Fan blade assembly of cooling fan

A heat dissipation fan and fan blade technology, which is applied to the parts of the pumping device for elastic fluid, pump elements, non-variable pumps, etc., can solve the problem that the center of the fan blade cannot generate wind, the surrounding wind is strong, and the wind is weak, etc. problems, to achieve the effect of increasing softness, avoiding deformation and cracking, and increasing air volume and wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

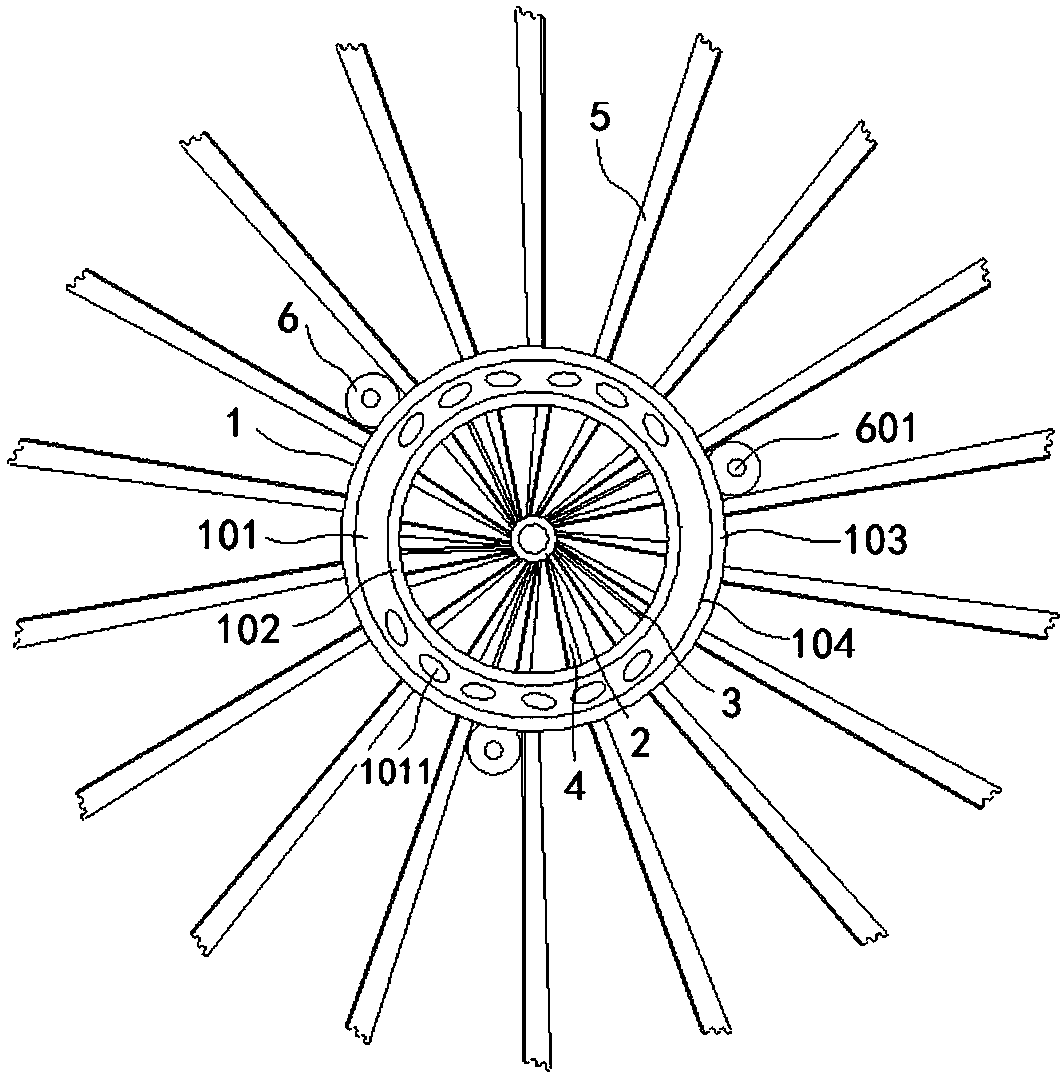

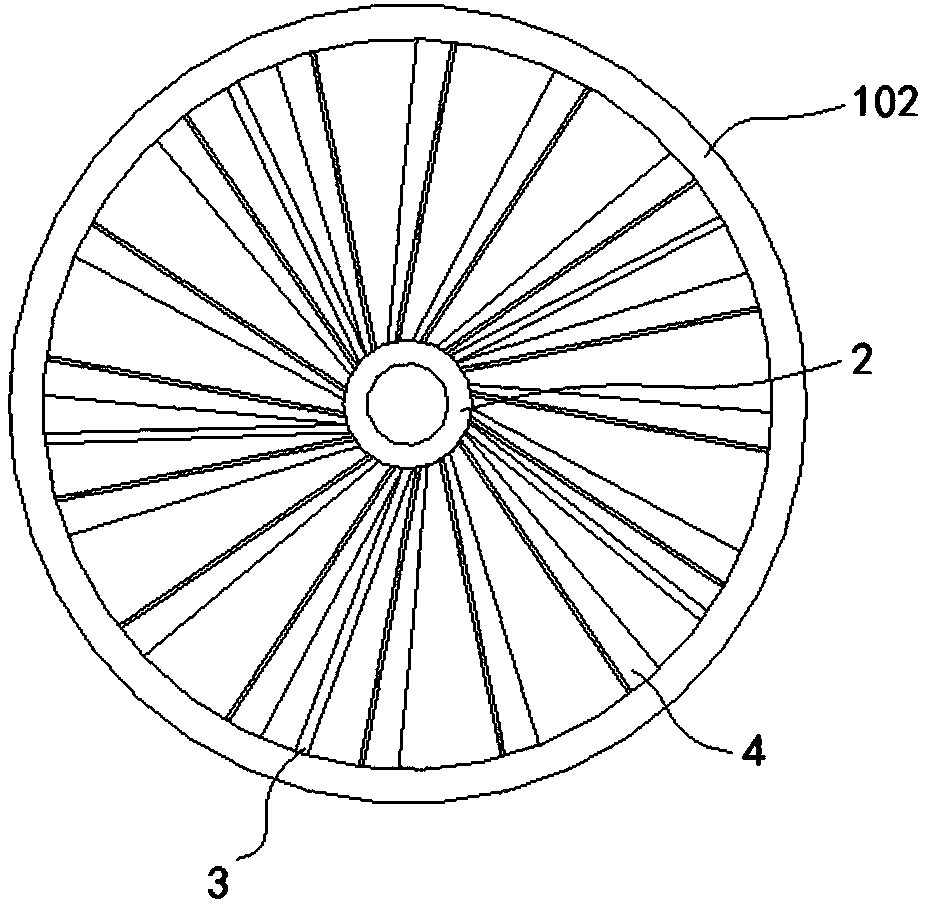

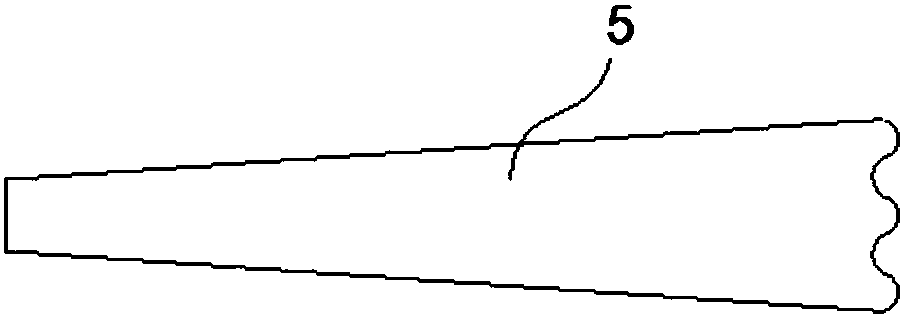

[0022] Such as figure 1 , figure 2 , image 3 As shown, a fan blade assembly of a cooling fan of the present invention includes:

[0023] The hub 1, the hub 1 is connected with an external motor, the hub 1 includes an annular bottom surface 101, the inner side of the bottom surface 101 is formed with an annular first bump 102 perpendicular to the bottom surface 101, the bottom surface 101 The outer side is formed with an annular second bump 103 perpendicular to the bottom surface 101, the outer side wall of the first bump 102 and the inner side wall of the second bump 103 form an annular groove 104, the hub 1 An annular connecting ring 2 is formed at the center of the hub 1 , and several reinforcing ribs 3 are connected between the outer sidewall of the connecting ring 2 and the inner sidewall of the first protrusion 102 on the hub 1 . A plurality of arc-shaped protrusions 6 are formed around the bottom surface 101 of the hub 1 , and mounting holes 601 are formed on the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com