Ball bearing producing apparatus and ball bearing producing method

A ball bearing and manufacturing device technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of crown cage deformation, time-consuming maintenance, etc., and achieve the effect of preventing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

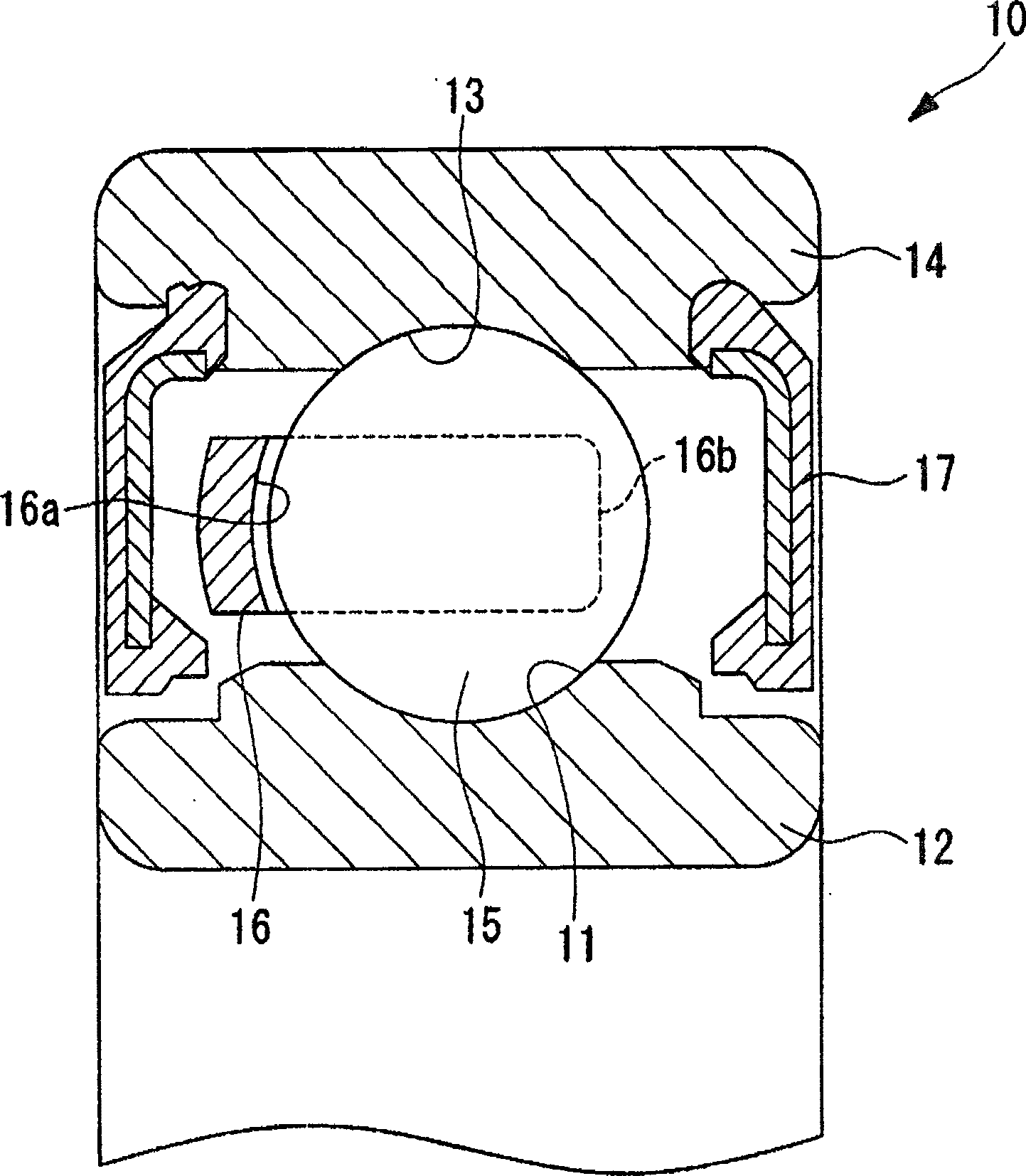

[0046] First, use figure 1 , the structure of the ball bearing 1 manufactured by the ball bearing manufacturing apparatus of this embodiment will be described.

[0047] The ball bearing 10 has a configuration in which a plurality of balls 15 are held by cages 16 at substantially equal intervals between the inner ring 12 and the outer ring 14, and a lubricant is filled between the inner ring 12 and the outer ring 14. In such a state, the axial ends of the inner and outer rings 12 are respectively sealed by the sealing member 17, wherein the inner ring 12 has an inner ring raceway surface 11 on the outer peripheral surface. The outer ring 13 has an outer ring raceway surface 13 on the inner peripheral surface. In the present embodiment, the ball bearing 10 has an outer diameter of about 30 mm to 40 mm and has eight balls 15 incorporated therein.

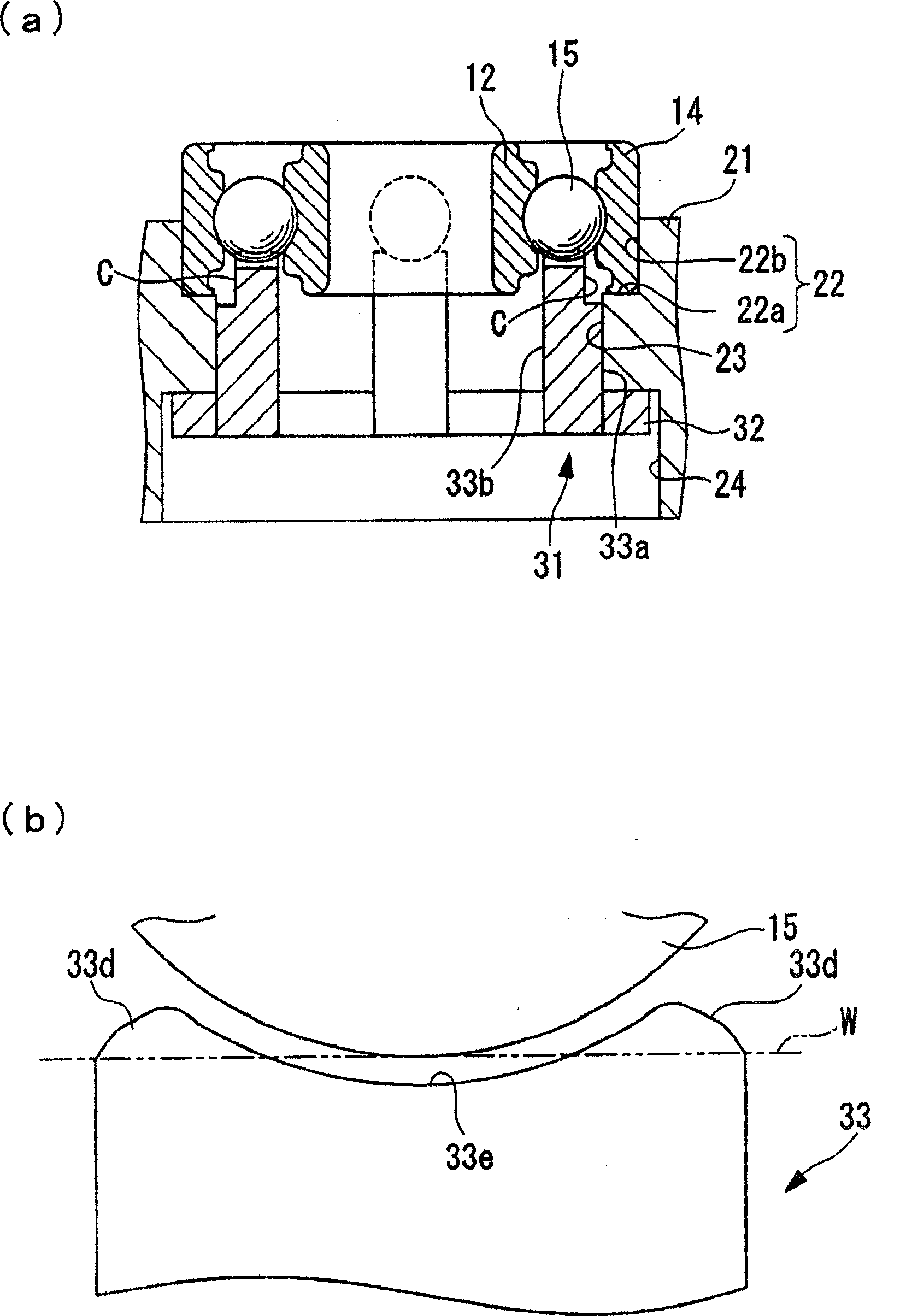

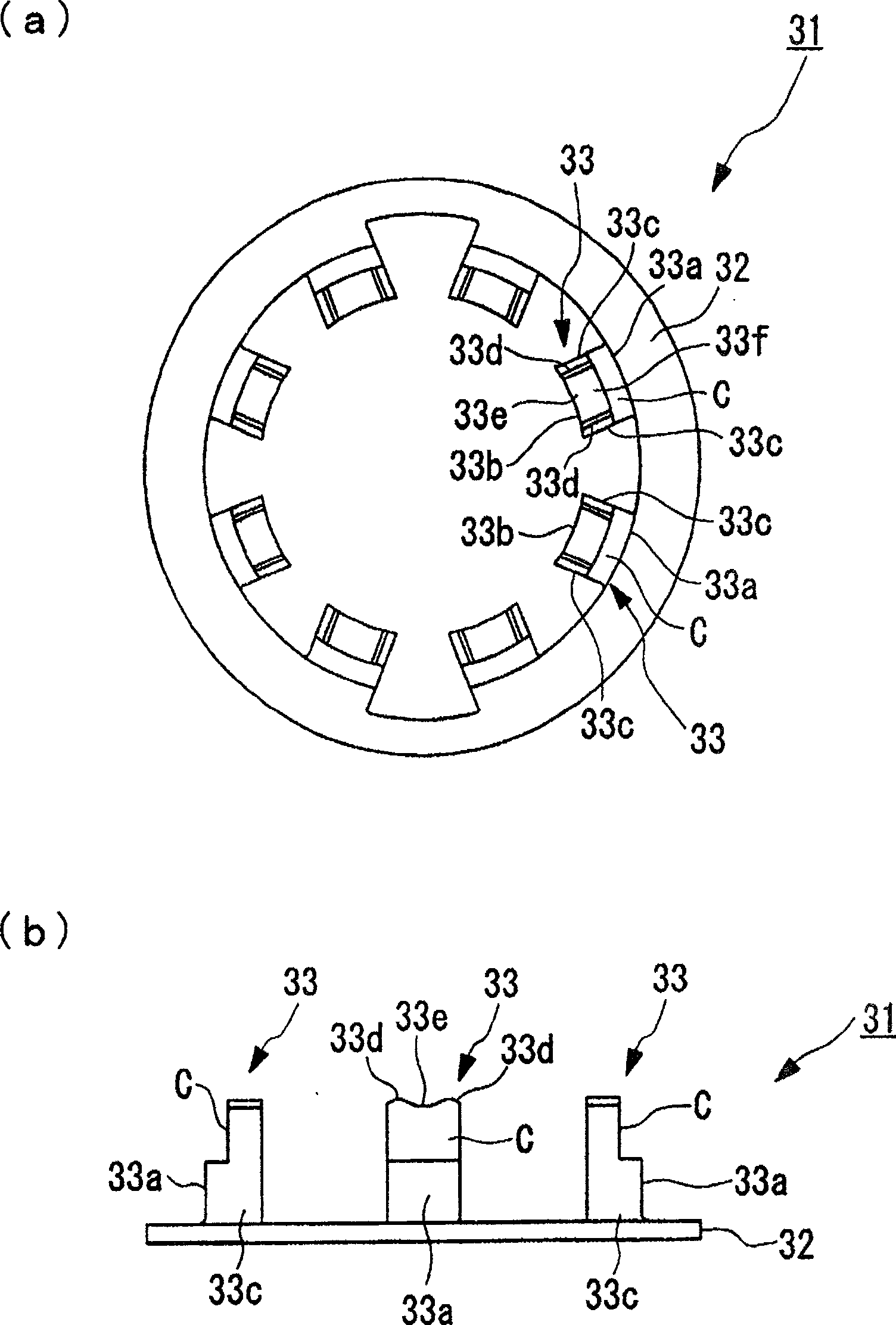

[0048] The retainer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com