Rotor of permanent magnet motor

A permanent magnet motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electrical components, etc., can solve the problems of high price, easy to fall off, etc., to improve performance, improve torque coefficient, easy and reliable installation and fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

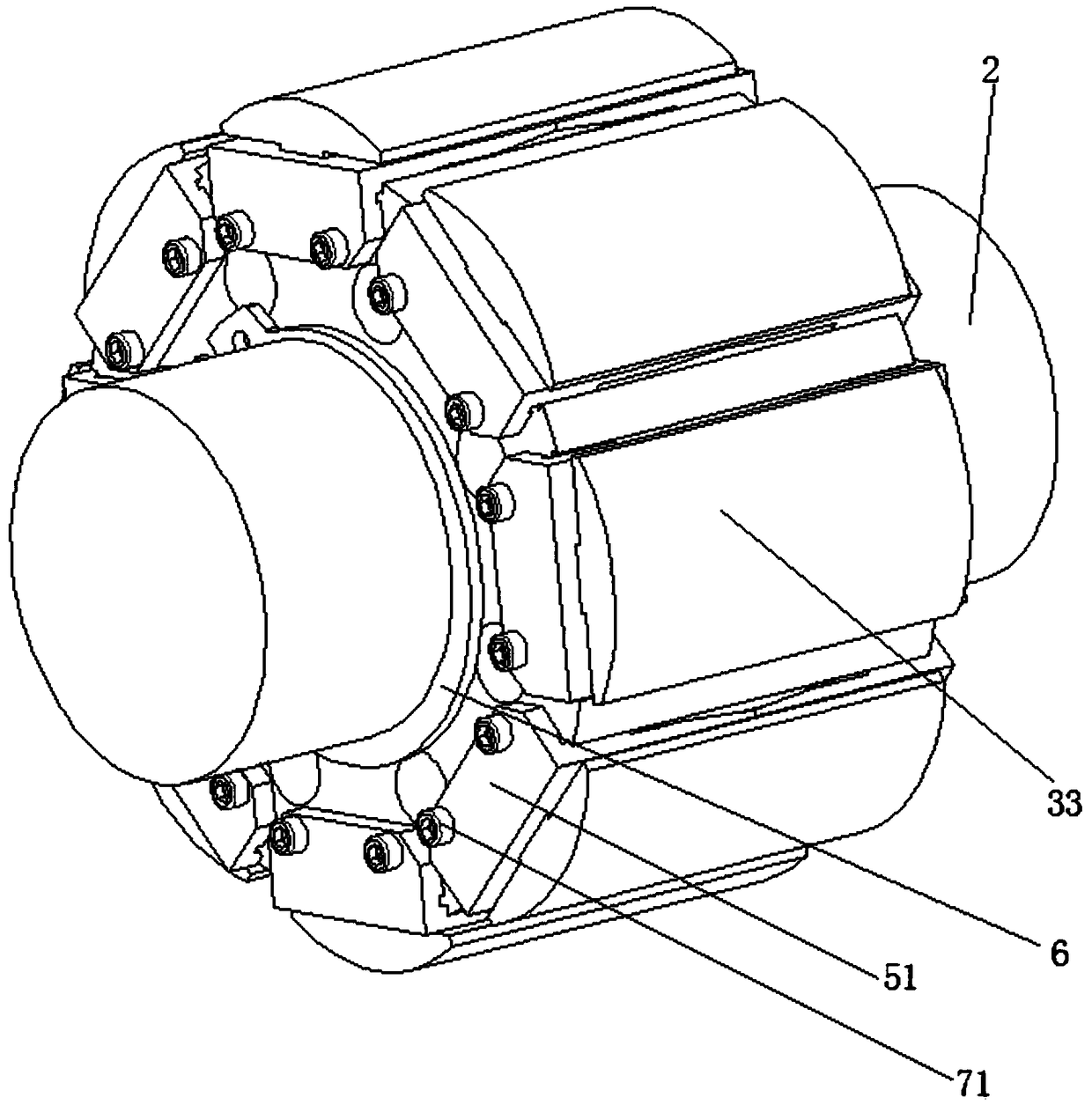

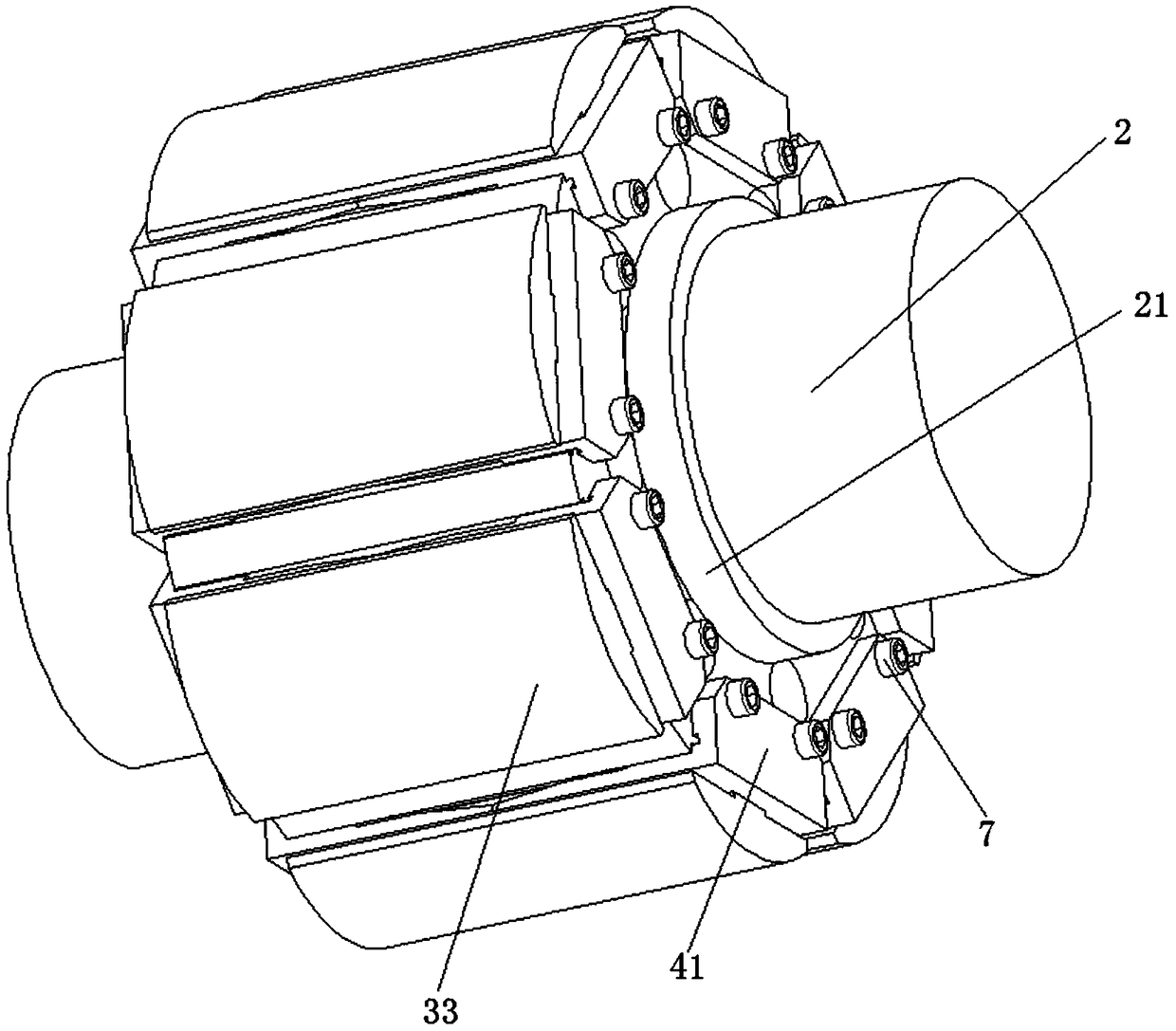

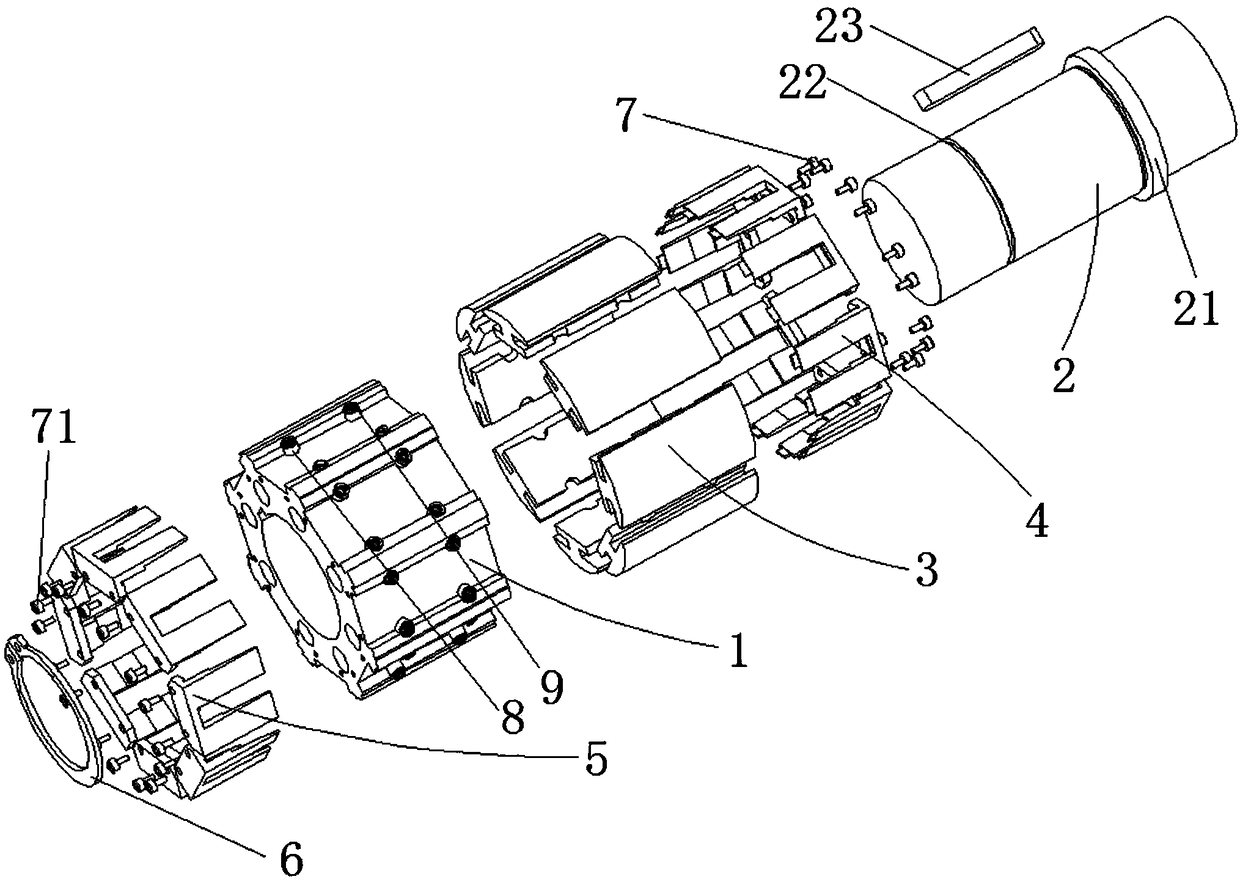

[0034] Such as Figure 1 to Figure 16 As shown, a permanent magnet motor rotor includes a rotor core 1, a shaft 2, a magnetic steel 3, a front baffle 4 and a rear baffle 5, and the center of the rotor core 1 is provided with a shaft 2 that is tightly fitted and pressed into it. The shaft hole 14, the outer edge of the rotor core 1 is evenly distributed in the circumferential direction and the magnetic steel groove 11 runs through the front and rear. The outer edge of the rotor iron core 1 is located on the upper end of the magnetic steel groove 11. The left and right sides are symmetrically provided with pressing tables 12. The pressing table 12 runs through the front and rear end faces of the rotor core 1. Two pin slots 13 are provided at the junction of the press table 12 and the magnetic steel slot 11 on each side, and the press table 12 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com