Cogging-free disc type permanent magnet motor

A permanent magnet motor, no cogging technology, applied in magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of disk motor load capacity and efficiency limitations, large motor stator heating, weak overcurrent capability, etc. Small equivalent air gap, strong overcurrent capability, and the effect of improving motor torque coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

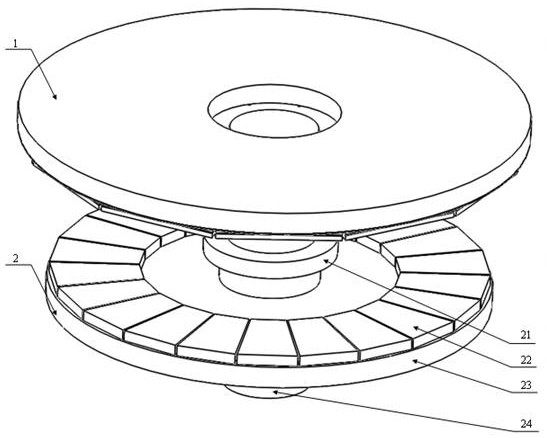

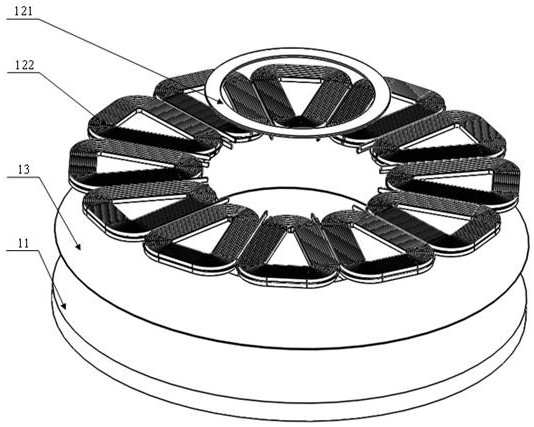

[0026] combine figure 1 and figure 2 As shown, a non-cogged disc permanent magnet motor of the present invention includes a stator 1 and a rotor 2 . The stator 1 includes a stator yoke 11, a disc winding 12 and a yoke insulating layer 13. The disc winding 12 is installed on the end face of the stator yoke 11, and a yoke insulating layer 13 is arranged between the two to provide electrical insulation. role. The rotor 2 includes a bearing 21, a magnetic tile 22, a rotor disk 23 and a rotor shaft 24, the rotor shaft 24 is supported by the bearing 21, the rotor disk 23 and the rotor shaft 24 are fixedly installed, the magnetic tile 22 is arranged on the rotor disk 23, and along the rotor disk 23 evenly distributed circumferentially. After the stator 1 and the rotor 2 are installed, the disc windings 12 and the magnetic tiles 22 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com