Magnetic steel fixing structure for permanent magnet rotor

A permanent magnet rotor and fixed structure technology, applied in the field of motor parts, can solve the problems of high price and easy falling off, and achieve the effects of low cost, improved performance, and convenient installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

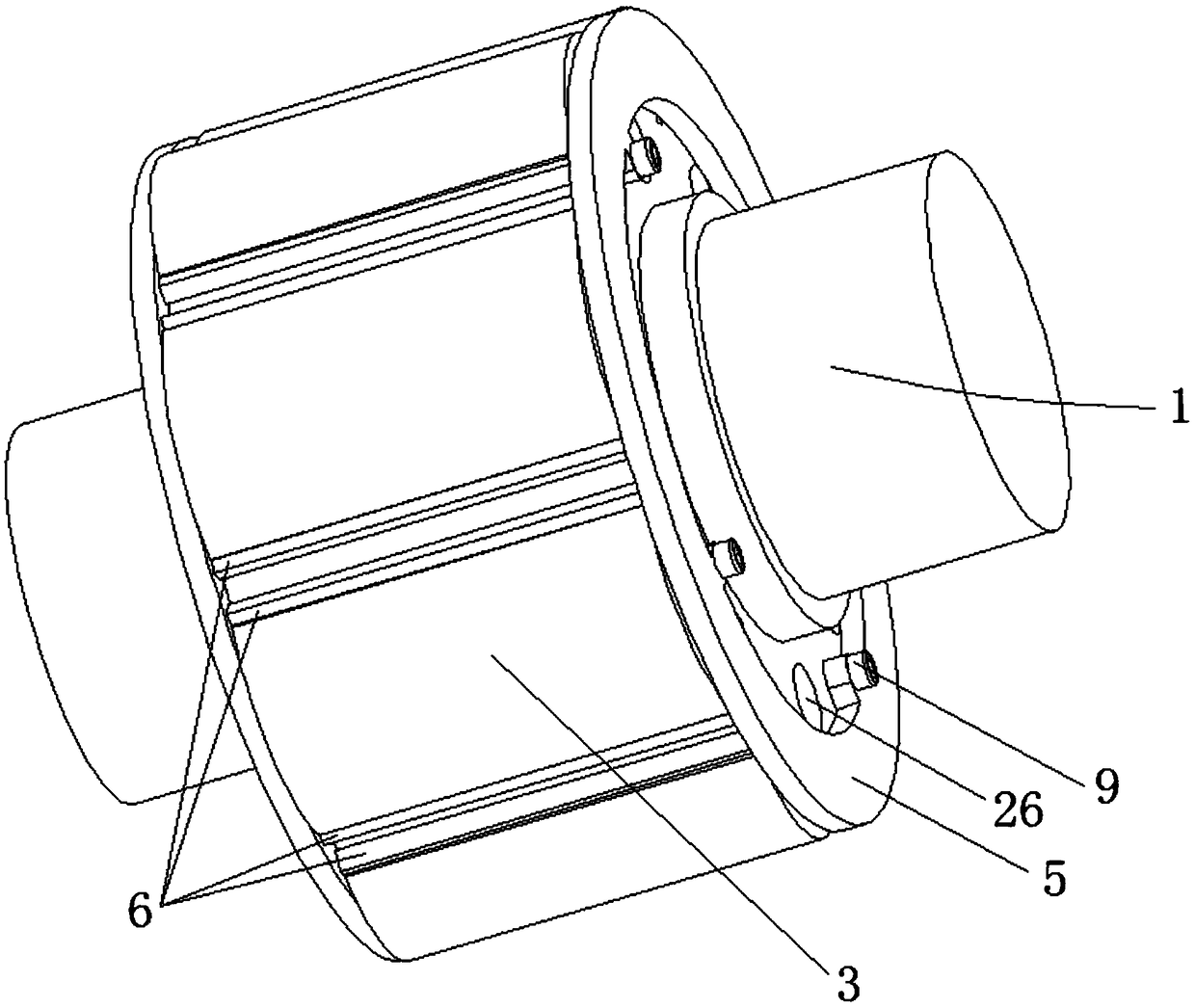

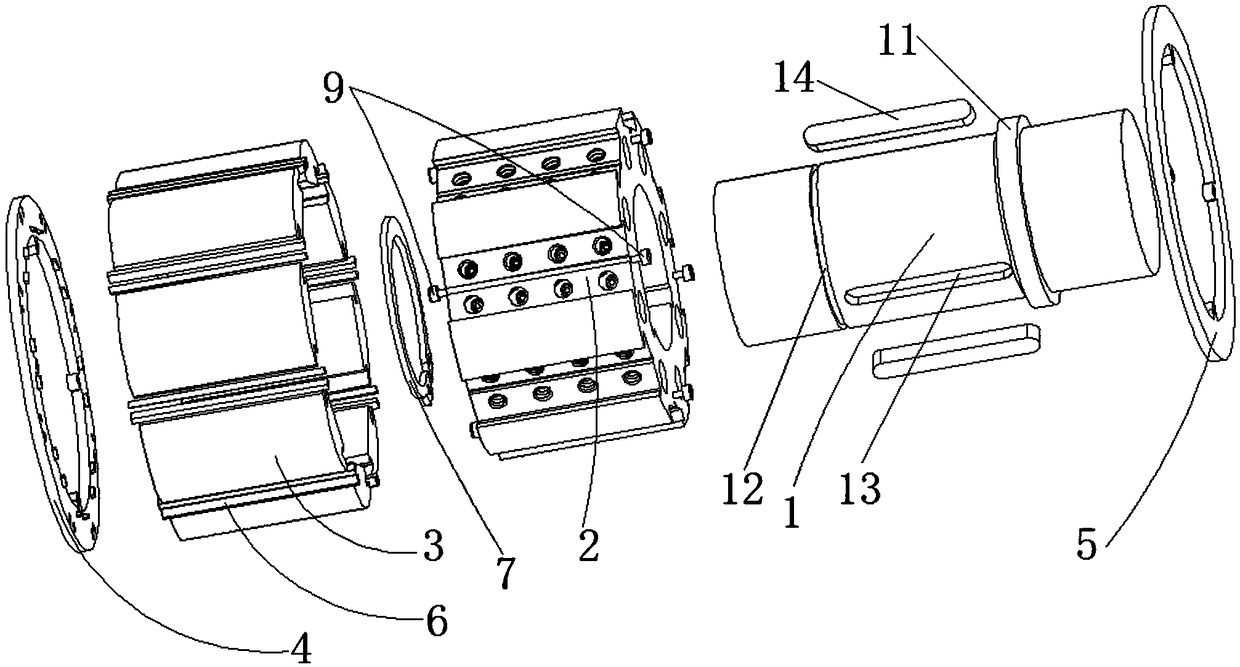

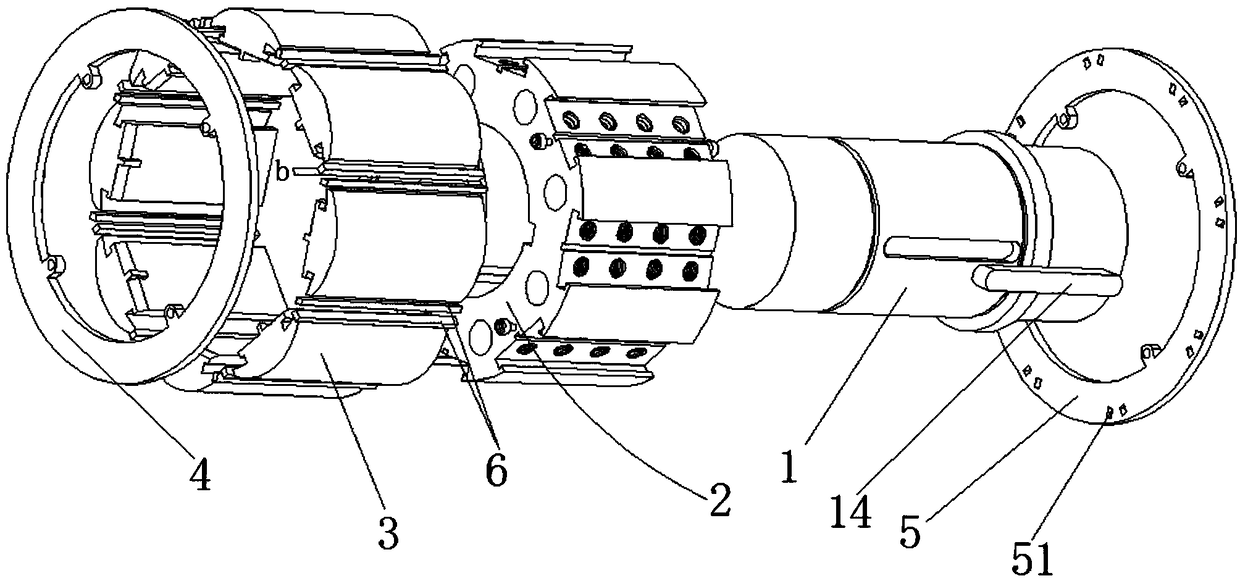

[0031] Such as Figure 1 to Figure 14 As shown, a magnetic steel fixing structure of a permanent magnet rotor includes a shaft 1, a rotor core 2 sleeved on the outer wall of the shaft 1, and a magnetic steel 3 evenly distributed on the rotor core 2, the shaft 1 The outer wall and the inner wall of the rotor core 2 are connected by a key 14, the outer wall of the shaft 1 is provided with a first keyway 13, the inner wall of the rotor core 2 is provided with a second keyway 24, and the first keyway 13 and The second key groove 24 cooperates to form a space for the insertion of the key 14, so that the rotation of the shaft 1 drives the rotor core 2 to rotate together. The number of the keys 14 is two and distributed at 120 degrees, which ensures the transmission of torque without reducing the shaft 1. The intensity of (relative to the situation that tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com