Energy-saving type spinning cloth processing device

A technology for textile fabrics and processing devices, applied in the field of energy-saving textile fabric processing devices, can solve the problems of poor drying effect of fabrics, affecting the quality of fabrics, large consumption of hot air, etc., achieving easy installation and operation, avoiding transition waste, and reducing waste of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

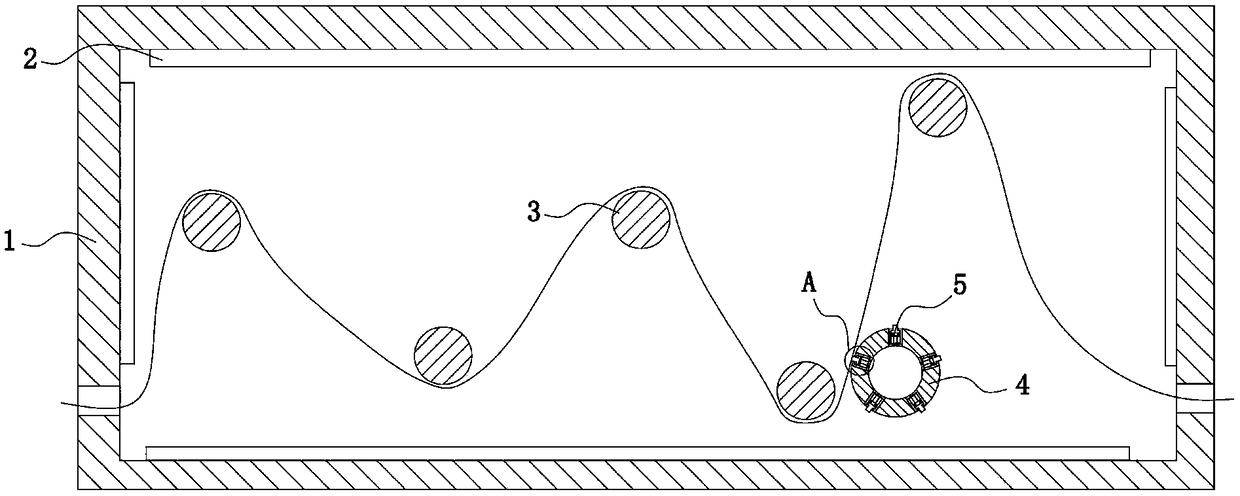

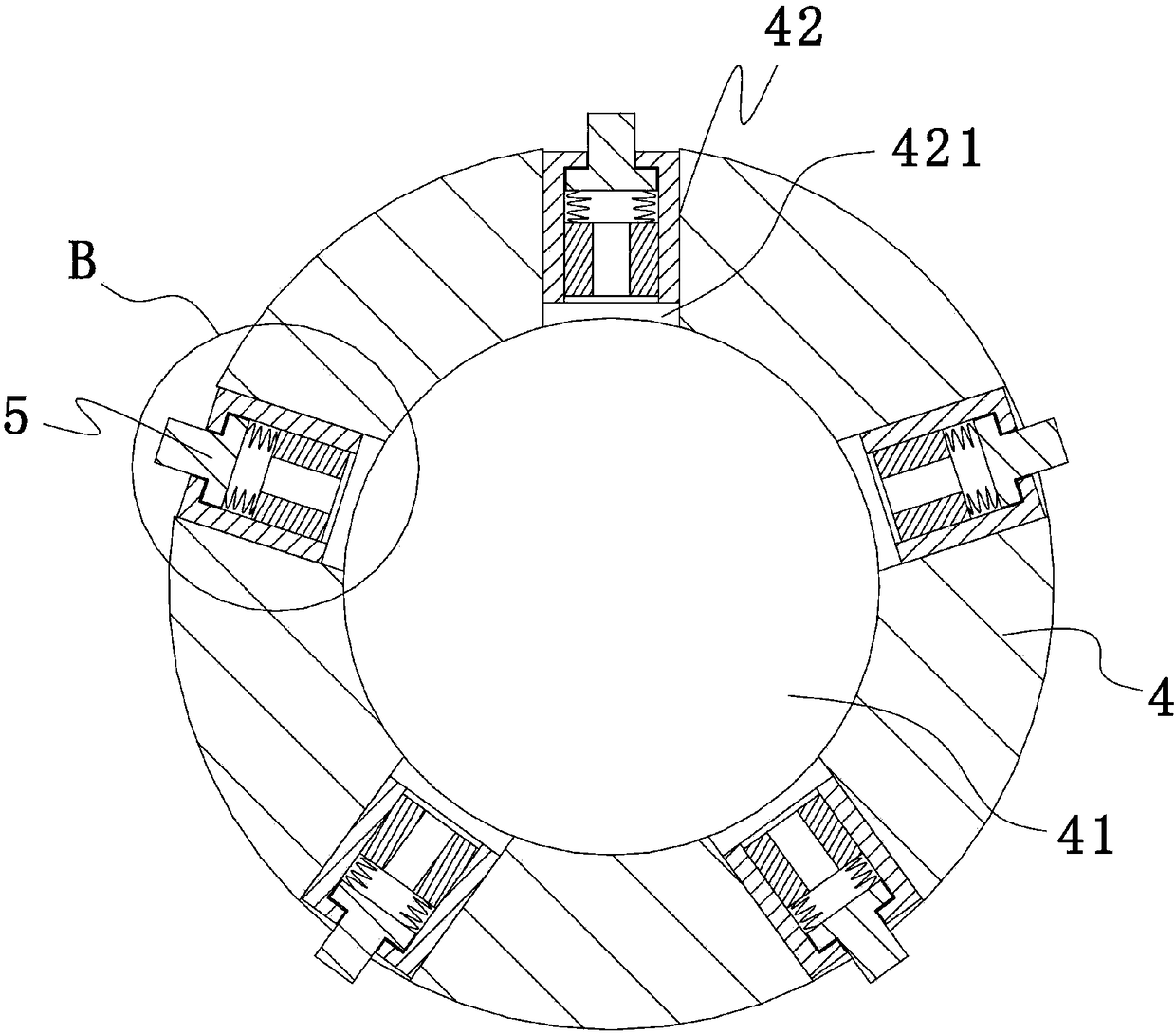

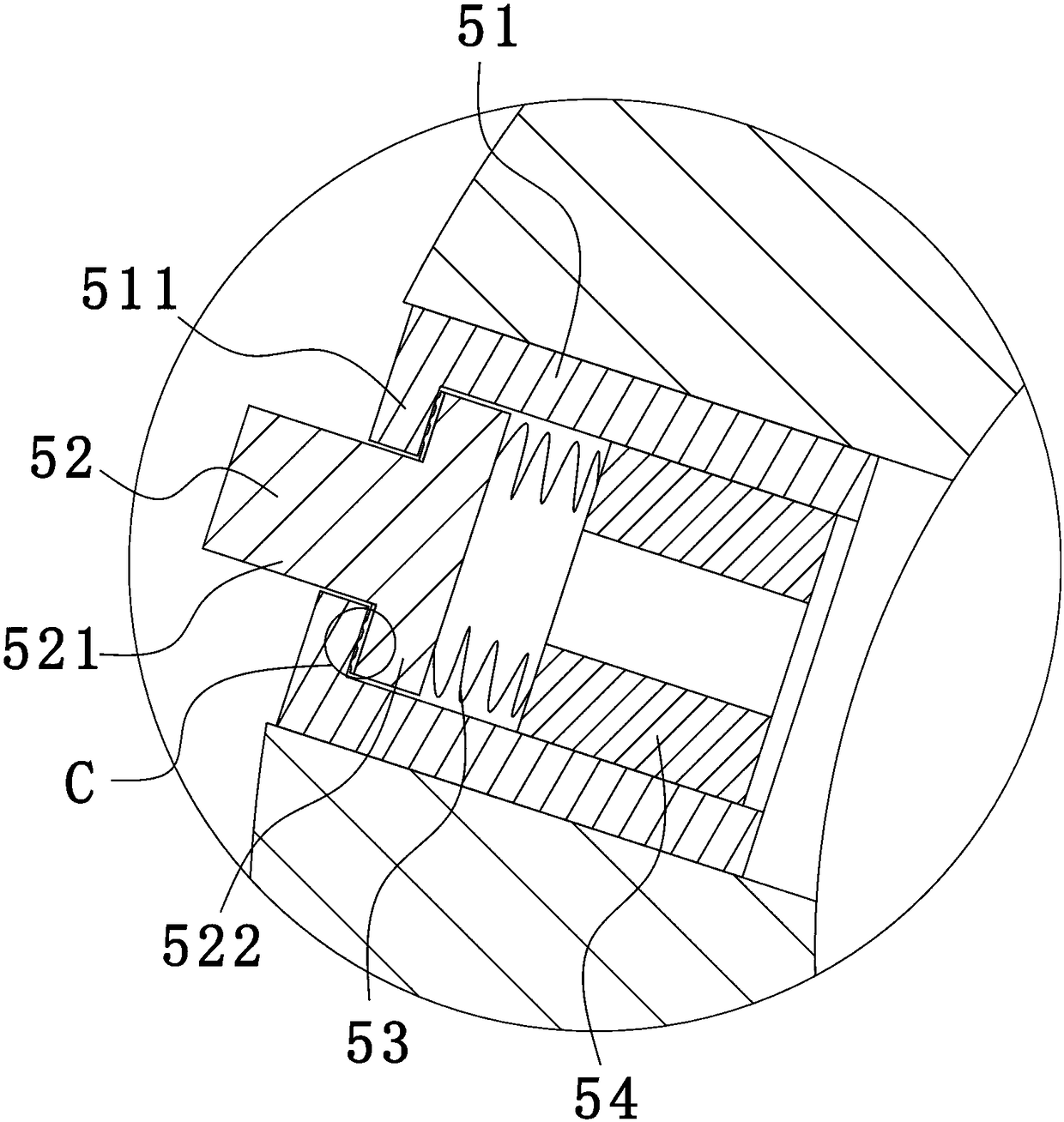

[0021] Such as Figure 1-7 As shown, an energy-saving textile fabric processing device includes an oven 1 made of stainless steel, a heating element 2 arranged on the inner wall of the oven, a plurality of cloth guide rollers 3 rotatably arranged in the oven, and a device capable of moving up and down. The drying roller 4 in the oven, the driving parts, the rotating drive device that can drive the drying roller 4 to rotate when the drying roller 4 moves up and down, and the one-way air outlet part arranged on the drying roller 4 5. The one-way air outlet part 5 can realize air outlet when being squeezed by external force; the heating element is a heating pipe, and the cloth g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com