An improved auxiliary transmission

An auxiliary transmission, an improved technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of inconvenient maintenance, gear fatigue wear, inconvenient installation, etc., to ensure installation efficiency and The effect of accuracy of use, easy storage, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

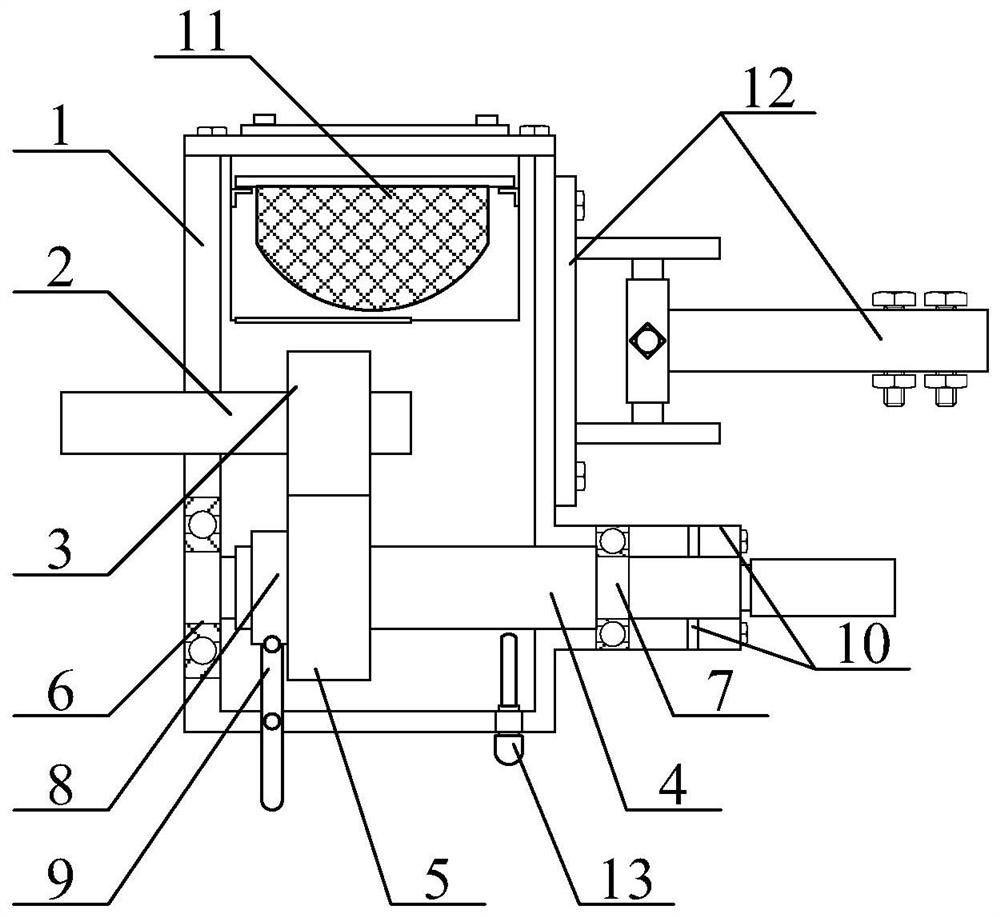

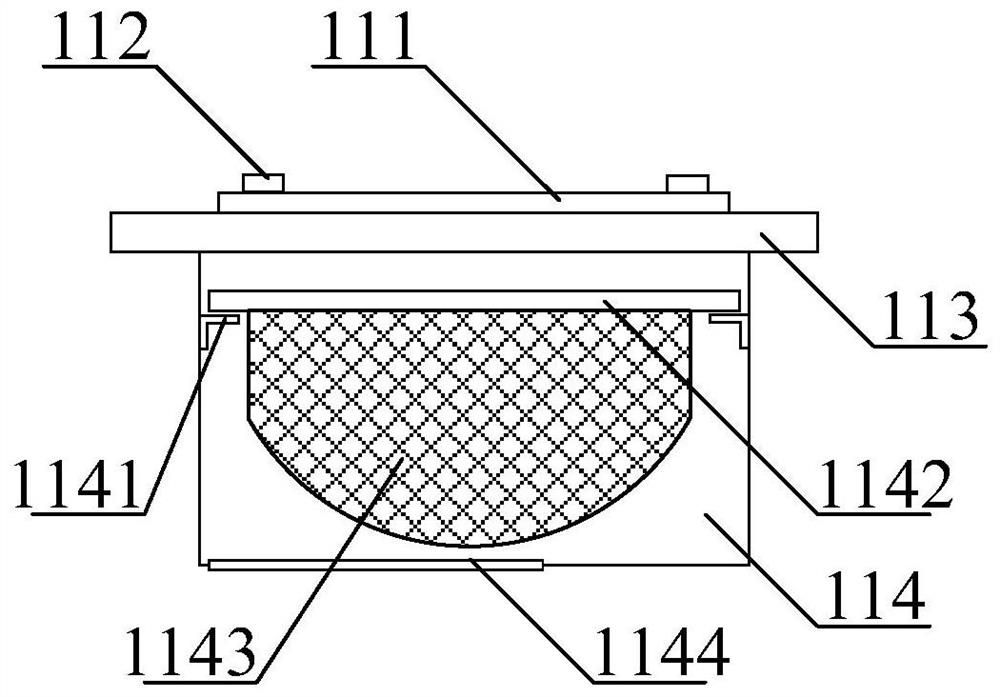

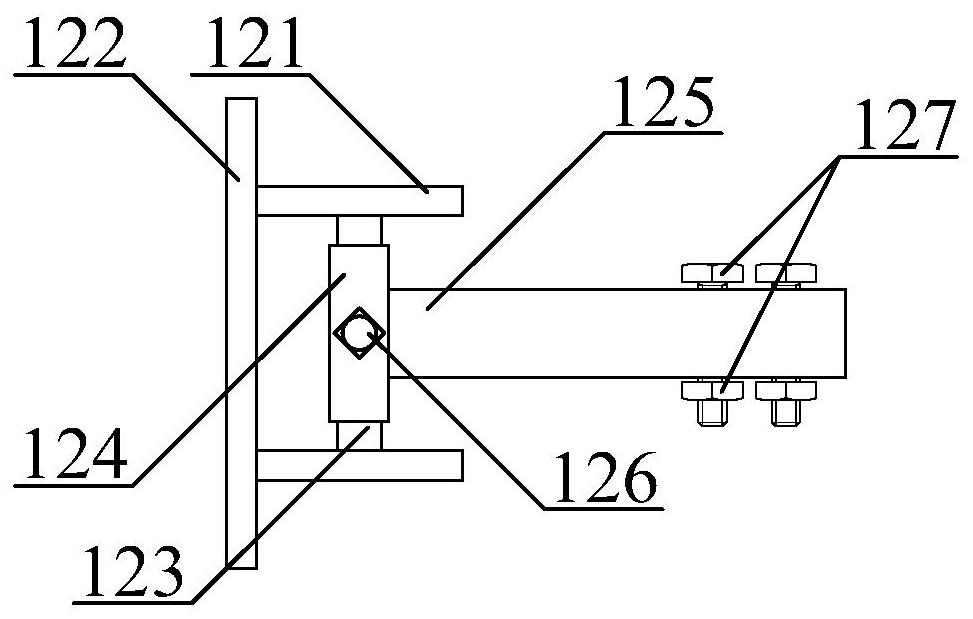

[0032] as attached figure 1 to attach Figure 4 shown

[0033] The present invention provides an improved auxiliary transmission, comprising a transmission case 1, an auxiliary transmission input shaft 2, a duplex driving gear 3, an auxiliary transmission output shaft 4, a duplex driven gear 5, a first-stage deep groove ball bearing 6, Secondary deep groove ball bearing 7, shaft sleeve 8, shift lever 9, end cover 10, oil filling filter structure 11, quick installation adjustable rod structure 12 and oil filling detection needle structure 13, the auxiliary transmission input shaft 2 The lateral middle position bearing is connected to the middle position of the inner left wall of the transmission housing 1; the duplex driving gear 3 is key-connected to the right part of the outer wall of the auxiliary transmission input shaft 2; one end of the auxiliary transmission output shaft 4 passes through a The first-stage deep groove ball bearing 6 is installed on the inner left lower ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap