Automatic curing system of cast-in-place concrete

A curing system and concrete technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of insufficient concrete curing, waste of water resources, and high labor costs, so as to achieve considerable economic benefits, save labor, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

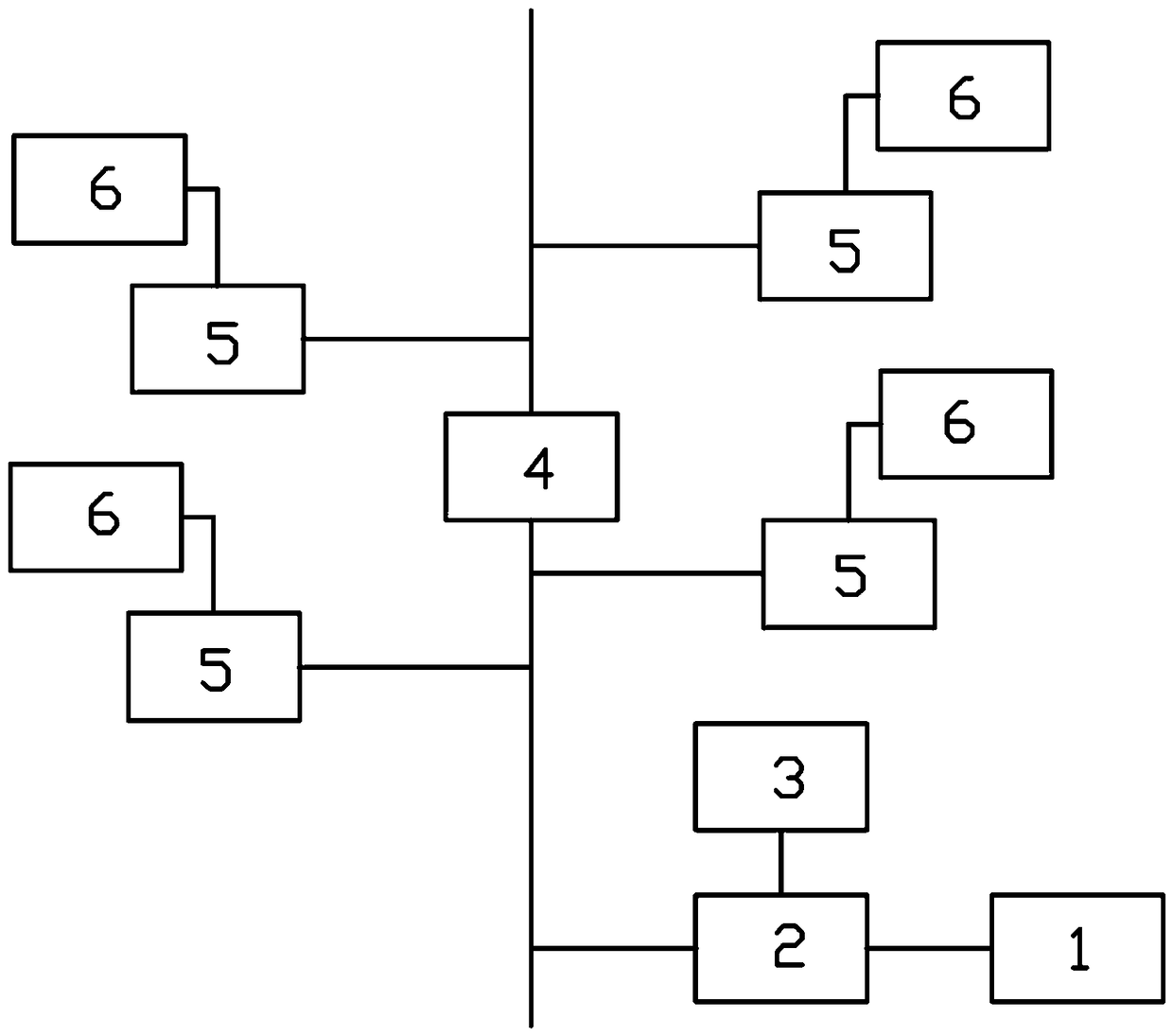

[0012] Such as figure 1 and figure 2 As shown, the specific embodiment of the present invention is: the present invention includes a pressure pump 2 connected to an external reservoir 1, an interval timer 3 electrically connected to the pressure pump 2, and an output port connected to the pressure pump 2 The main pipeline 4 and several branch pipelines 5 that are connected with the main pipeline 4 and arranged in sequence on each floor, each outlet of the branch pipeline 5 is provided with a sprinkler module 6 .

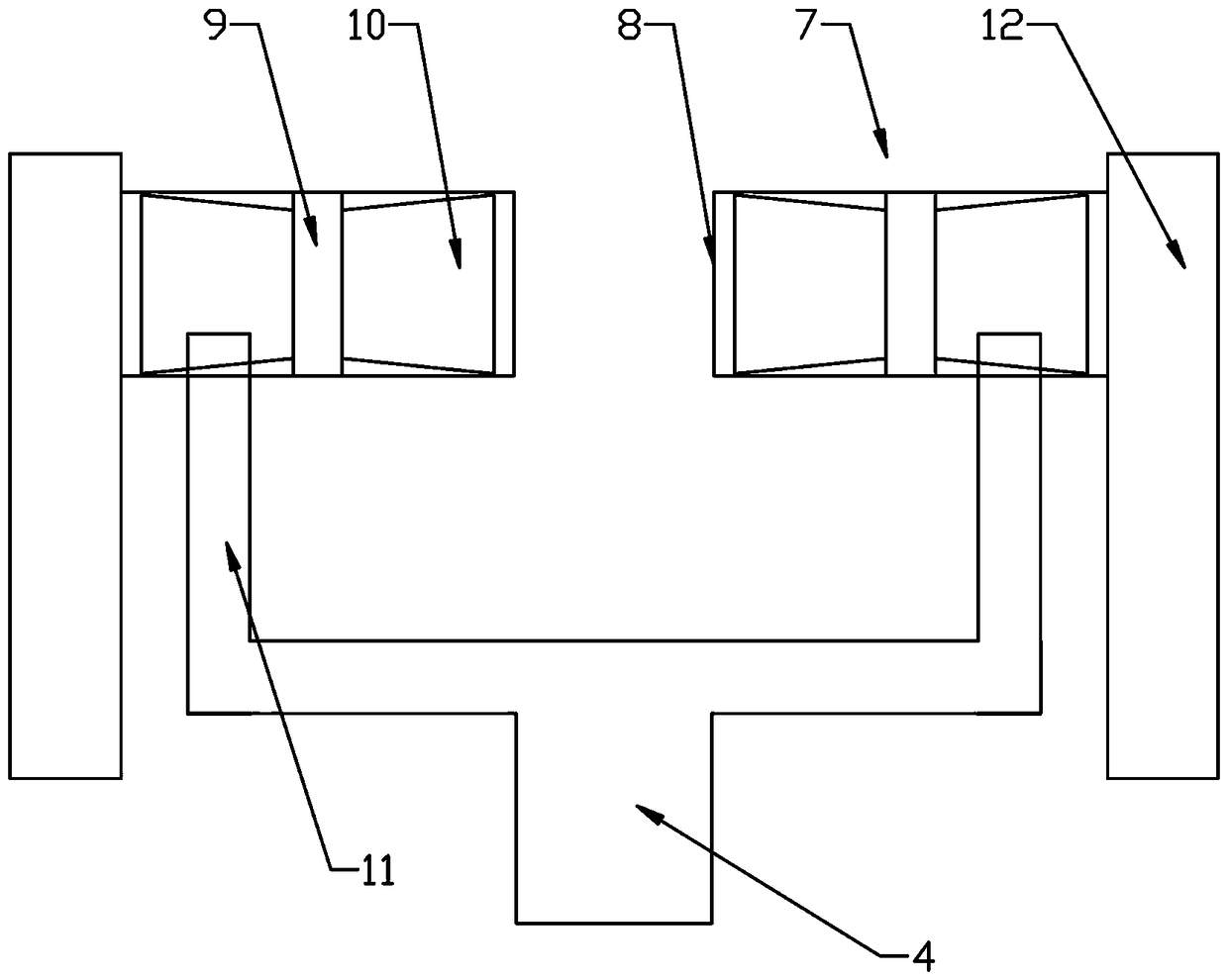

[0013] In this specific embodiment, the spray head module 6 includes two spray heads 7 arranged opposite to each other. The spray heads 7 include a rectangular housing 8 and a rotating shaft 9 vertically arranged in the middle of the rectangular housing 8. The rotating shaft 9 A wind impeller 10 is arranged coaxially, and the wind impeller 10 is arranged inside the rectangular casing 8. Two branch nozzles 11 are connected to the end of the branch pipe 5, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com