A method for preparing needle coke

A needle coke and coking tower technology, which is used in the petroleum industry, processing hydrocarbon oil, etc., can solve problems such as coking in heating furnaces, and achieve the effects of increasing linear speed, good dispersion, and stable development of the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

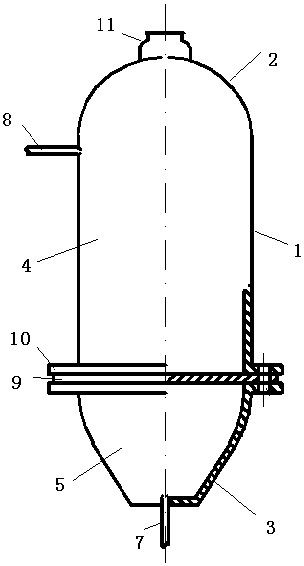

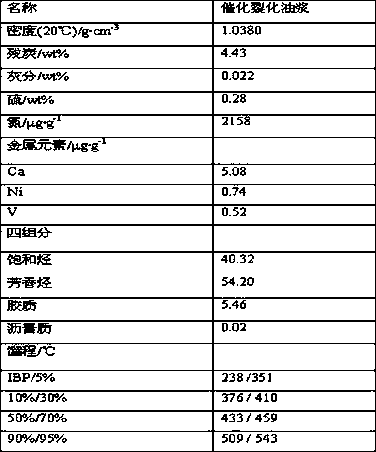

[0037]Using the method for preparing needle coke in the coking tower of the present invention, the raw material oil and the circulating oil adopt the upper and lower feeding methods, and the materials that are not easy to coke adopt the lower feeding method to carry out the delayed coking reaction. The height from the upper feed inlet to the bottom of the tower is 4 / 5 of the total tower height, and the height of the packing section at the bottom of the tower is 1 / 10 of the total tower height.

[0038] The mixed circulating oil of raw material oil enters the coking tower after being heated by the raw oil heating furnace. The circulation ratio is 0.8. 3h. When the outlet temperature of the raw oil heating furnace is at a constant temperature of 470°C, the raw material oil and circulating oil enter the coking tower from the upper feed port; tower; when the raw oil heating furnace reaches 500°C, the substances that are not easy to coke will also enter the coking tower from the lo...

Embodiment 2

[0040] EXAMPLES The method of the present invention is used to prepare needle coke. Different from Example 1, the coking tower has a pressure relief process during the coking process.

[0041] The mixed circulating oil of raw material oil enters the coking tower after being heated by the raw oil heating furnace. The circulation ratio is 1.2. 3h. When the outlet temperature of the raw oil heating furnace is at a constant temperature of 480°C, the raw material oil and circulating oil enter the coking tower from the upper feed port; Coking tower: When the raw oil heating furnace reaches 505°C, the substances that are not easy to coke will also enter the coking tower from the lower feed port after being pre-heated. The heating process of the non-coking material is also controlled by variable temperature. The initial temperature is 505°C, and then the temperature is raised to 530°C at a rate of 10°C / h and kept at a constant temperature until the end of the reaction. The feed amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com