Pressure refueling pipeline outlet flow control device

A flow control and refueling pipeline technology, applied in the direction of liquid conveying devices, can solve the problems of turbulent flow and separated flow, causing danger, electrostatic discharge, etc., to increase the cross-sectional area of the outlet flow, ensure the safety of refueling, and avoid excessive disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the outlet flow control device of the pressure refueling pipeline of the present invention will now be described with reference to the accompanying drawings.

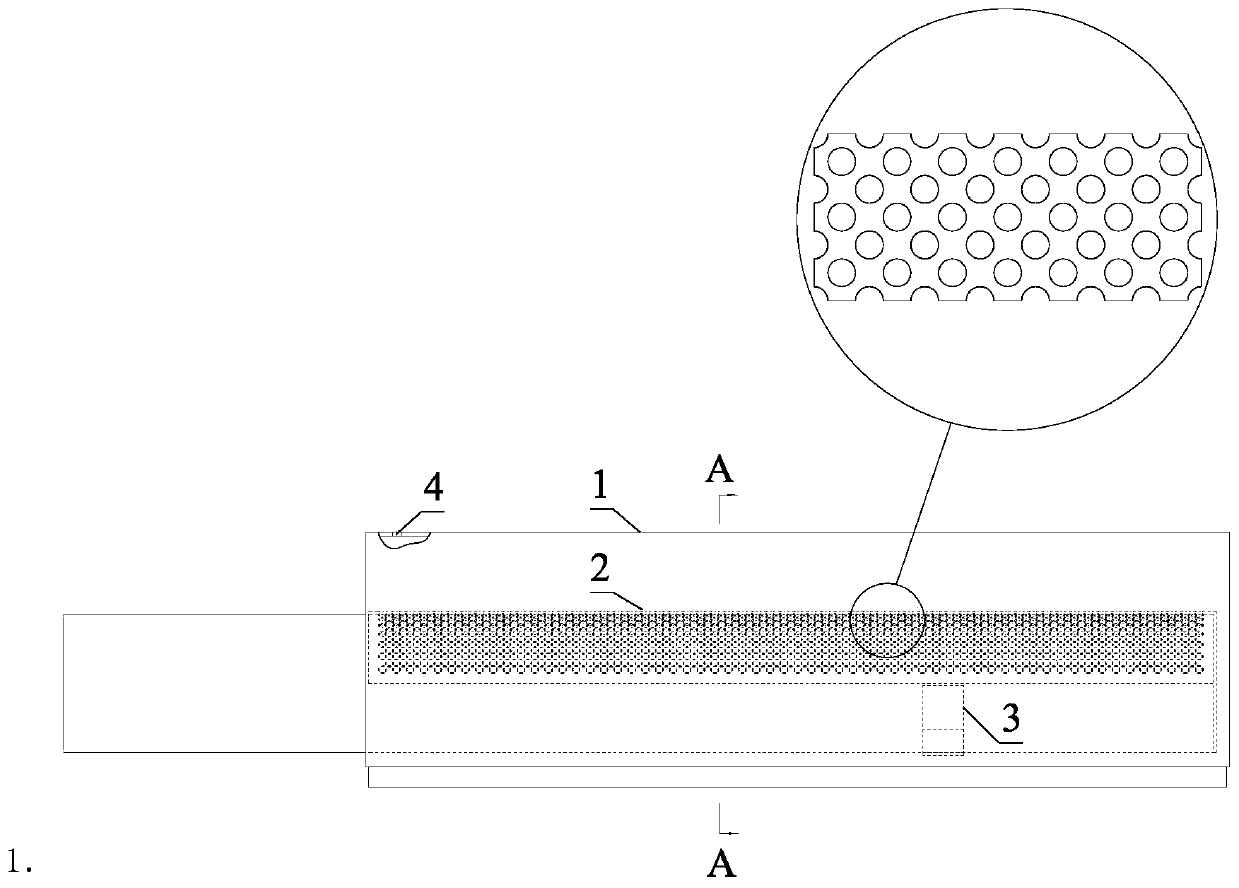

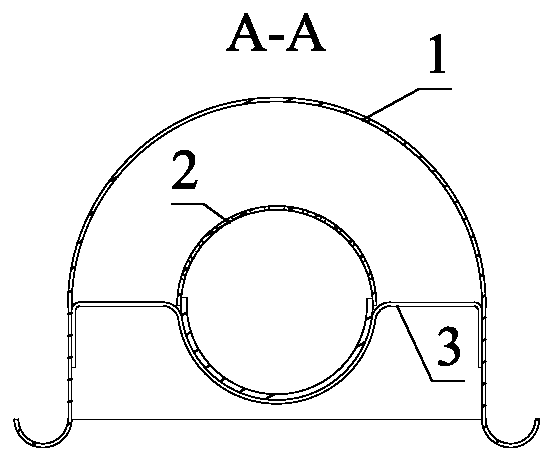

[0016] Such as figure 1 and figure 2 As shown, a pressure fueling pipeline outlet flow control device adopts the structure of porous outlet + baffle guide, which can make the fuel flow evenly and smoothly when the high-speed fuel enters the fuel tank. It is characterized in that when the refueling flow rate of the outlet flow control device of a single pressure refueling pipeline is about 25000L / h, the diameter of the porous pipe 2 is not less than 50mm, the length of the porous part is about 300mm, the diameter of a single through hole is 2mm, and the total small hole flow area is about 0.01m2, to ensure that the average outflow velocity of the fuel oil from the small hole is less than 1m / s, and the determination of the area takes into account the margin.

[0017] Take the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com