hole soil pipe 1 is connected to the vacuum pump 4, it can sink autonomously under the action of vacuum suction, and the suction sinking method is also used. The air thin tube 7 with the arc-shaped shavings 8 at the bottom is close to the inner wall of the thin-walled soil-taking pipe 1 and inserted into the soil, the subsoil is cut off by turning and pulling out the air thin pipe 7 to form the air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com