Method of manufacturing seal assembly with locator

A technology for sealing components and positioners, which can be used in engine sealing, sealing devices, vehicle parts, etc., and can solve the problems of high scrap rate and expensive processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

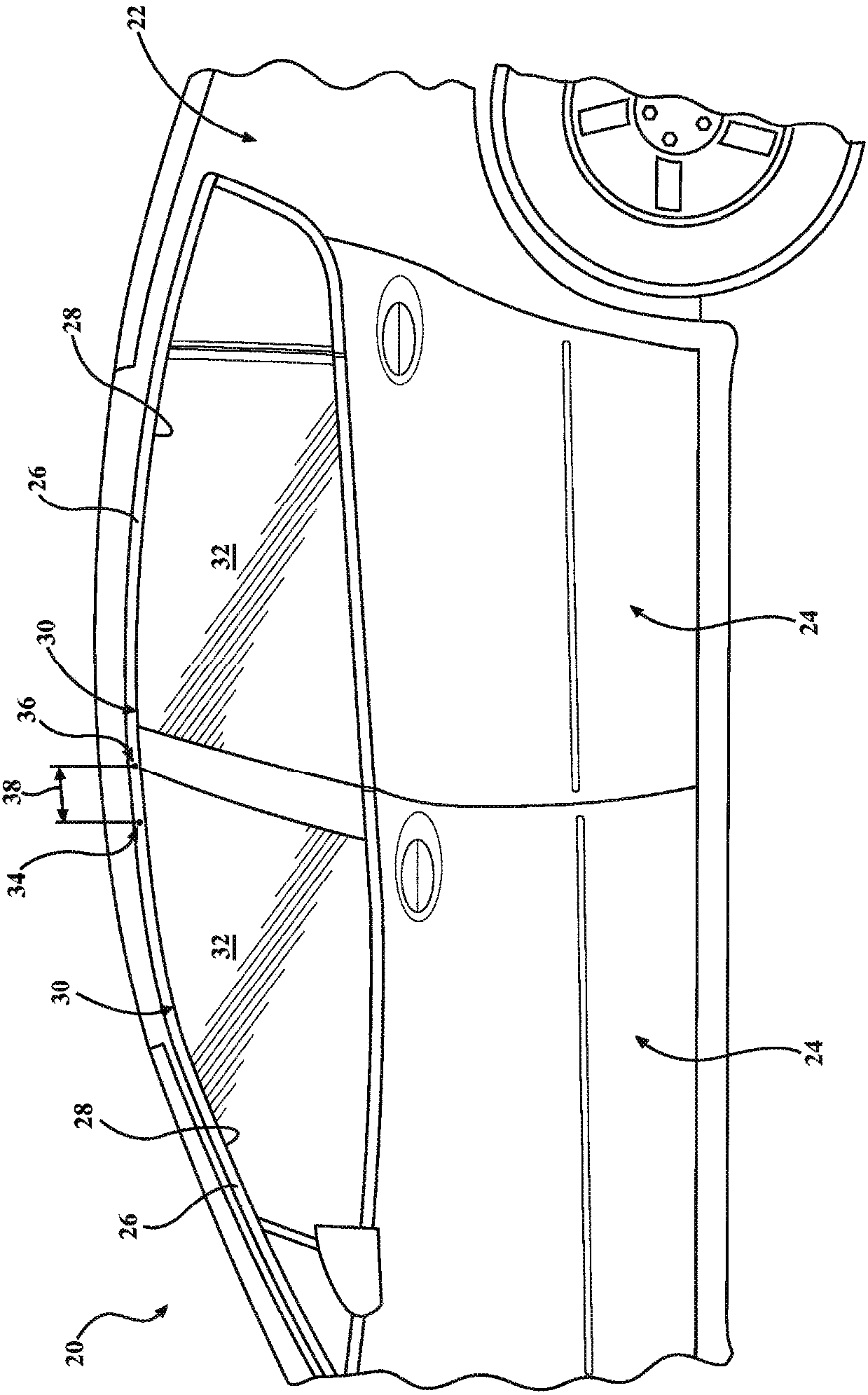

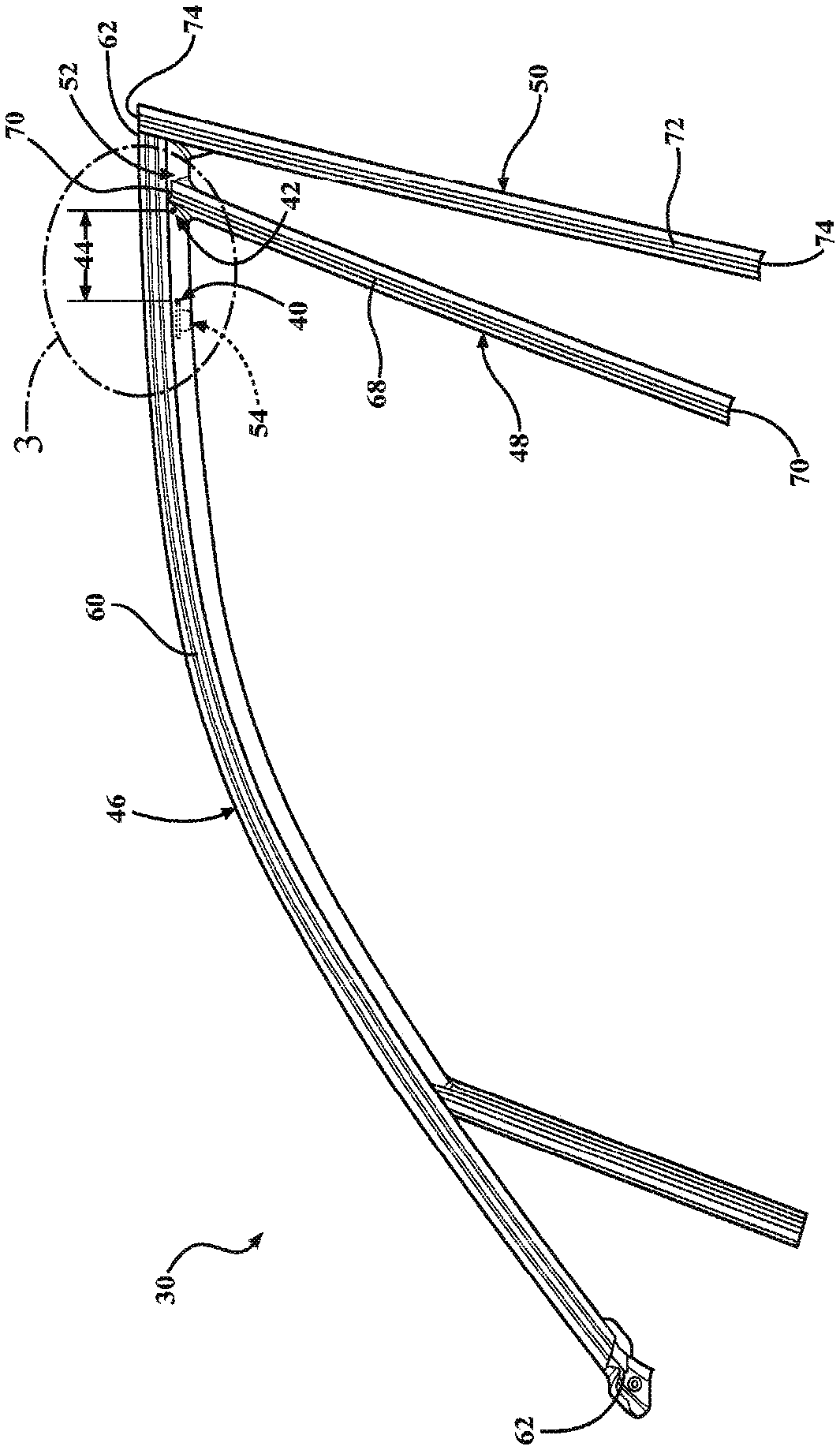

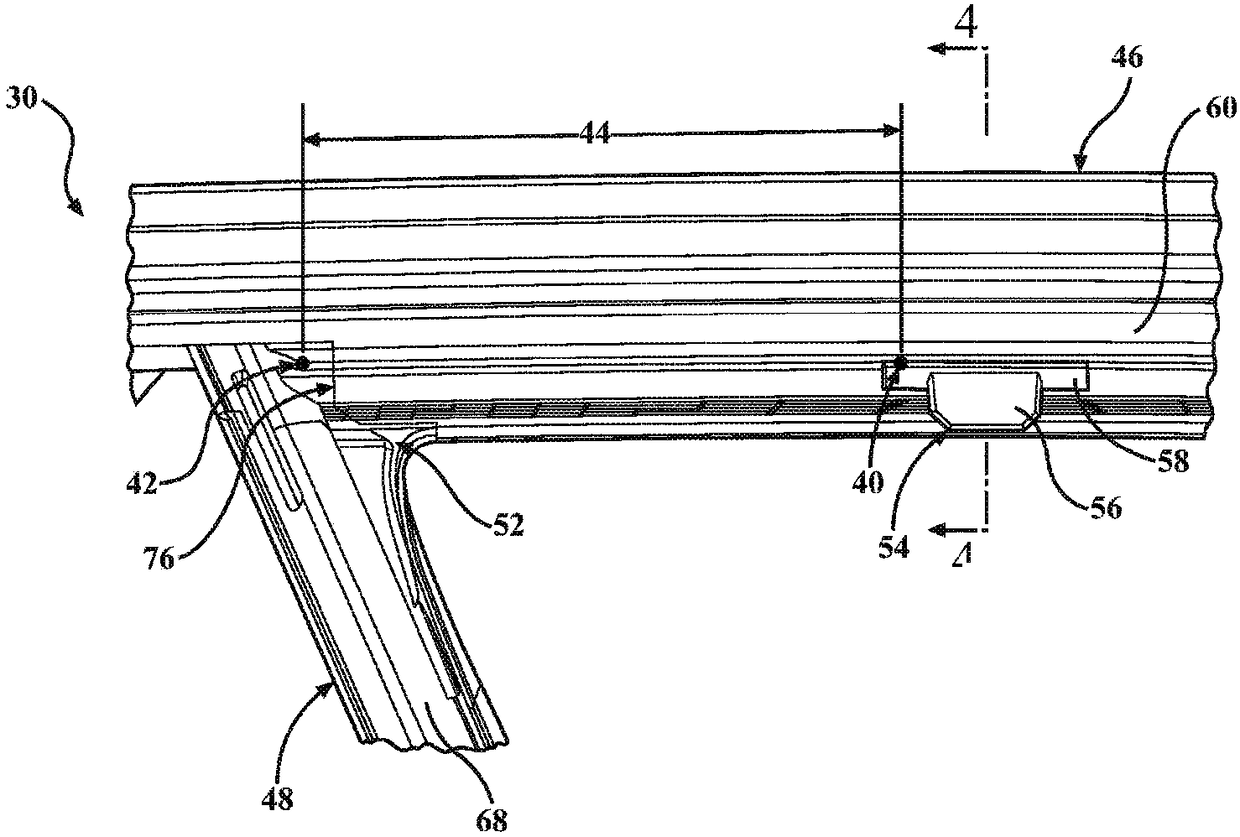

[0025] Referring now to the drawings, in which like numerals designate corresponding parts throughout the several views, in figure 1 20 in place shows a part of the car passenger vehicle. The vehicle 20 has a body generally indicated at 22 and a plurality of doors 24 coupled to the body 22 . Each of the doors 24 has a window frame 26 defining a window 28 and a seal assembly 30 adjacent to the window frame 26 . In the exemplary embodiment illustrated herein and depicted throughout the drawings, the seal assembly 30 is implemented as a window seal assembly 30 that is coupled to the window frame 26 and extends along at least a portion of the window frame 26, as described in more detail below. describe. However, those of ordinary skill in the art will appreciate that the seal assembly 30 may be implemented in many different ways for different vehicle 20 applications or for different types of vehicles 20 without departing from the scope of the present invention. Additionally, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com