Slot cooling structure capable of improving cooling efficiency of end wall of fixed blade channel

A cooling structure and cooling efficiency technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as the impossibility of cooling the front edge of the vane and the end wall near the pressure surface side, so as to prevent the intrusion of high-temperature gas and improve cooling Efficiency, safety and effective work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

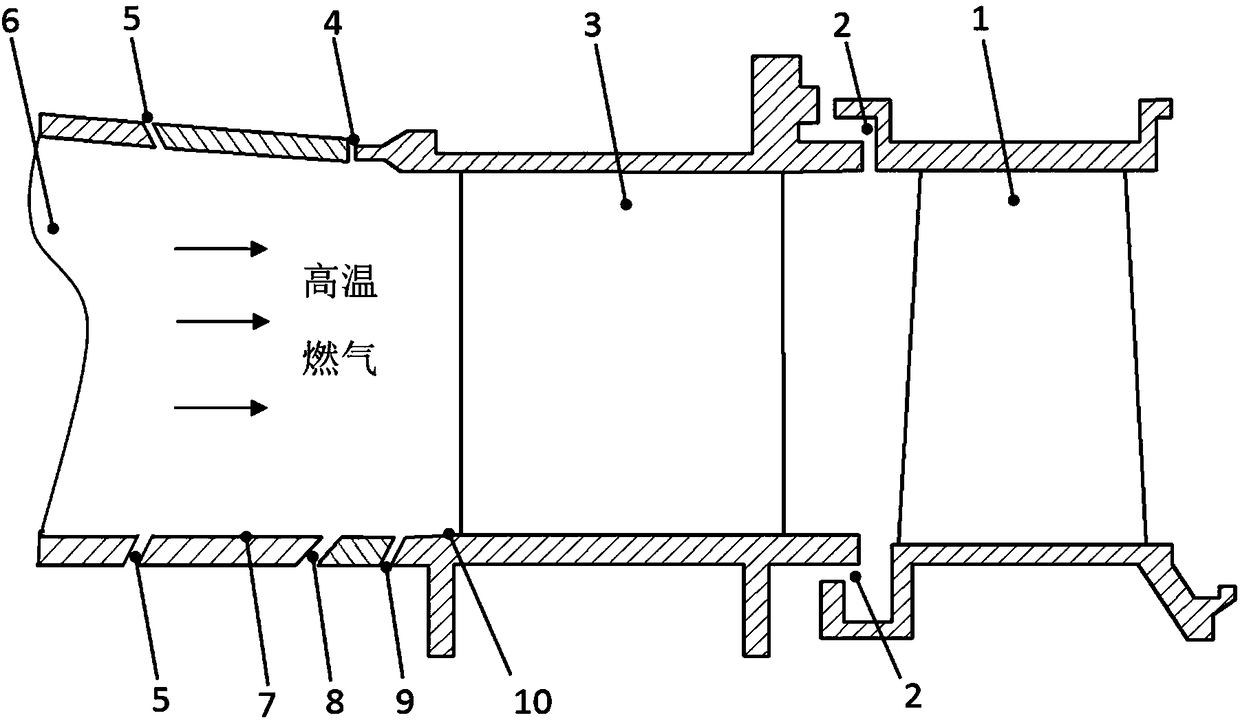

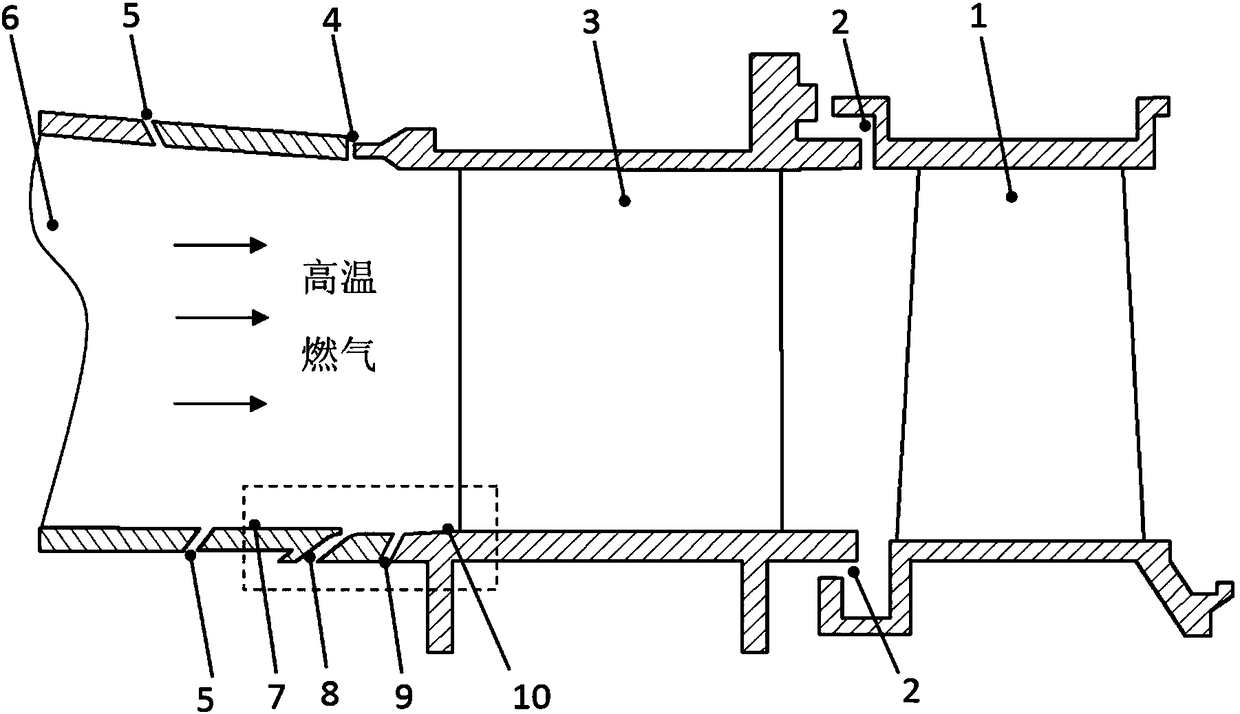

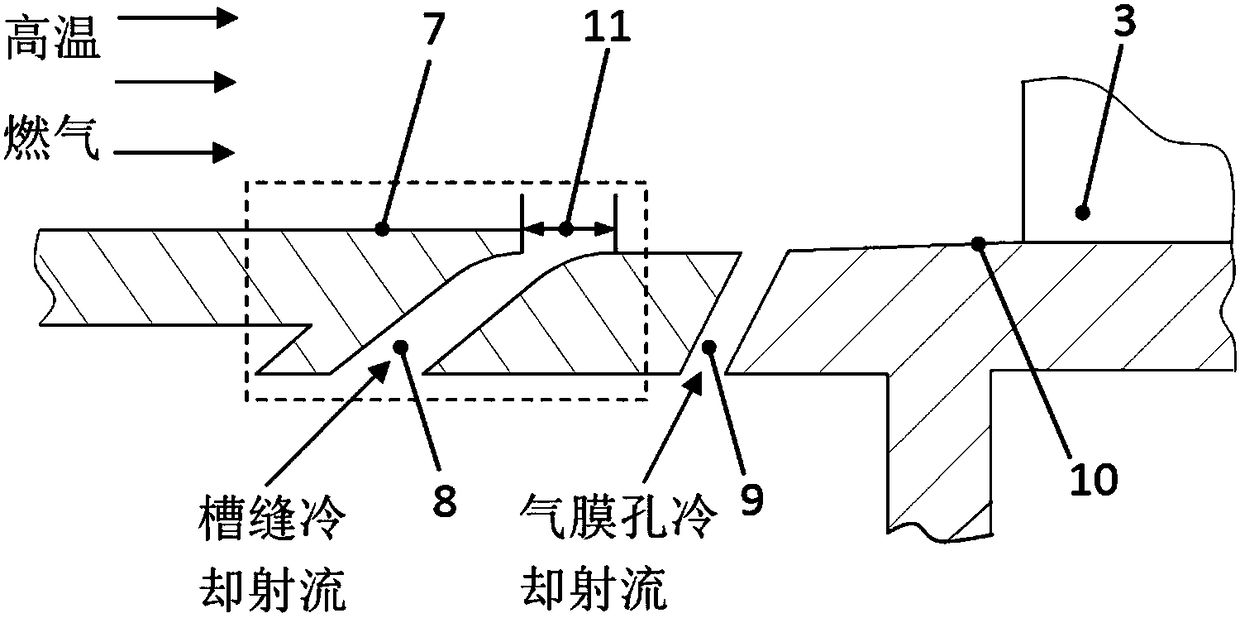

[0029]The present invention will be further described in detail below in conjunction with the accompanying drawings and technical principles. Concrete structure of the present invention sees appendix Figure 2-9 , the design idea is as follows:

[0030] see Figure 2 to Figure 4 ,and figure 1 Compared with the traditional traditional slot cooling structure, the slot cooling structure 8 of the present invention introduces a transition fillet in the contact section between the front surface 12 of the slot cooling structure and the rear surface 13 of the slot cooling structure and the end wall 10 of the vane channel and produces The height difference H 14 between the outlet of the combustion chamber upstream of the slot and the end wall of the vane is the height of the side surface 15 of the sudden expansion step at the outlet of the combustion chamber. Wherein, the determination of the height difference H14 between the outlet of the combustion chamber and the end wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com