Half-deep-cone thickener

A deep-cone thickener and thickener technology, which is applied in the settling tank, the feeding/discharging device of the settling tank, chemical instruments and methods, etc. High cost, inability to meet the requirements of outputting high-concentration products, etc., to achieve the effect of improving work efficiency, increasing material concentration, and increasing underflow concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

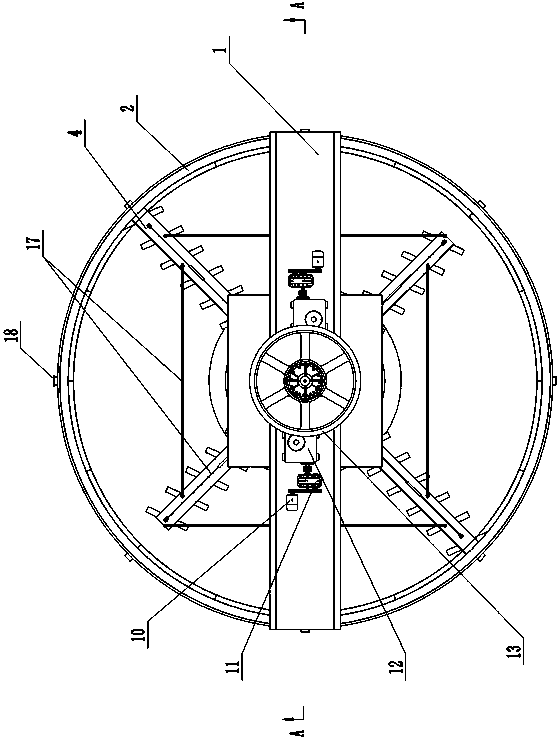

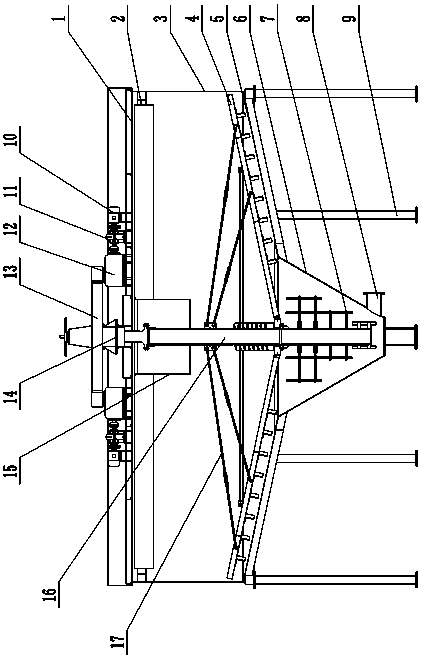

[0017] see figure 1 , figure 2 , the present invention is a semi-deep cone thickener, which has a thickener bracket 9, a tank body is installed on the thickener bracket, a crossbeam 1 is arranged on the upper part of the tank body along the diameter direction, and a circle of overflow grooves is arranged on the upper part of the tank body along the circumferential direction 2. A number of overflow outlets 18 are provided on the overflow tank, and a feed cylinder 15 is provided at the center of the pool body. The pool body is composed of an upper cylinder 3 and a lower double-cone structure. The lower double-cone structure It is composed of an inverted large cone 5 and an inverted small cone 6, wherein the large cone is located above the small cone, and the angle between the conical surface of the large cone and the horizontal plane is 8-12°. The inclination angle between the conical surface of the cone and the horizontal plane is 50-60°, the preferred angle is 55°, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com