Delayed coking tower and method for preparing needle coke

A technology of delayed coking and needle coke, which is applied in the direction of coking carbonaceous materials, coking ovens, only multi-stage series refining and cracking process, and can solve the problems of coking in heating furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

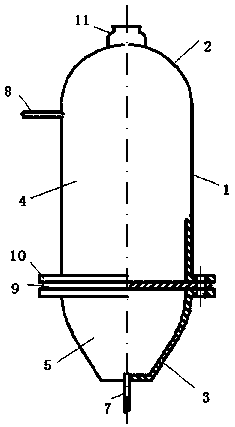

[0035]EXAMPLES The delayed coking tower and the method for preparing needle coke according to the present invention are used, the raw material oil and circulating oil are fed from the top, and the substances that are not easy to coke are fed from the bottom to carry out the delayed coking reaction. The height from the upper feed inlet to the bottom of the tower is 4 / 5 of the total tower height, and the height of the packing section at the bottom of the tower is 1 / 10 of the total tower height.

[0036] The raw oil mixed with part of the circulating oil is heated by the raw oil heating furnace and then enters the delayed coking tower with a circulation ratio of 0.8. The raw material oil heating furnace adopts variable temperature control, the initial temperature is 470°C and is maintained for 15 hours, and then the temperature is raised to 510°C at a rate of 4°C / h and maintained for 3 hours; when the outlet temperature of the raw material oil heating furnace reaches 490°C, the lo...

Embodiment 2

[0038] It is the same as in Example 1, except that the raw material oil mixed with part of the circulating oil enters the delayed coking tower after being heated by the raw material oil heating furnace, and the circulation ratio is 1.3. The raw oil heating furnace adopts variable temperature control, the initial temperature is 470°C and is maintained for 15 hours, and then the temperature is raised to 510°C at a rate of 4°C / h and maintained for 3 hours; when the outlet temperature of the raw oil heating furnace reaches 490°C, it is not easy to feed from the bottom of the delayed coking tower The coking substances and the non-coking substances are pre-heated by a heating furnace controlled by variable temperature, the initial temperature is 485°C, and then the temperature is raised to 520°C at a uniform speed within 3 hours, and the temperature is kept constant until the raw oil pump is stopped. Wherein, the feeding amount of the non-coking material is the same as that of the up...

Embodiment 3

[0040] It is the same as in Example 1, except that the raw material oil mixed with part of the circulating oil is heated by the raw material oil heating furnace and then enters the delayed coking tower, and the circulation ratio is 1.5. The raw material oil heating furnace adopts variable temperature control, the initial temperature is 485°C and is maintained for 17 hours, and then the temperature is raised to 515°C at a rate of 3.5°C / h and maintained for 2 hours; when the outlet temperature of the raw material oil heating furnace reaches 490°C, it is not easy to feed from the bottom of the delayed coking tower The coking material and the material that is not easy to coke are heated in a heating furnace controlled by variable temperature in advance, the initial temperature is 495°C, and then the temperature is raised to 530°C at a uniform speed within 3 hours, and the temperature is kept constant until the raw oil pump is stopped. Among them, the feed amount of the non-coking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com