Construction method of parallel operation of steel pipe arch construction, laying and erecting

A technology of parallel operation and construction method, which is applied to arch bridges, erection/assembly bridges, bridge materials, etc., to achieve the effects of saving construction period, light weight, and ensuring safety during construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the specific embodiments, which further illustrate the principles of the present invention and do not limit the present invention in any way, and the same or similar technologies as the present invention do not exceed the protection scope of the present invention.

[0026] In conjunction with the attached drawings.

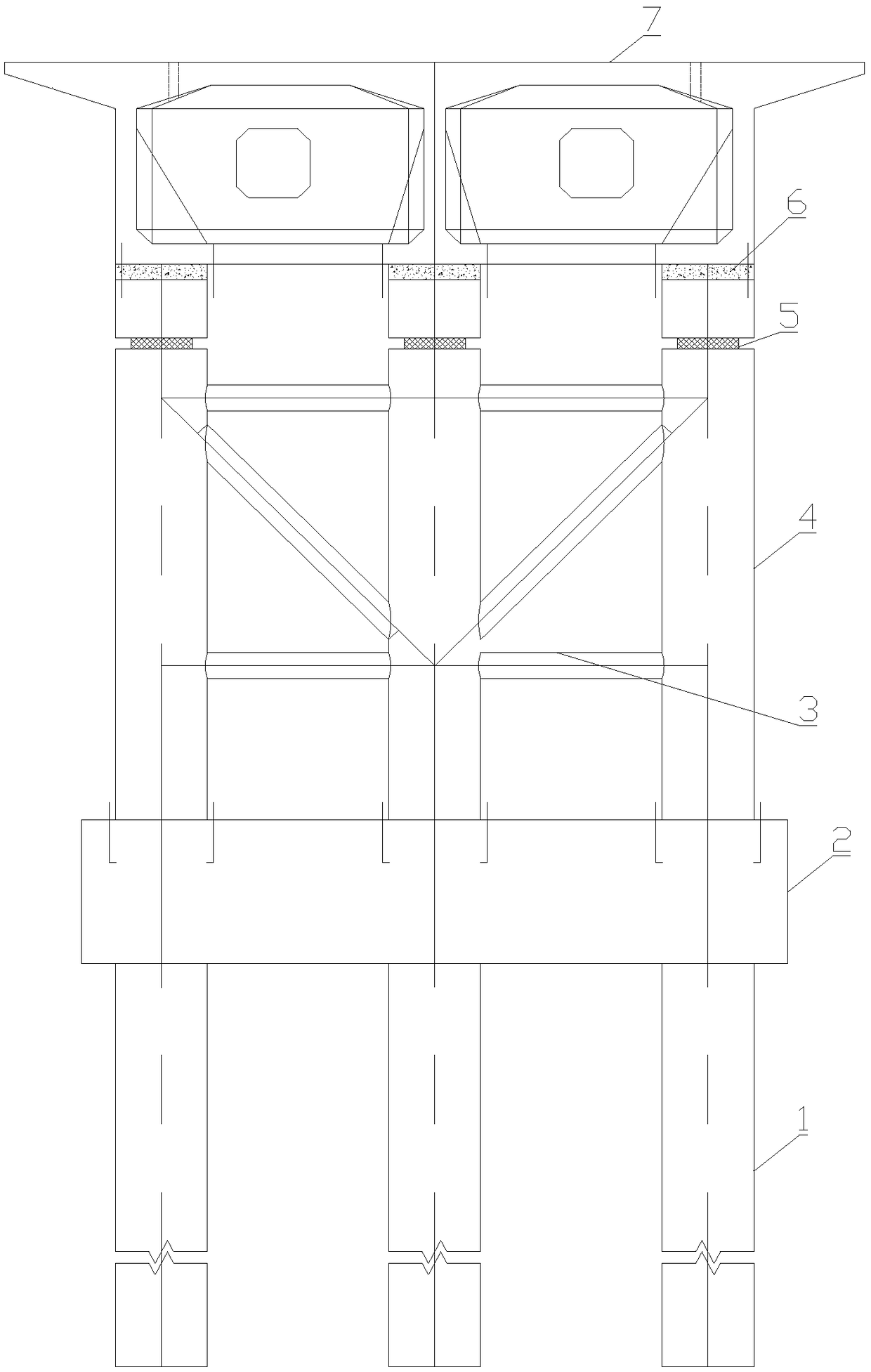

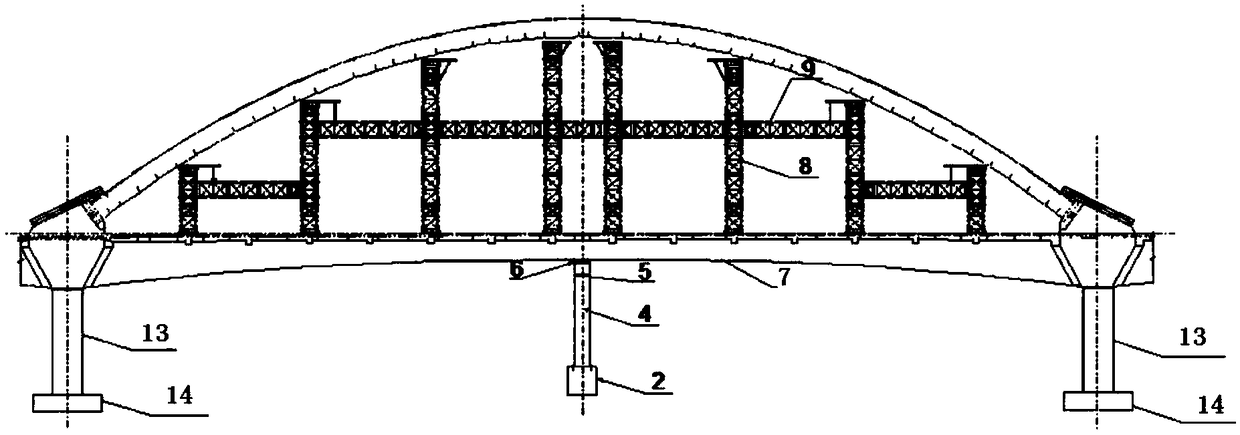

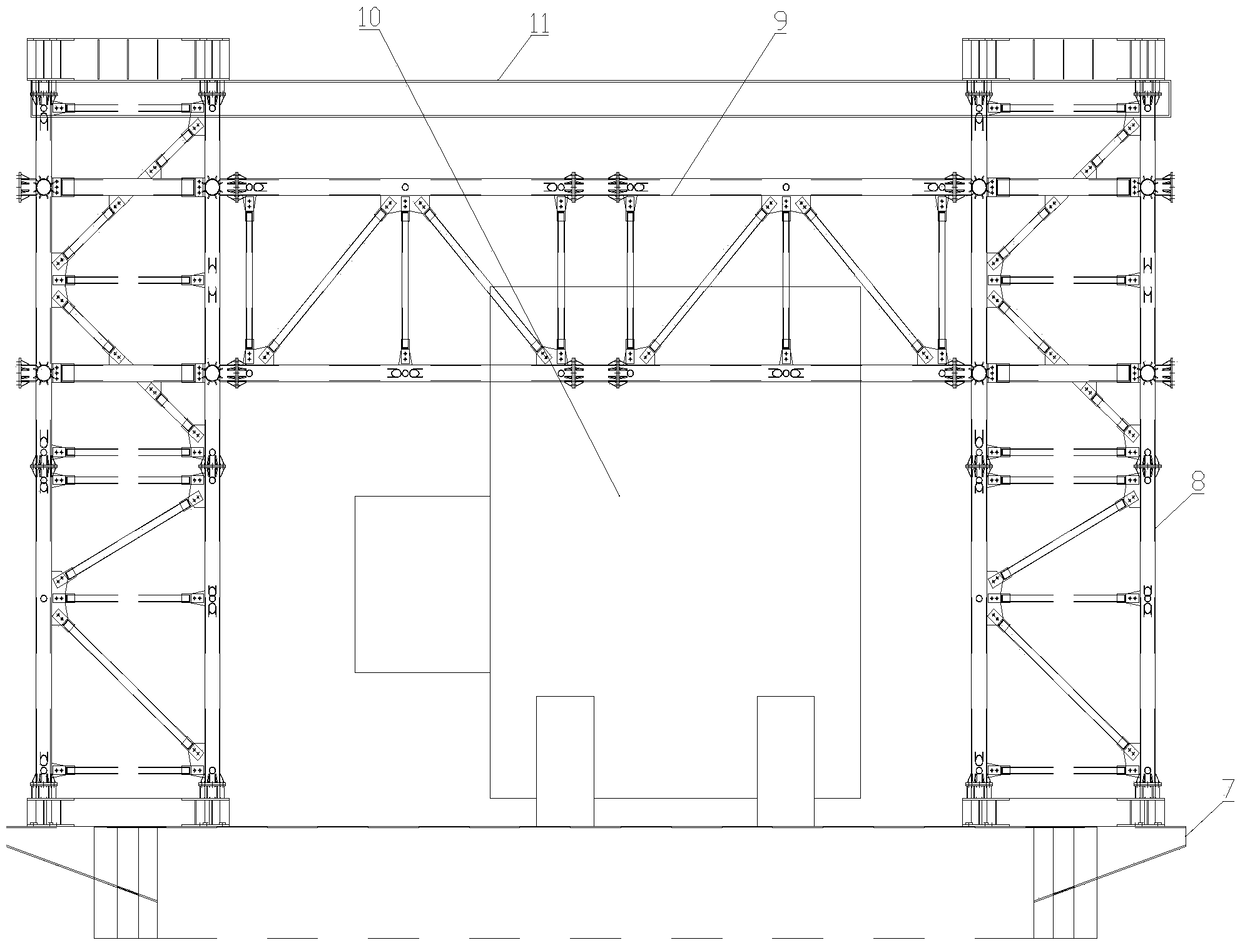

[0027] The construction method of the steel pipe arch construction and the parallel operation of the laying frame includes the following methods: constructing a temporary buttress at the closing part of the main beam, and constructing an independent lattice type support on the main beam;

[0028] The construction of the temporary pier is: when the main beam 7 is constructed to the closed mid-span, the temporary pier is constructed at the closed mid-span, including: constructing the buttress pile foundation 1, after the completion of the buttress pile foundation 1, constructing the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com