Online monitoring method for metering performance of diaphragm gas meter

一种膜式燃气表、计量性能的技术,应用在流体密封性的测试、机器/结构部件的测试、测量装置等方向,能够解决下降、不能真正提高机电转换分辨率、扩大机电转换输出脉冲宽度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

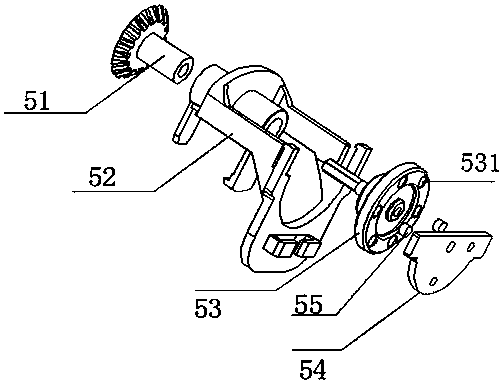

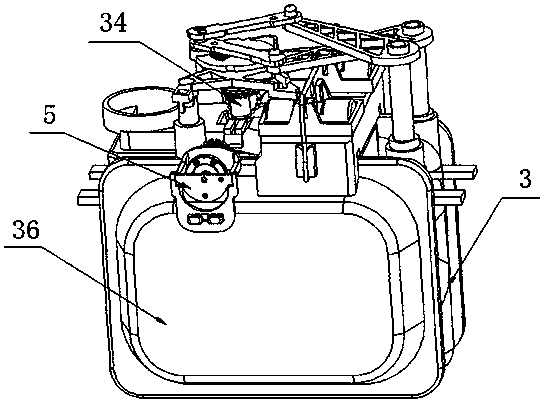

[0031] An on-line monitoring method for metering performance of a membrane gas meter, the electromechanical conversion device 5 is installed in the cavity of the gas meter casing 2, the core 3 in the cavity of the gas meter is provided with a film rotating shaft 34, and the film rotating shaft 34 is provided with There is a film rotating shaft gear; the transmission gear 51 is meshed with the film rotating shaft gear, a magnet 55 is arranged on the magnetic turntable 53, the magnetic switch is welded on the magnetic switch PCB board 54, and the magnetic switch PCB board 54 is vertically installed on the support 52, and The planes of the magnetic turntable 53 are parallel.

[0032] The electromechanical conversion device 5 includes a transmission gear 51 , a bracket 52 , a magnetic turntable 53 , a magnetic switch PCB 54 and a magnet 55 .

[0033] One revolution of the magnetic turntable 53 corresponds to the gas meter outputting a revolution volume of gas, that is, one output ...

Embodiment 2

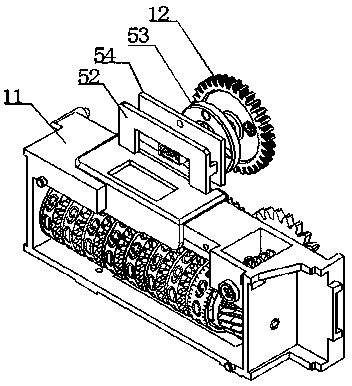

[0036] An online monitoring method for the metering performance of a membrane gas meter. The electromechanical conversion device 5 is installed outside the cavity of the gas meter casing 2. A metering chamber 1 is arranged outside the gas meter. The metering chamber 1 has a counter 11 and a The outer main gear 12 directly magnetically coupled with the outer film shaft gear of the watch movement 3; the magnetic turntable 53 is embedded on the outer gear 51 and rotates coaxially; the bracket 52 is fixedly installed on the counter 11, and the magnetic switch PCB board 54 is vertically installed The bracket 52 is parallel to the plane of the magnetic turntable 53 ; the magnetic turntable 53 is provided with a magnet 55 , and the magnetic switch is welded on the magnetic switch PCB 54 .

[0037] The electromechanical conversion device 5 includes a bracket 52 , a magnetic turntable 53 , a magnetic switch PCB 54 and a magnet 55 .

[0038]One revolution of the magnetic turntable 53 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com