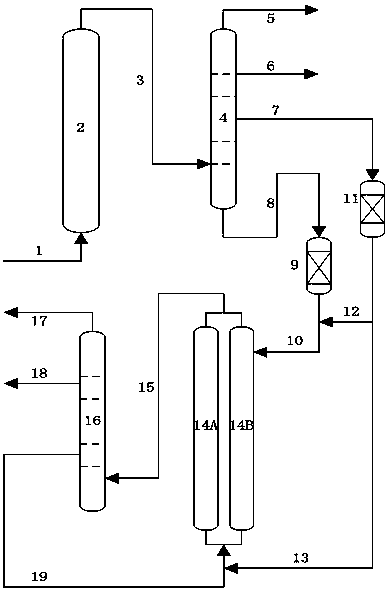

Catalytic cracking-delayed coking combined process for preparing needle coke

A technology of catalytic cracking and delayed coking, which is applied in the field of needle coke preparation by combined process of catalytic cracking and delayed coking, which can solve the problems of not being able to meet the large cycle ratio, achieve the effect of "promoting coke pulling", improve the uniform distribution of system temperature, and disperse Promoted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

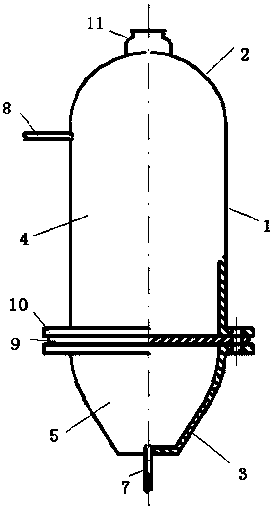

[0035] The coking tower and the combined process method for preparing needle coke according to the present invention are adopted, wherein the height from the upper feed port of the coking tower to the bottom of the tower is 4 / 5 of the total tower height, and the height of the packing section at the bottom of the tower is 1% of the total tower height / 10.

[0036] The basic properties of the catalytic cracking raw oil are shown in Table 1, and the process conditions of the catalytic cracking unit are shown in Table 2. The catalyst is RICC-1. The catalytic cracking products enter the fractionation system to separate out gas, light oil, middle distillate oil and catalytic oil slurry. Among them, the middle distillate oil and catalytic oil slurry are filtered to reduce the ash content to less than 0.1%. In addition, the distillation range of middle distillates is 382°C to 459°C; the cycle oil produced by delayed coking is >355°C fraction.

[0037] Table 1 Basic properties of FCC ...

Embodiment 2

[0043] Example The needle coke was prepared by the method of the present invention, the difference from Example 1 is that the operating conditions of the delayed coker are different.

[0044] The coking heating furnace adopts variable temperature control, the initial temperature is 450°C and maintained for 13h, and then the temperature is raised to 505°C at a rate of 3°C / h and maintained for 2h. When the outlet temperature of the heating furnace is at a constant temperature of 450°C, the middle distillate oil and catalytic oil slurry generated by the catalytic cracking unit enter the coking tower from the upper feed port; The circulating oil generated by the oil and coking unit enters the coking tower from the lower feed port until the end of the constant temperature of 505°C, wherein the feeding amount of the circulating oil is 1 times that of the middle distillate oil. During the whole reaction process, the temperature in the coking tower ranges from 433°C to 497°C, and the ...

Embodiment 3

[0046] Example The needle coke was prepared by the method of the present invention, the difference from Example 1 is that the operating conditions of the delayed coker are different.

[0047] The coking heating furnace adopts variable temperature control, the initial temperature is 440°C and is kept for 16h, and then the temperature is raised to 500°C at a rate of 4°C / h and kept for 2h. When the outlet temperature of the heating furnace is at a constant temperature of 440°C, the middle distillate oil and catalytic oil slurry generated by the catalytic cracking unit enter the coking tower from the upper feed port; The circulating oil generated by the oil and coking unit enters the coking tower from the lower feed port until the end of the constant temperature of 500 ° C, wherein the feeding amount of the circulating oil is 1 times that of the middle distillate oil. During the whole reaction process, the temperature in the coking tower ranges from 433°C to 497°C, and the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com