Warm-keeping composite cloth material, down and feather product structure with downproofness, and production technique of warm-keeping composite cloth material

A production process and anti-drilling down technology, applied in the field of fabrics, can solve the problems of weak glue spots, easy slipping, poor fluffiness of down, etc., to solve the downhole phenomenon and running down, no need for stitches, and good comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0085] In other embodiments, the first inner fabric cloth 110 and the second outer fabric cloth 230 may not be provided at the same time, that is, the first inner fabric cloth 110 is only provided on the inner side of the first moisture-permeable and windproof elastic PU film 120, or only The outer side of the second moisture-permeable and windproof elastic PU film 220 is provided with a second outer fabric cloth 230 .

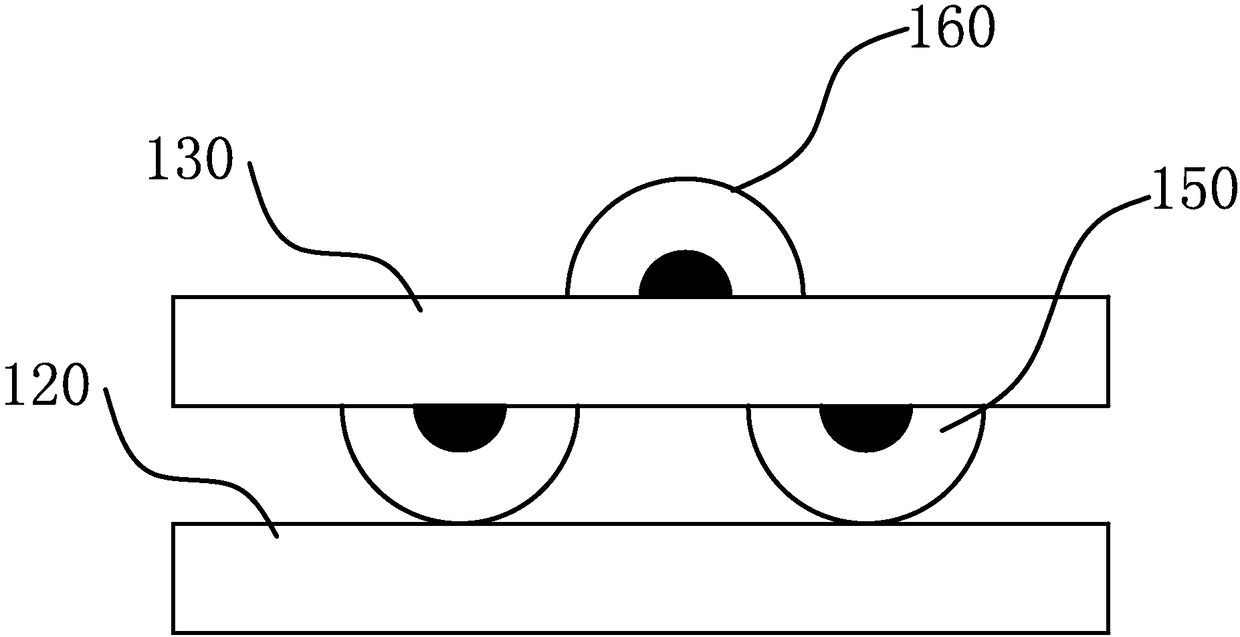

[0086] Please refer to Figure 10 , the edge banding structure 300 has a strip-shaped elastic base fabric 310, and the inner and outer sides of the elastic base fabric 310 are respectively provided with double-point glue-coating structures 320 and 330, and the double-point glue-coating structure 320 is used for the second layer of the inner composite fabric 100. An outer fabric cloth 130 is bonded to a side away from the first moisture-permeable and windproof elastic PU film 120, and the double-point glue coating structure 330 is used to bond with the second i...

no. 1 example

[0093] Please refer to Figure 14 , the first embodiment of the production process of the thermal composite cloth provided by the present invention comprises the following steps:

[0094] Step S1: Making the outer composite fabric 200.

[0095] Step S2: Fabricate the inner composite fabric 100.

[0096] Step S3: Set a double-point glued structure 160 on the side of the first outer fabric fabric 130 of the inner composite fabric 100 away from the first moisture-permeable and windproof elastic PU film 120 .

[0097] The setup process of the double-point gluing structure is as follows:

[0098] Step S151: preparing a base slurry, blending polyacrylate emulsion and water and stirring evenly, adding an appropriate thickener and stirring evenly, and preparing a base slurry with a certain viscosity.

[0099] Step S152: Prepare hot sol powder.

[0100] Step S153: performing a paste coating process on the cloth with a primer to form a plurality of paste spots, which constitute the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com