Slotless motor with low cogging torque and torque ripple formed by magnetically conductive magnet wires

An electromagnetic wire and magnetic conduction technology, which is applied in the field of electromagnetic wire and slotless motors, can solve the problems of increasing the amount of permanent magnet materials used in permanent magnet motors, limitations and restrictions on the use of slotless motors, and poor performance of slotless asynchronous motors. Achieve the effect of eliminating radial electromagnetic excitation force, eliminating cogging torque and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

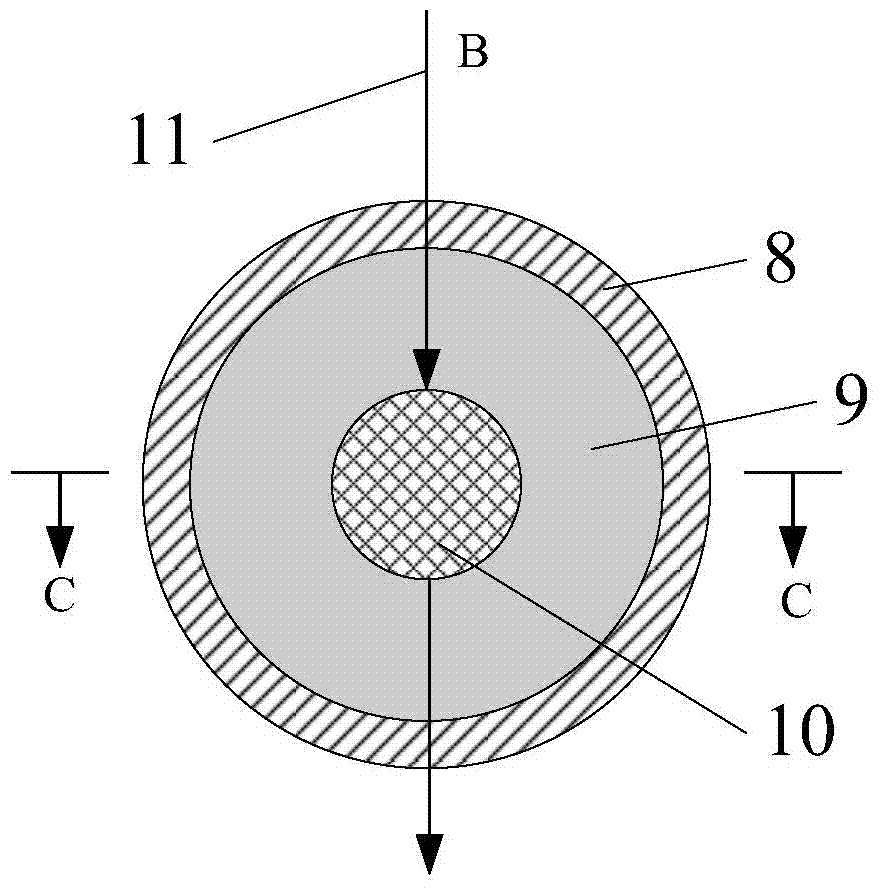

[0028] Embodiment one: if image 3 , Figure 4 As shown, the magnetically permeable magnet wire includes a first insulating layer 8 , a conductive layer 9 and a magnetically permeable layer 10 arranged in sequence from outside to inside. The cross-section of the first insulating layer 8 is similar to the cross-section of the insulating layer in ordinary wires, which is a ring structure; the conductive layer 9 is made of copper material and is located in the first insulating layer 8. The cross-section of the conductive layer 9 also adopts a ring structure, which has a certain The cross-sectional area of the current passes through; the magnetic permeable layer 10 is located in the conductive layer 9, adopts a columnar structure, and has a certain area for passing the magnetic flux. The thickness of the first insulating layer 8 is selected according to the performance of the insulating material and the difference of the applied voltage level. When the current passing through ...

Embodiment 2

[0032] Embodiment two: if Figure 5 As shown, the structure of the magnetically permeable magnet wire in this embodiment is similar to the structure of the magnetically permeable magnet wire in the first embodiment, and also includes the first insulating layer 8, the conductive layer 9 and the magnetically permeable layer 10. The difference is that this embodiment The electromagnetic magnetic wire in this example also includes a second insulating layer 12 . Both the conductive layer 9 and the magnetic permeable layer 10 adopt a rectangular structure, and the conductive layer 9 is arranged laterally side by side with the magnetic permeable layer 10 after being wrapped with the first insulating layer 8 . A second insulating layer 12 is wrapped outside the conductive layer 9 wrapped with the first insulating layer 8 and the magnetically permeable layer 10, as a whole magnetically permeable magnet wire. The first insulating layer 8 can also be omitted, that is, after the conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com