Insert separating stainless steel bowl device

A separation device, stainless steel technology, applied in the direction of household cleaning devices, tableware washing machines/rinsing machines, cleaning equipment, etc., can solve the problems of high cost and low work efficiency, achieve high work efficiency, reduce labor costs, and reliable structure practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

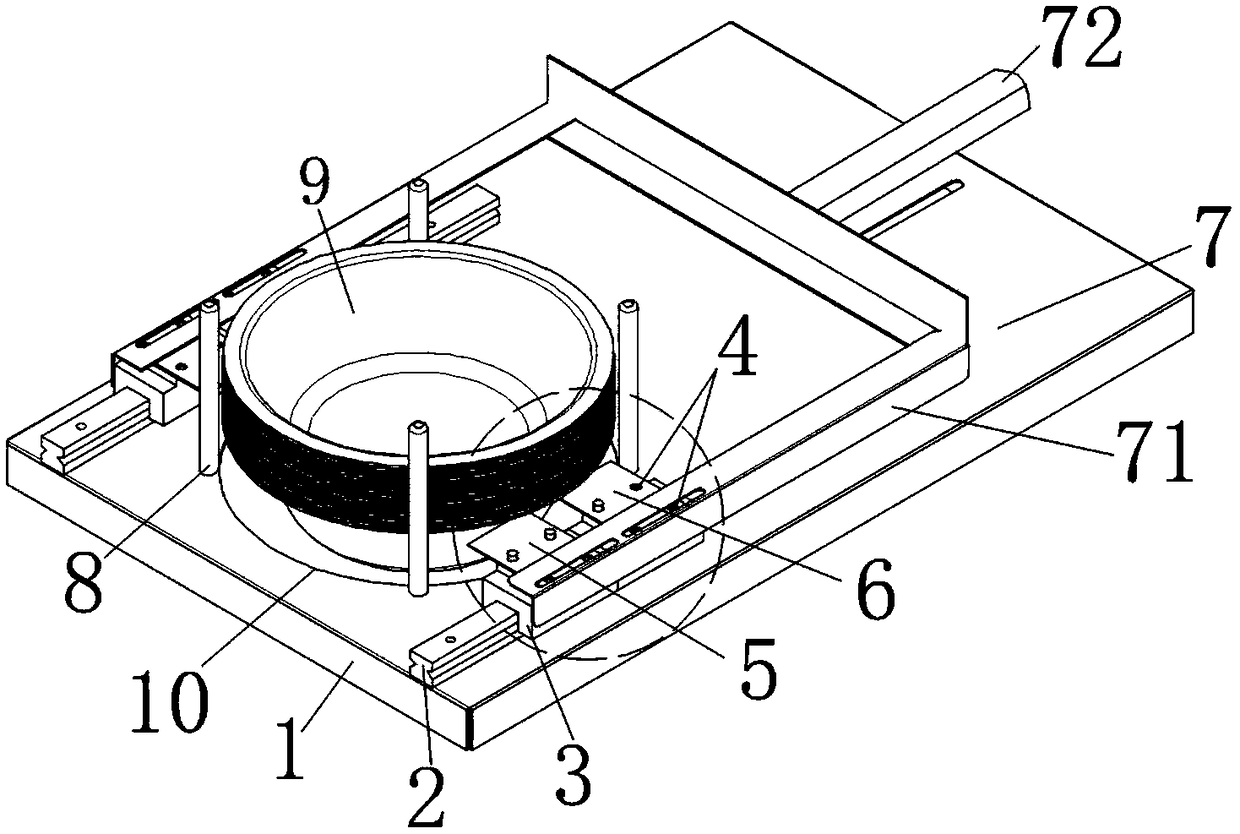

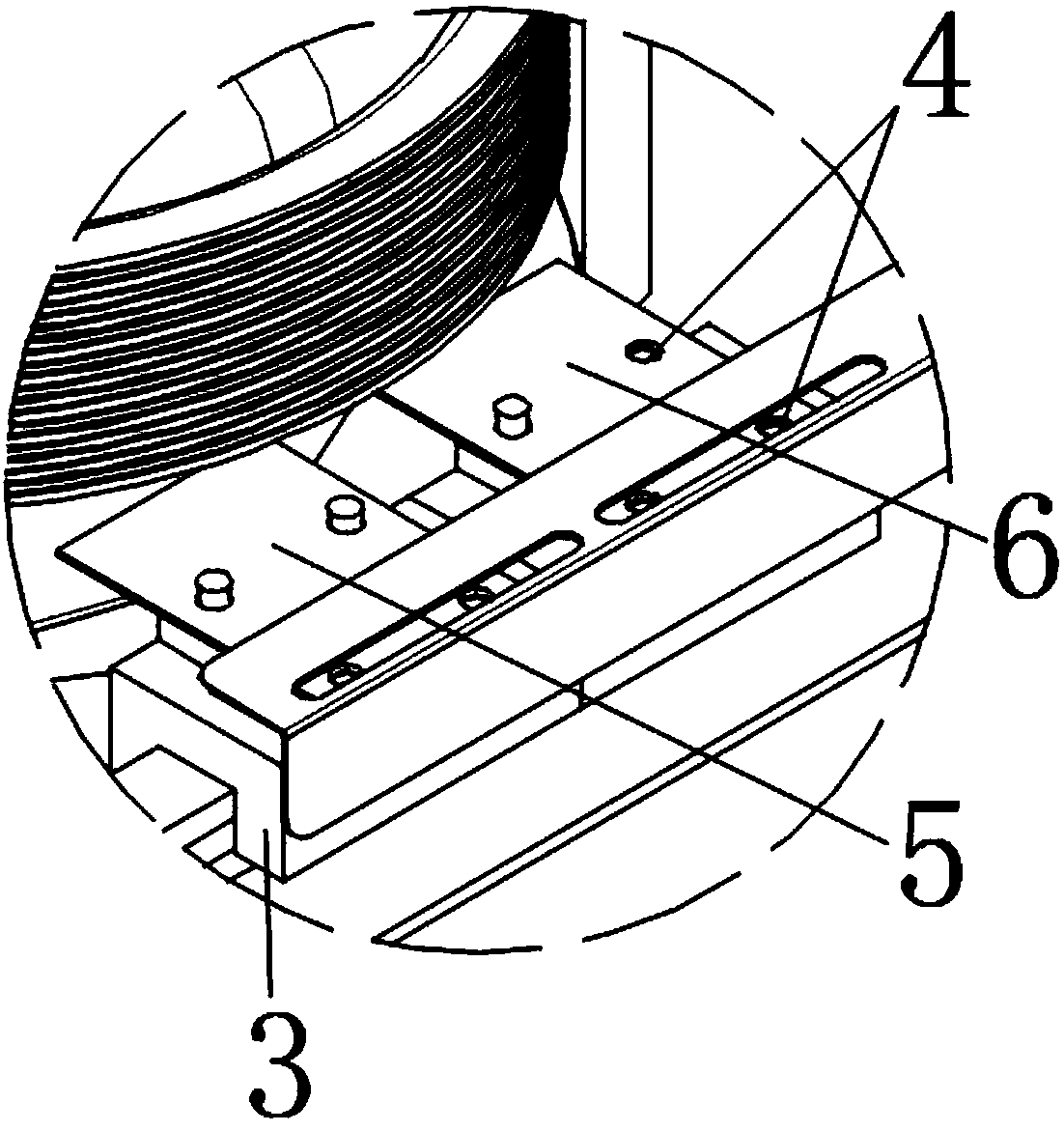

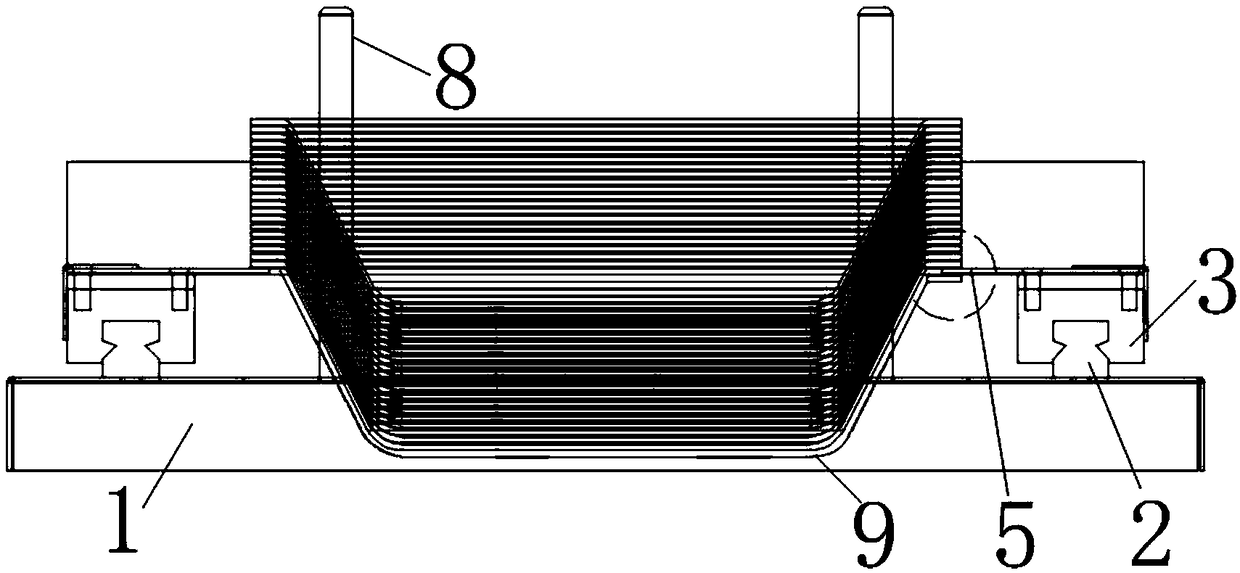

[0024] Please refer to figure 1 , figure 2 , image 3 , a stainless steel bowl separation device with inserts, including a bottom plate 1, a slide rail 2 is fixed on the left and right sides of the upper end surface of the bottom plate 1, and there are different numbers of openings on the bottom plate 1 between the slide rails 2 on the left and right sides. Less than one opening 10 (opening is a plurality of schematic diagrams see Figure 8 ), the edge area of each opening 10 is provided with a stainless steel bowl limiting device 8, the stainless steel bowl limiting device 8 is a plurality of positioning columns 8 evenly arranged in the edge area of the opening 10, and the stainless steel bowl is placed in the middle of the limiting device 8; Each slide rail 2 is covered with a slider 3 that can slide on the slide rail. The slider 3 is fixed with a high-position in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com