System and method used for realizing online three-coordinate equipment measurement

A three-coordinate measurement and measurement system technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve problems such as inability to measure, distortion of measurement data, and accumulation of measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

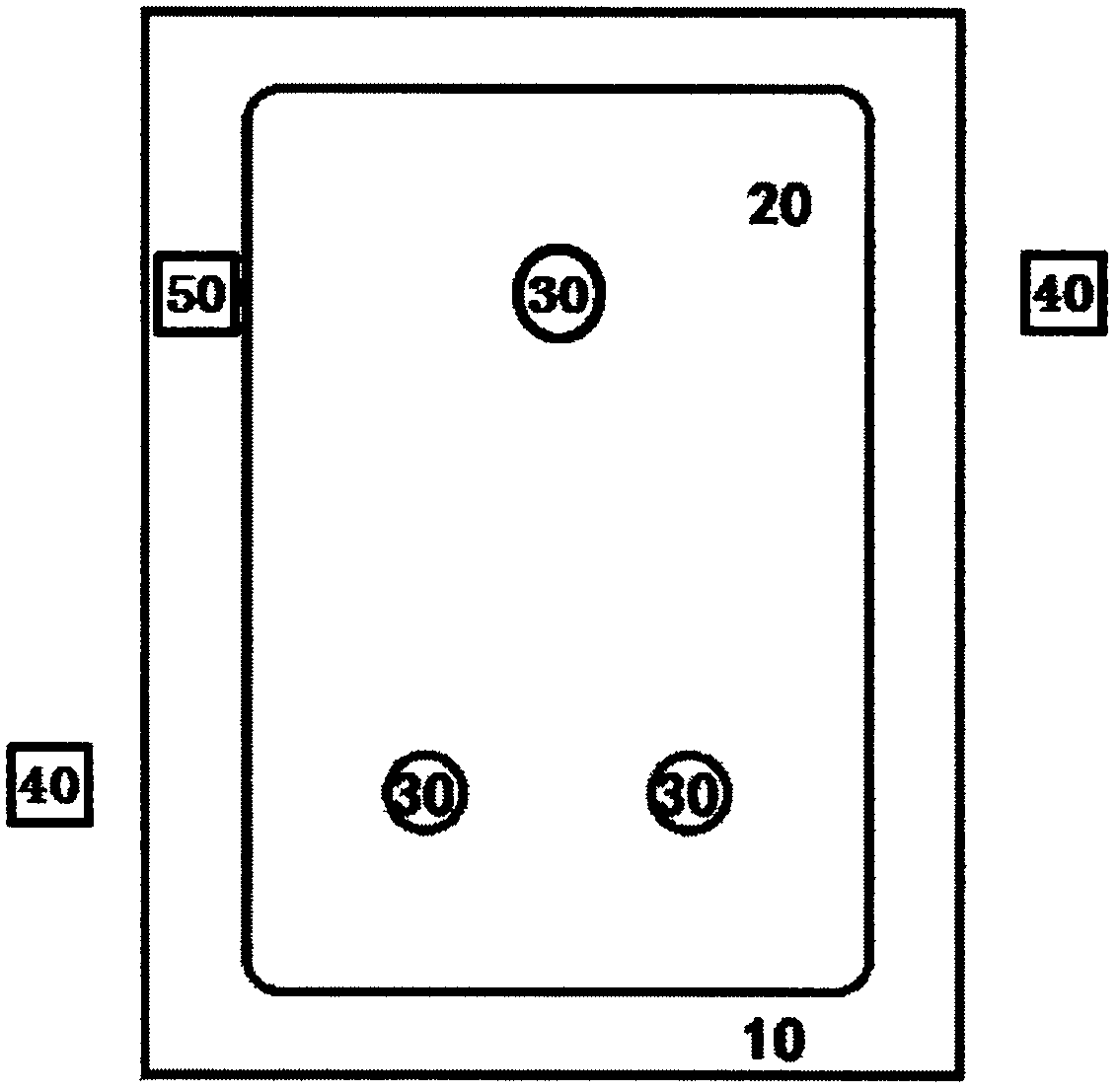

[0035] like figure 1 As shown, the online measurement system for three-coordinate equipment in this embodiment includes a body-in-white measurement platform 10, a body-in-white frame assembly 20, three standard balls 30, and a double cantilever three-coordinate The measuring device 40 is a portable laser measuring device 50; the steps of online and synchronous measurement of the double cantilever three-coordinate measuring device 40 and the portable laser measuring device 50 are as follows:

[0036] Use the double-cantilever three-coordinate measuring device 40 to establish the component coordinate system; within the measuring stroke range of the portable laser measuring device 50, fix at least 3 standard spheres 30, and the positions of the 3 standard spheres 30 should cover the measurement characteristic range to the greatest extent .

[0037] Measure the position of the center of the fixed standard ball 30 under the component coordinate system, and record the value;

[00...

Embodiment 2

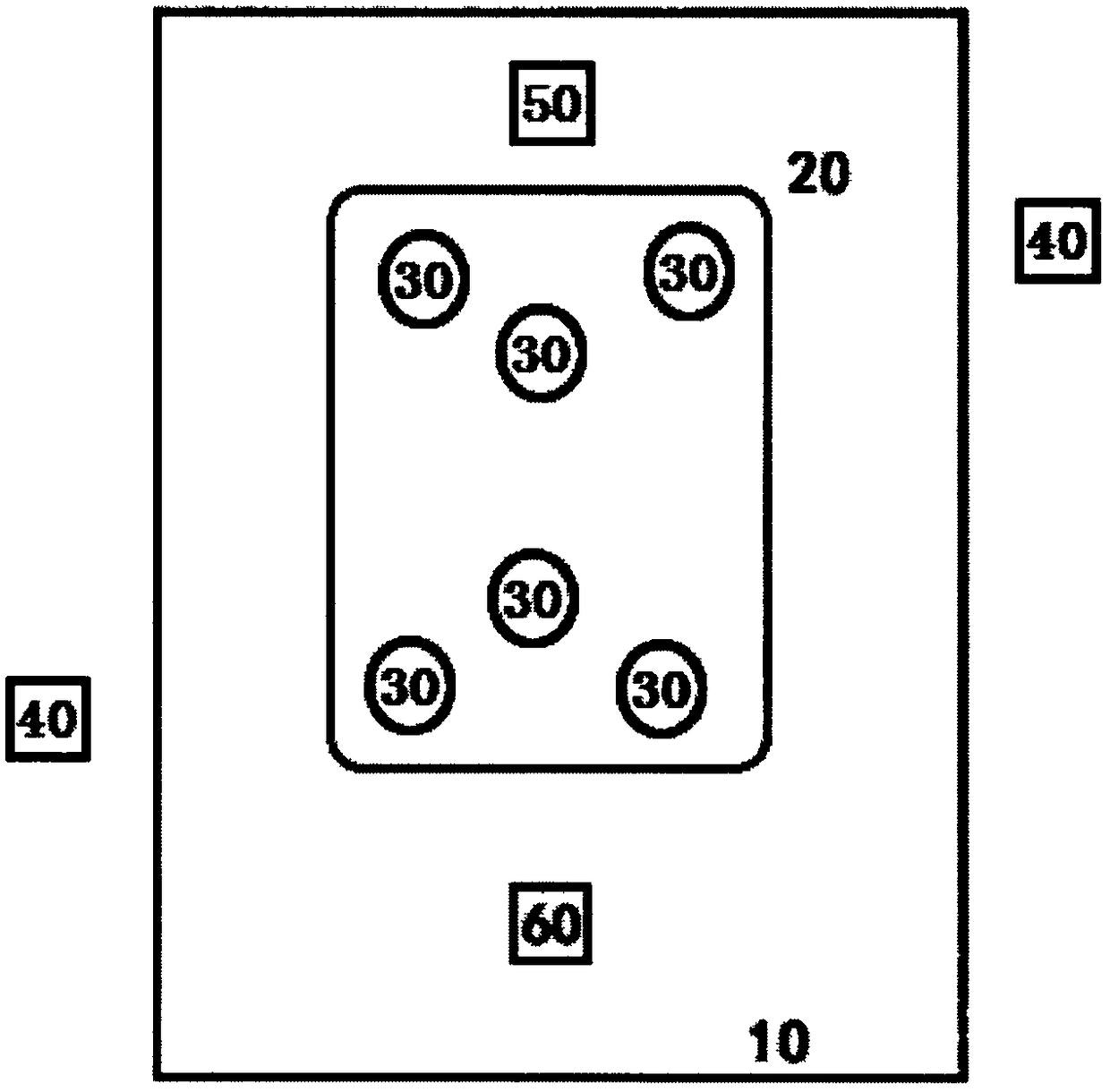

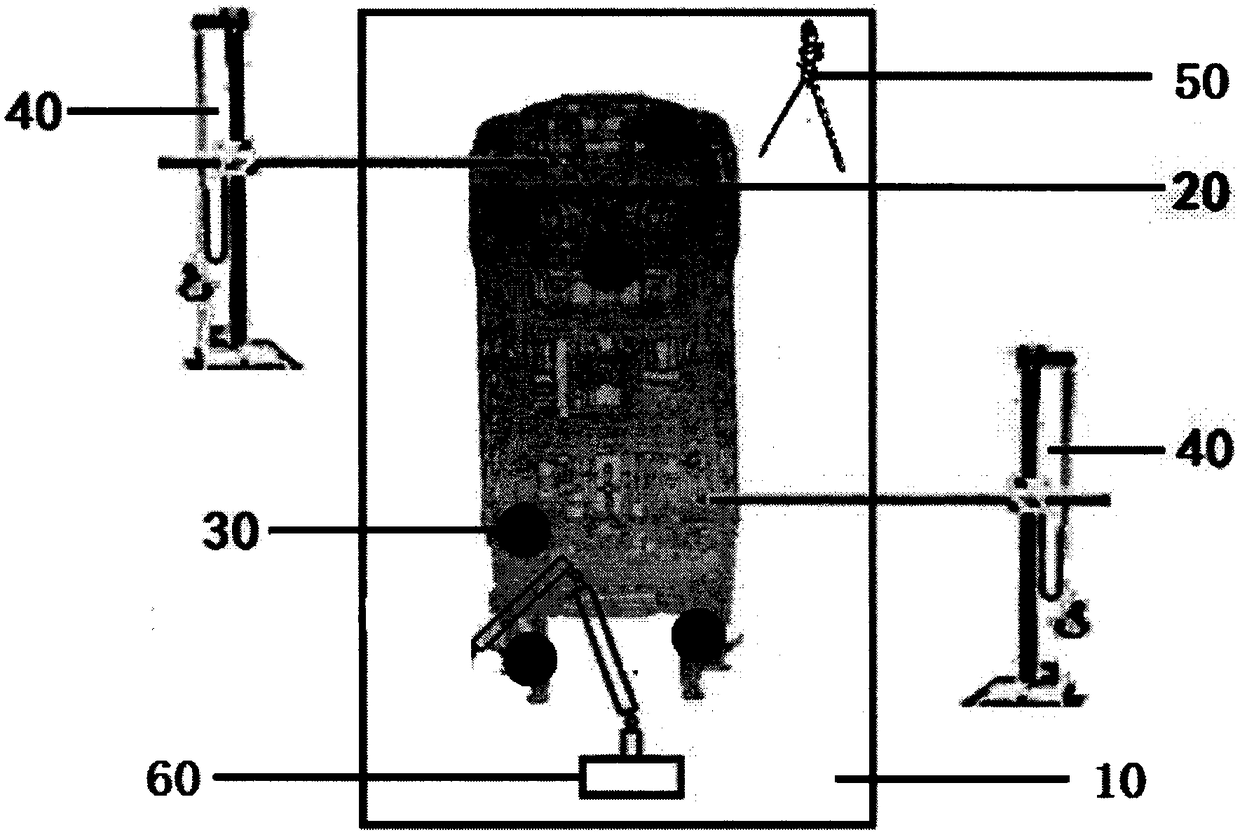

[0042] like Figure 2-3 As shown, the online measurement system for three-coordinate equipment in this embodiment includes a body-in-white measurement platform 10, a body-in-white frame assembly 20, six standard balls 30, and a double cantilever three-coordinate Measuring device 40, a portable laser tracker 50 and a portable multi-joint measuring device 60; the one double-cantilever three-coordinate measuring device 40 is located on the body-in-white measuring platform 10, and the portable multi-joint measuring device 60 is located on the body-in-white skeleton On the body-in-white measurement platform 10 at the front end of the assembly 20, the portable laser tracker measurement device 50 is located on the measurement platform 10 at the rear end of the body-in-white frame assembly 20, and the six standard balls 30 are also respectively arranged on the body-in-white frame assembly 20 The front end and the rear end, and any three of them are not on the same straight line. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com