Air conditioner heat-exchanger

A technology for heat exchangers and air conditioners, which is applied in heat exchange equipment, moving pipe heat exchangers, air conditioning systems, etc., and can solve problems such as complex assembly of return hoses, reduced work efficiency, and freezing of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

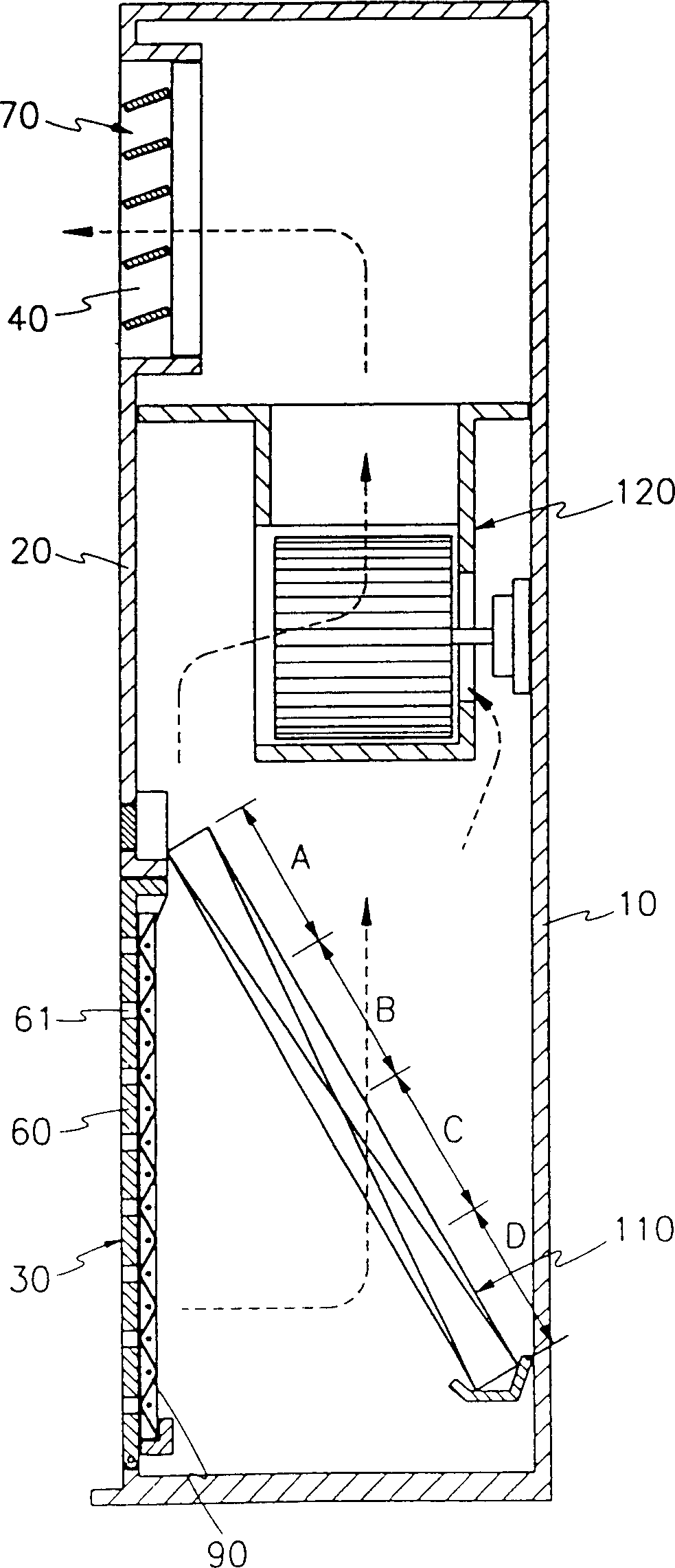

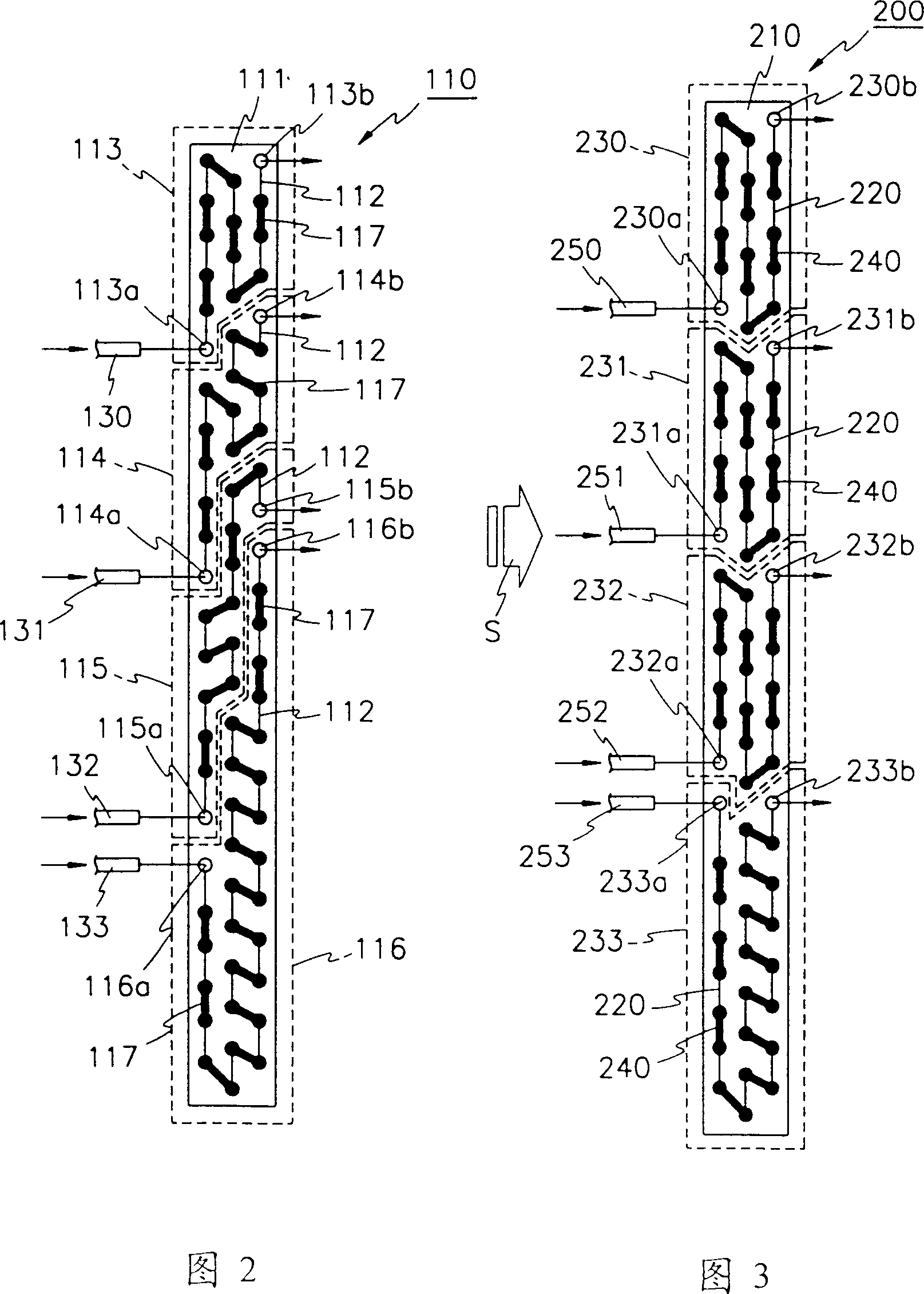

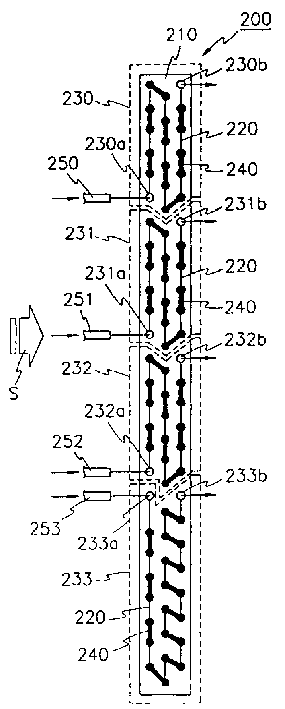

[0016] An embodiment of the present invention will be described in detail below with reference to FIG. 3 . In all the drawings, for simplicity of illustration and description, like reference numerals and symbols are used to denote similar or equivalent parts or parts, and redundant references are omitted.

[0017] As shown in FIG. 3, an air conditioner heat exchanger 200 includes: a plurality of flat blades 210 arranged in parallel at a predetermined interval; and a plurality of heat transfer tubes 220 vertically inserted in the plurality of flat blades 210; and first to second Four coolant passage groups 230, 231, 232, and 233 respectively divide a plurality of coolant pipes 220 into two sides (upper and lower sides), each side has a plurality of return hoses 240, and these hoses and their The respective coolant inlet and outlet components are connected.

[0018] Also, the first to fourth coolant passage groups 230, 231, 232, and 233 include respective coolant passage inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com