Precast segmental prier component horizontal joint grouting and exhausting structure and grouting method

A technology of prefabricated assembling and splicing seams, applied in the direction of bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of not dense grouting joints, uneven top surface of grouting material splicing joints, residual air bubbles on the top surface of jointing joints, etc. , to achieve the effect of reducing residual bubbles, reducing adverse effects and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

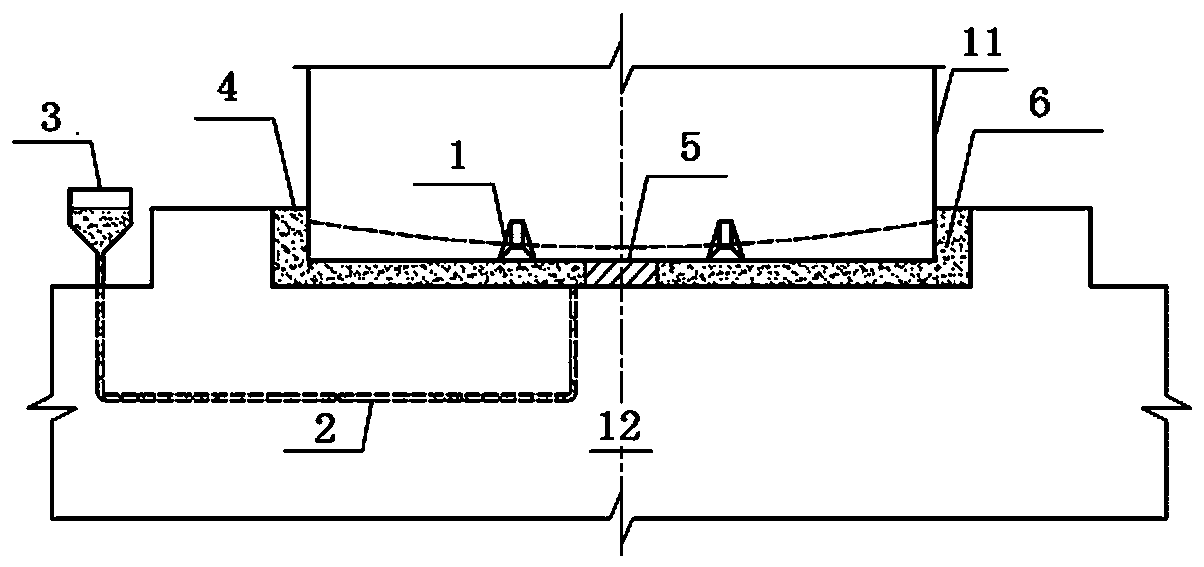

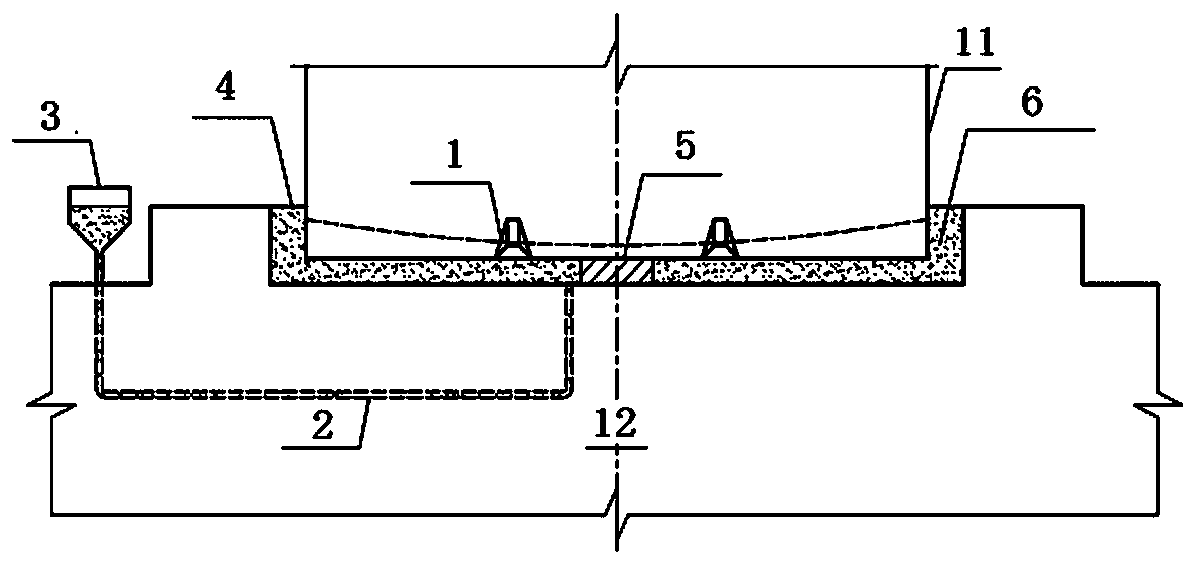

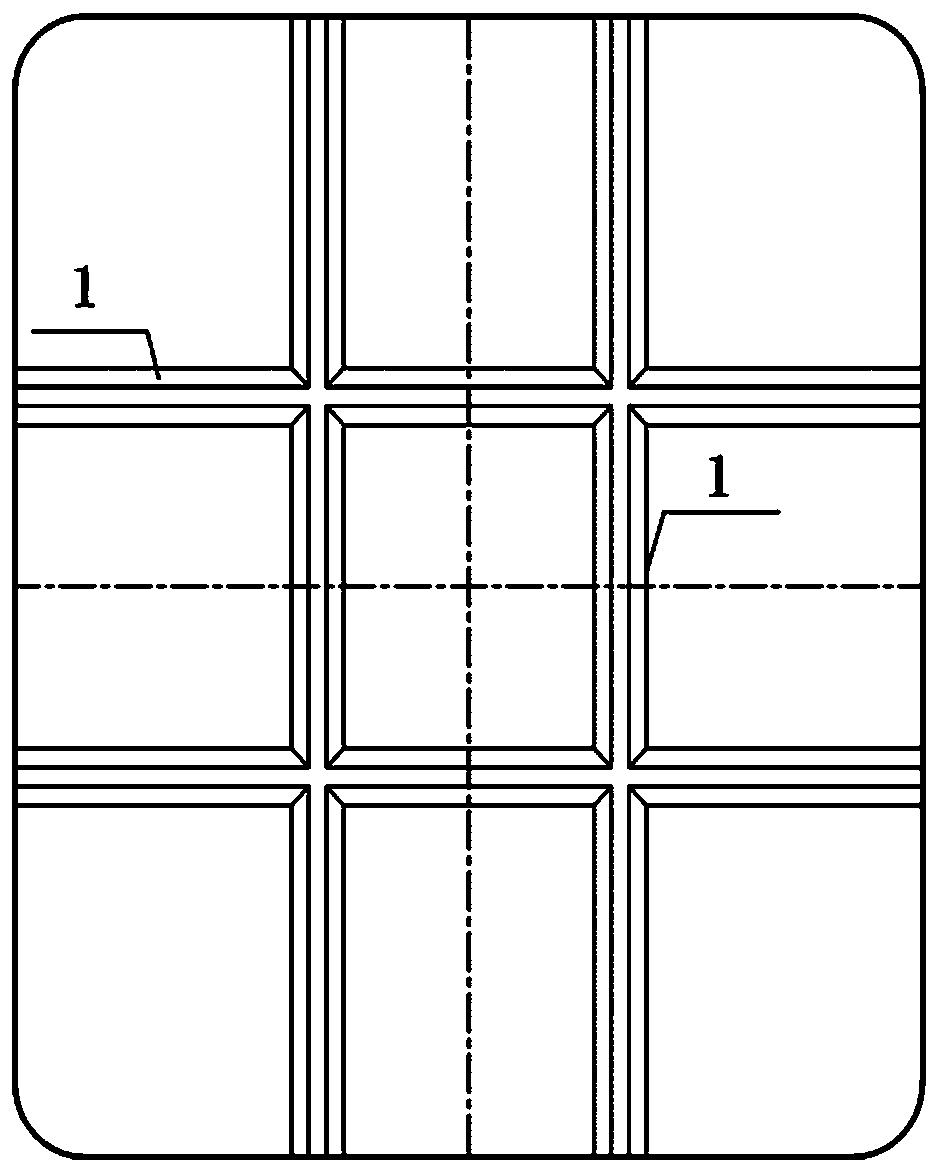

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] The figure includes exhaust groove 1, grouting pipe 2, grouting bucket 3, grouting pool 4, steel cushion block 5, high-strength grouting material 6, first annular steel formwork 7, sealing gasket 8, exhaust grouting pipe 9, second Annular steel formwork 10, pier column 11, cap 12, lower pier column 13, upper pier column 14, cover beam 15.

[0042] As shown in the figure, a prefabricated assembled bridge pier component horizontal joint grouting exhaust structure, the bridge pier component includes an upper component and a lower component, and a joint joint is formed between the corresponding joint surfaces of the upper component and the lower component, which is characterized in that One or more exhaust grooves are reserved on the splicing surface of the upper component, and the highest point of the exhaust groove communicates with the outside of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com