An energy-saving and environment-friendly dust suppression and dedusting equipment

A dust removal equipment, energy saving and environmental protection technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as environmental pollution and waste of water resources, and achieve the effects of protecting the environment, saving energy and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

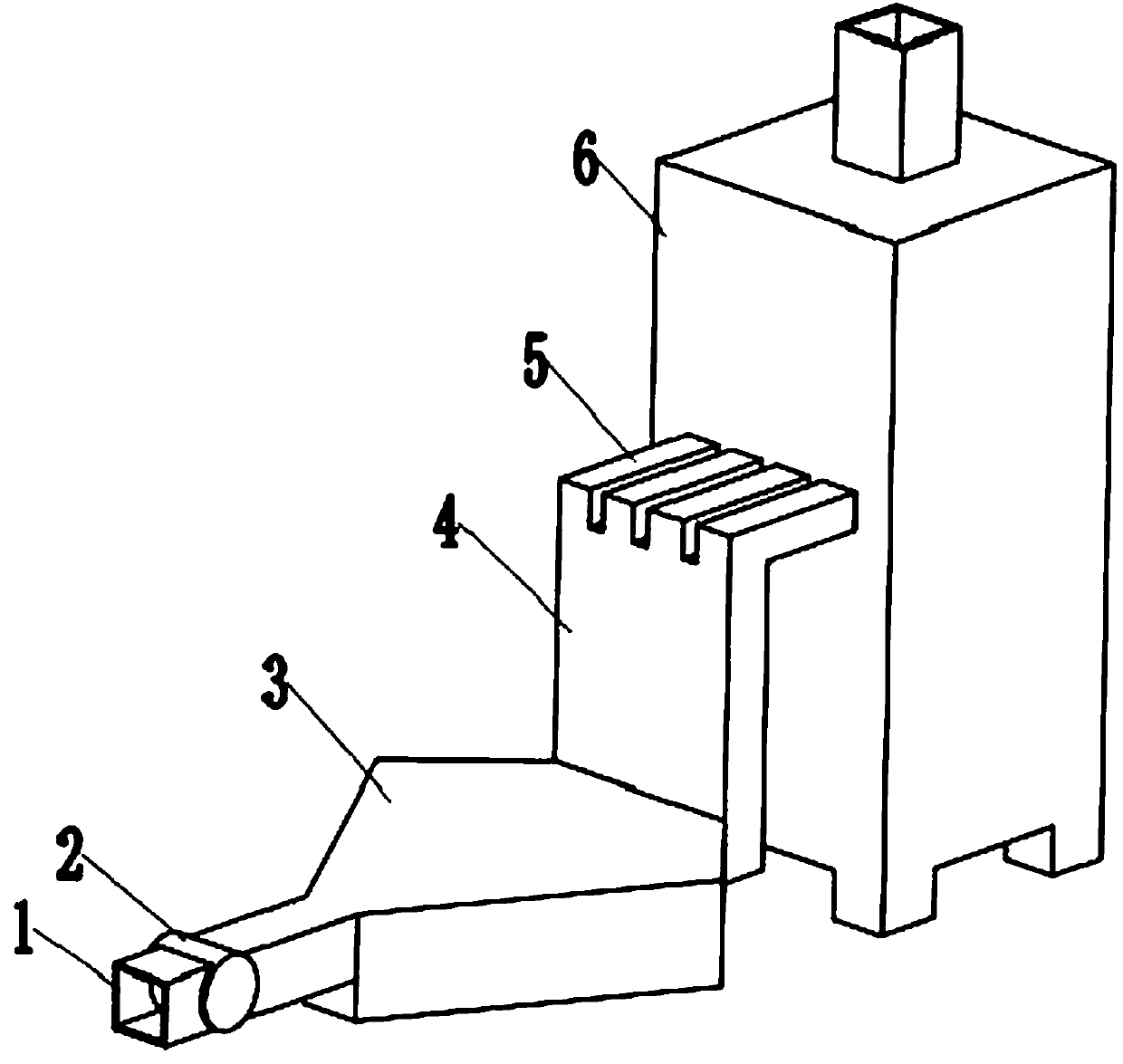

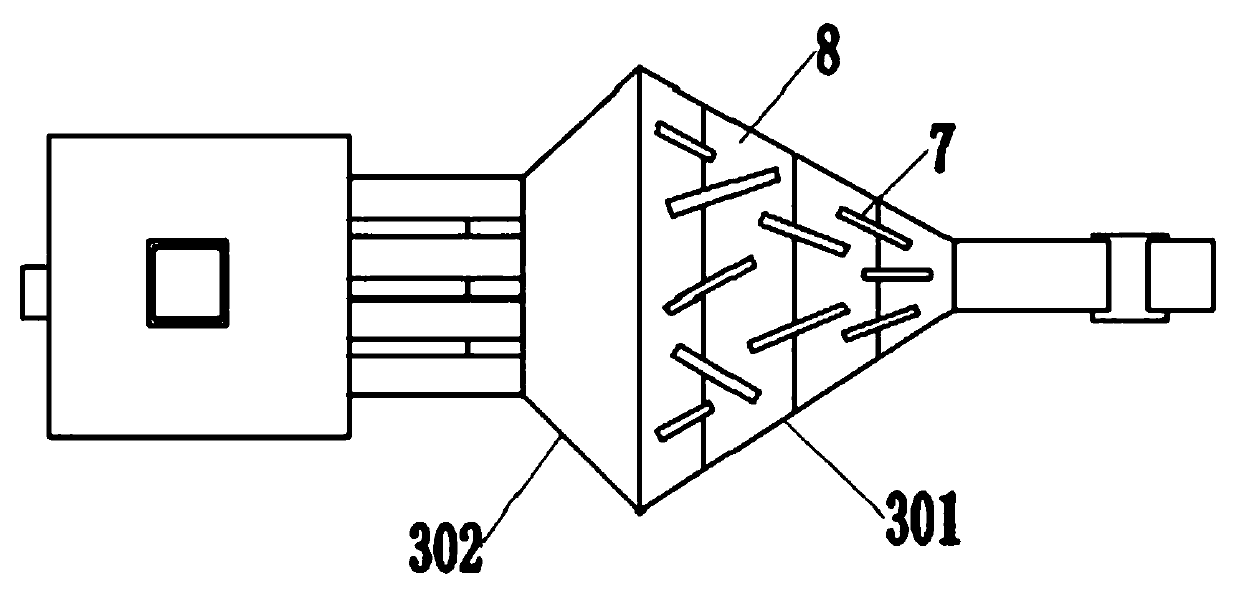

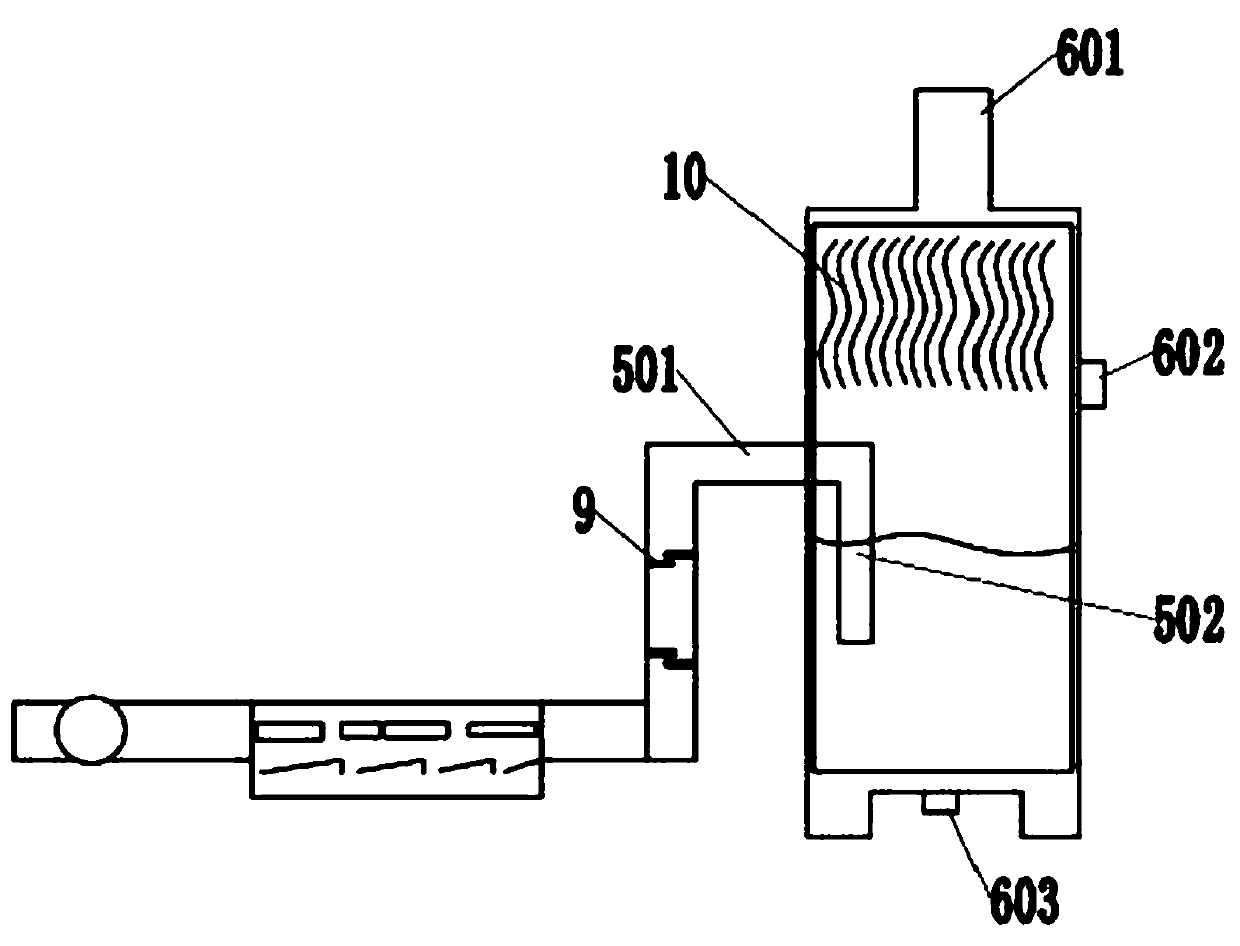

[0026] see Figure 1-4 , the invention provides a technical solution: an energy-saving and environment-friendly dust reduction and dedusting equipment, including a dust inlet pipe 1, a first-level dust-reduction chamber 3, a second-level dust-fall chamber 4, an air guide pipe 5, and a scrubbing chamber 6. The dust inlet pipe 1 and The first-level dust-reducing chamber 3 is connected, and the first-level dust-reducing chamber 3 is divided into an air distribution chamber 301 and an air receiving chamber 302. , the lower layer of the air distribution chamber 301 is provided with a dust-reducing plate 8, the secondary dust-fall chamber 4 communicates with the air-receiving chamber 302, and the air-guiding pipe 5 communicates with the secondary dust-fall chamber 4 and the scrubbing chamber 6 respectively. A dehydration plate 10 is provided in the scrubbing chamber 6, an exhaust pipe 601 is provided at the upper end of the scrubbing chamber 6, a liquid discharge pipe 603 is provide...

Embodiment 2

[0029] An energy-saving and environment-friendly dust reduction and dedusting equipment, comprising a dust inlet pipeline 1, a first-level dust-fall chamber 3, a second-level dust-fall chamber 4, an air guide pipe 5, and a scrubbing chamber 6. The dust inlet pipeline 1 communicates with the first-level dust-fall chamber 3. The first-level dust-suppression chamber 3 is divided into an air distribution chamber 301 and an air collection chamber 302. The air distribution chamber 301 communicates with the air collection chamber 302. The upper layer of the air distribution chamber 301 is provided with a splitter plate 7. The lower floor is provided with a dust-reducing plate 8, the secondary dust-fall chamber 4 communicates with the air receiving chamber 302, and the air guide pipe 5 communicates with the secondary dust-fall chamber 4 and the air washing chamber 6 respectively, and the air washing chamber 6 is provided with a dehydration Plate 10, an exhaust pipe 601 is provided at t...

Embodiment 3

[0031] An energy-saving and environment-friendly dust reduction and dedusting equipment, comprising a dust inlet pipeline 1, a first-level dust-fall chamber 3, a second-level dust-fall chamber 4, an air guide pipe 5, and a scrubbing chamber 6. The dust inlet pipeline 1 communicates with the first-level dust-fall chamber 3. The first-level dust-suppression chamber 3 is divided into an air distribution chamber 301 and an air collection chamber 302. The air distribution chamber 301 communicates with the air collection chamber 302. The upper layer of the air distribution chamber 301 is provided with a splitter plate 7. The lower floor is provided with a dust-reducing plate 8, the secondary dust-fall chamber 4 communicates with the air receiving chamber 302, and the air guide pipe 5 communicates with the secondary dust-fall chamber 4 and the air washing chamber 6 respectively, and the air washing chamber 6 is provided with a dehydration Plate 10, an exhaust pipe 601 is provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com