A tire with radial or bias carcass

A tire and carcass technology, which is applied to tire parts, tire tread/tread pattern, tire sidewall, etc., can solve the problems of adverse impact on tire aesthetics, insufficient air discharge efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

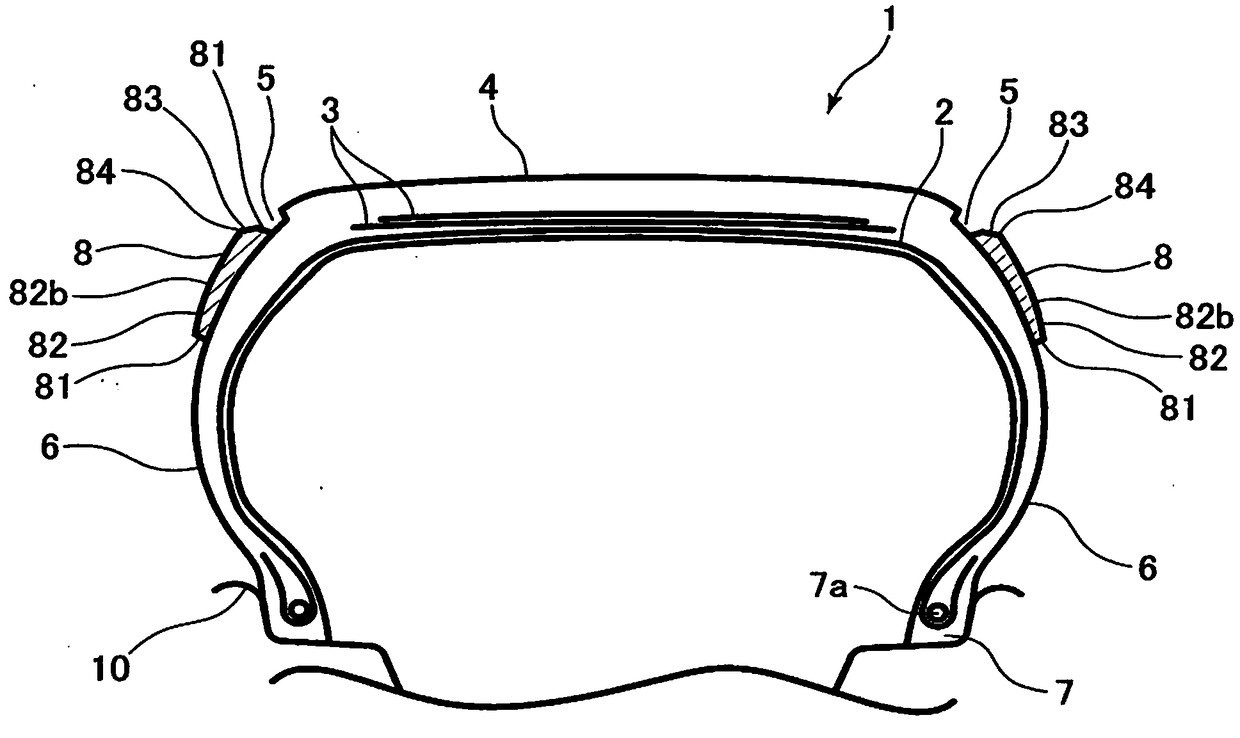

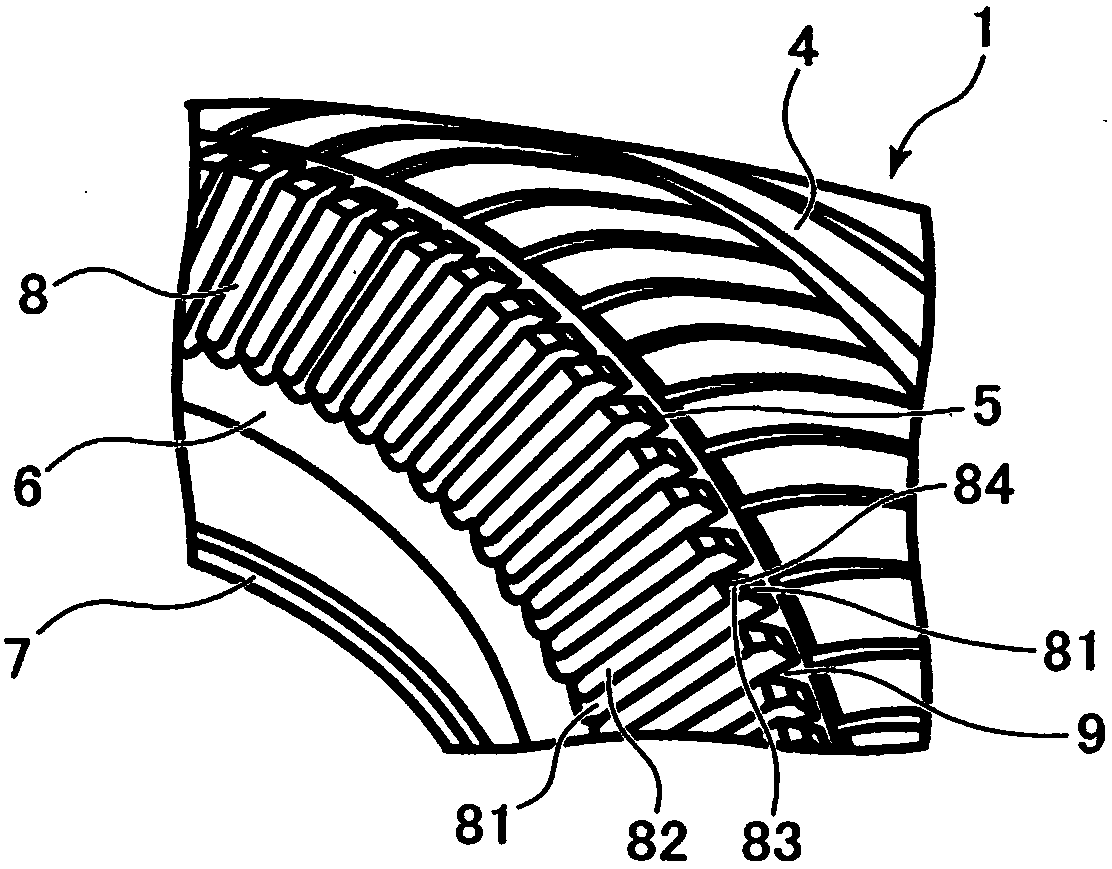

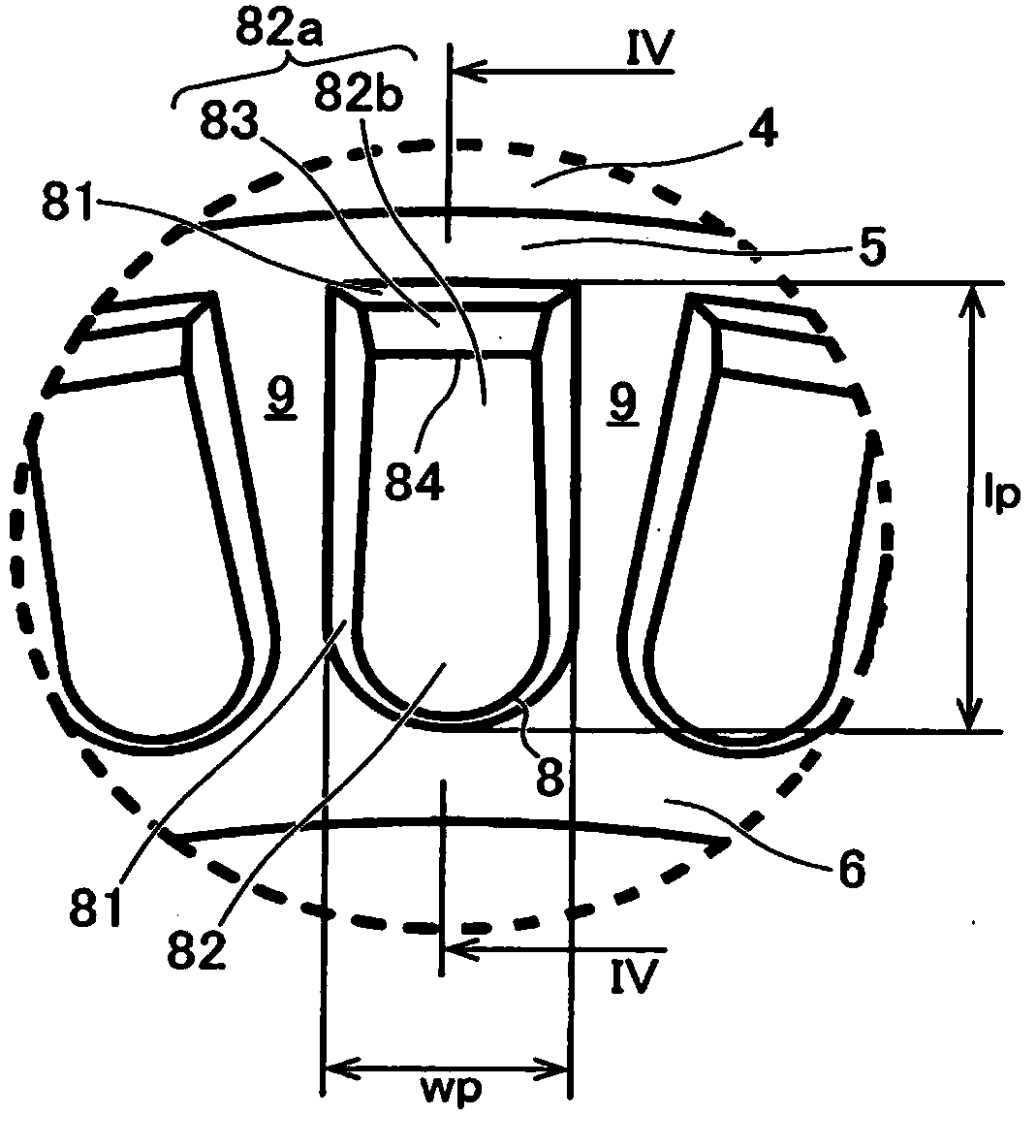

[0071] will refer to figure 1 , figure 2 , image 3 and Figure 4 A tire according to a first embodiment of the present invention is described. figure 1 is a schematic cross-sectional view of a mounted rolling assembly comprising a rim 10 and a tire 1 according to a first embodiment of the invention. figure 2 is a schematic perspective view of a part of the tire 1 according to the first embodiment of the present invention. image 3 is an enlarged schematic view of a part of the side wall 6 according to the first embodiment of the present invention. Figure 4 is along image 3 A cross-sectional view taken along line IV-IV in .

[0072] Tire 1 is of size 205 / 55R16 and comprises a carcass reinforcement (carcass reinforcement) 2, a crown reinforcement (crown reinforcement) 3 and a tread 4, said crown reinforcement 3 being arranged on the carcass rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com