Check valve for preventing backflow

A technology of one-way valve and spool, applied in the direction of control valve, valve device, function valve type, etc., can solve the problems of high cost and difficult maintenance, and achieve the effect of reducing the conditions of use, cost and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

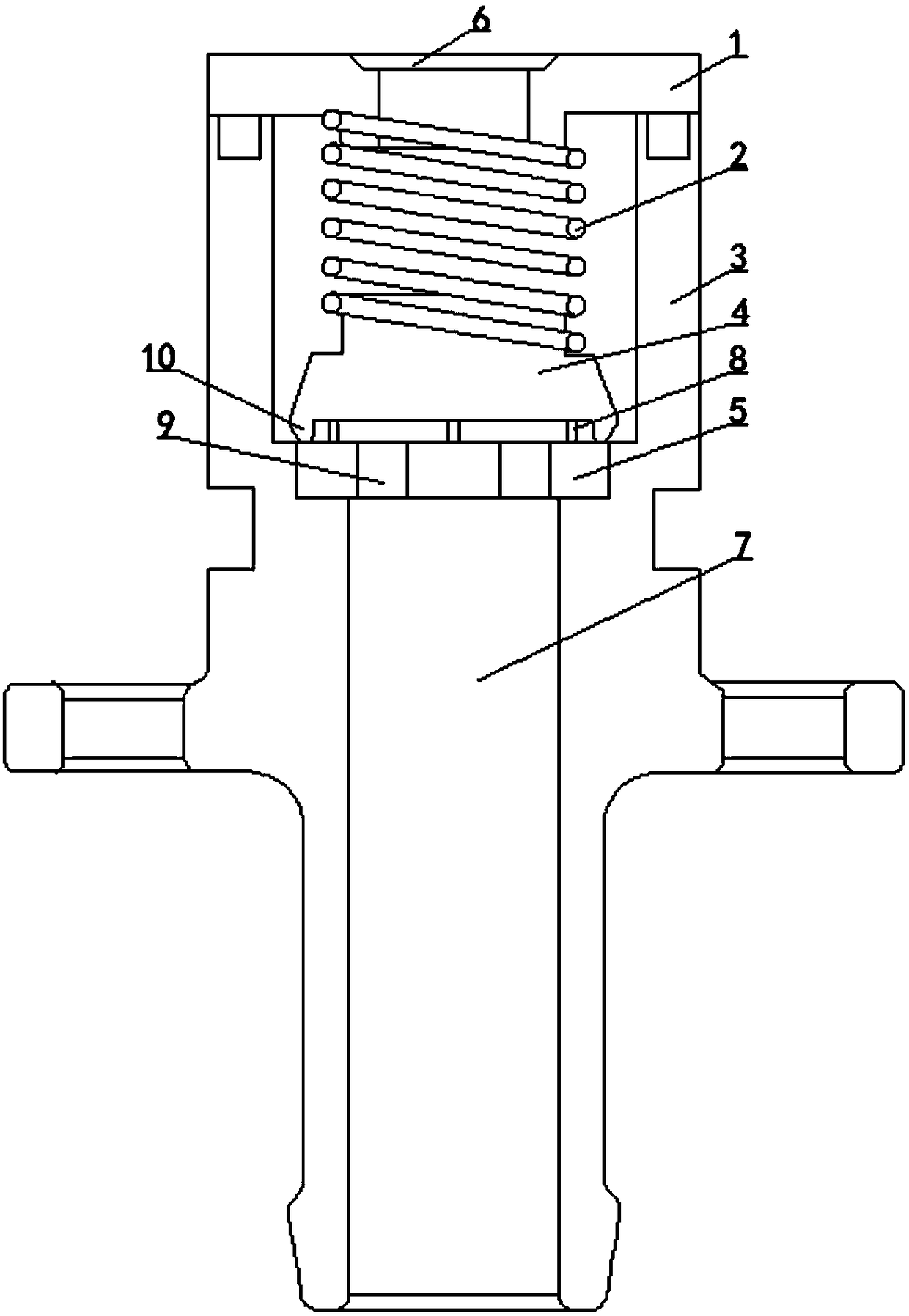

[0018] like figure 1 As shown, the one-way valve used to prevent backflow includes a valve body, a spring seat 1, a spring 2, a one-way valve body 3, a valve core 4, a valve core base 5, a fluid inlet 6, a fluid outlet 7, a closing rod 8, Valve core base air hole 9, the first layer of sealing ring 10, the valve body includes a cylindrical channel and a check valve body 3, the check valve body 3 is a cylindrical cavity, the cylindrical channel One end is seamlessly connected with one end of the cylindrical cavity, the spring seat 1 is arranged at the other end of the cylindrical cavity connecting the cylindrical passage end, the fluid inlet 6 is arranged outside the spring seat 1, and the spring The middle part of the seat 1 is hollow and communicates with the fluid inlet 6; the fluid outlet 7 is a cylindrical channel connected to the other end of the cylindrical cavity end; the valve body base 5 is arranged on the cylindrical channel connected to the cylindrical cavity The en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com