A high-vacuum rapid realization device for die-casting molds

A high-vacuum, die-casting mold technology, applied in the field of casting, can solve the problems of low gas content, high mechanical properties, and low vacuum degree of castings, and achieve the effects of high mechanical properties, low gas content, and reduced air entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

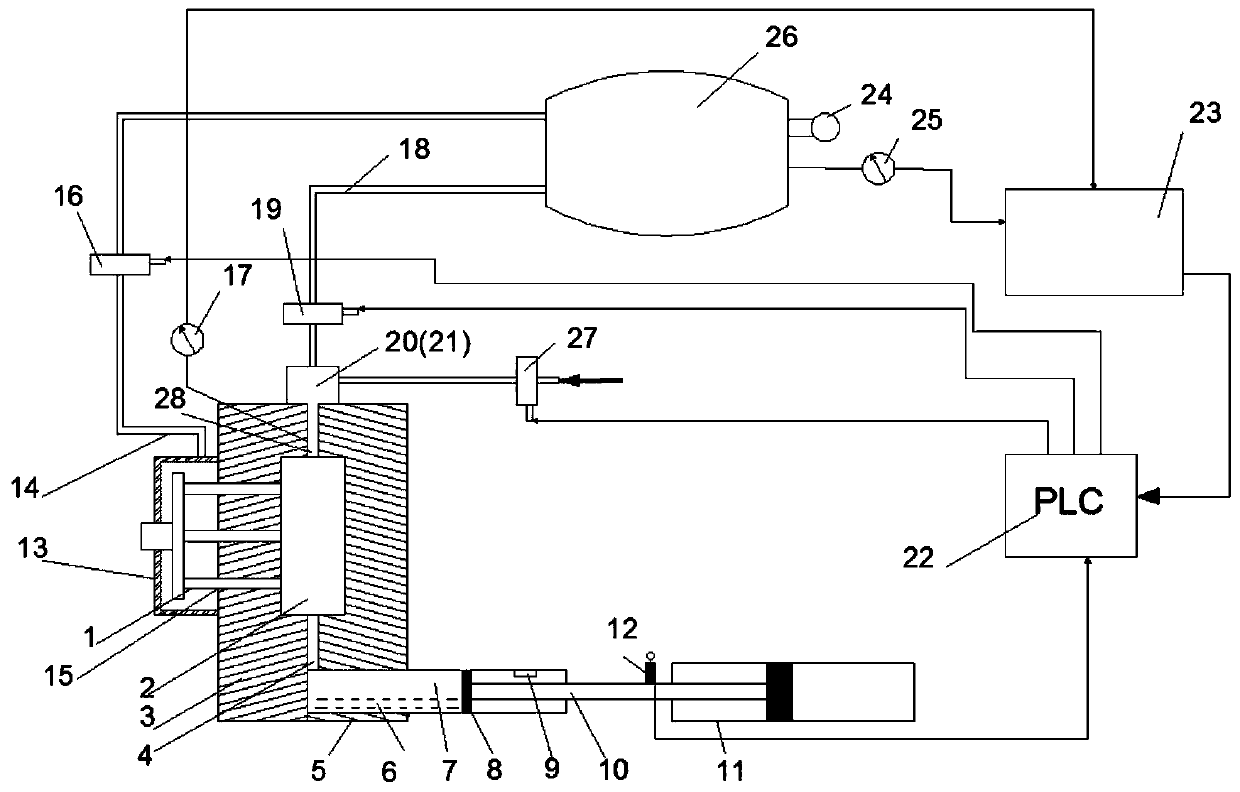

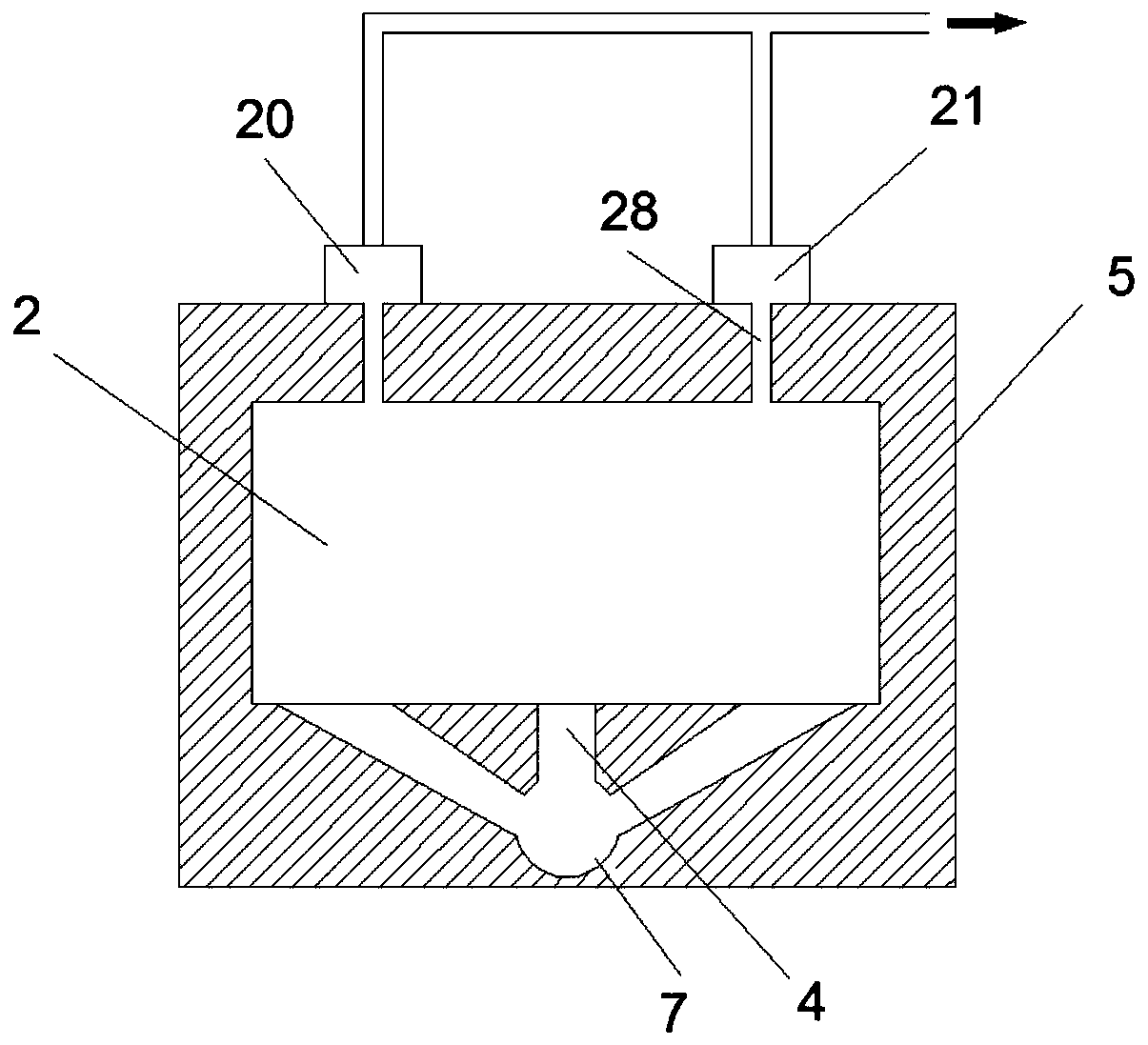

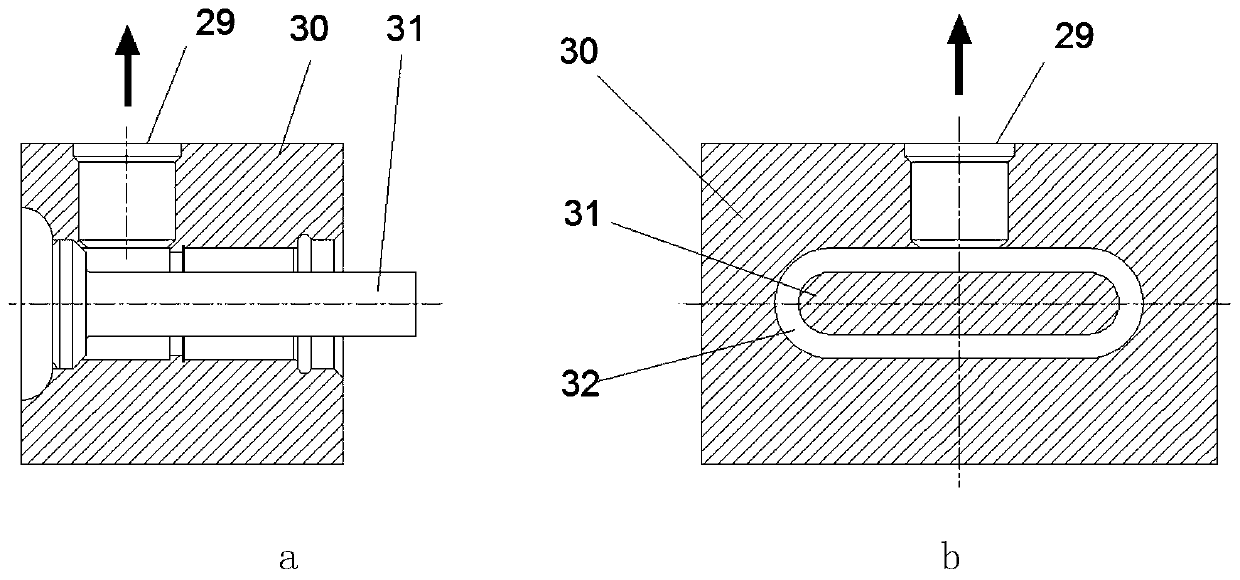

[0047] In this embodiment, according to the method for fast realization of high vacuum in die-casting molds of the present invention, YL104-based aluminum alloys (the impurity content in the alloy is controlled to be Fe<0.20%, Cu<0.05%) are die-casted on a 4000kN horizontal cold chamber die-casting machine.

[0048] First of all, make a good seal on the die-casting mold. The specific sealing method can adopt the sealing structure of the existing high-vacuum pressure casting die-casting mold. The vacuum valve structure adopts a hydraulic drive type with a large exhaust area. Two vacuum valves are connected in parallel, and the vacuum valves are connected in parallel. The total exhaust area of the casting is equal to 30% of the cross-sectional area of the casting cavity; then the YL104 alloy is melted, refined, and an appropriate amount of modifier and refiner is added to control the appropriate temperature for pouring, and the mold is preheated to 150 ~200°C, pour an appropr...

Embodiment 2

[0051] In this embodiment, according to the method for quickly realizing the high vacuum of the die-casting mold of the present invention, the YL104-based alloy (the impurity content in the alloy is controlled Fe<0.20%, Cu<0.05%) is die-casted on an 8000kN horizontal cold chamber die-casting machine.

[0052] First of all, make a good seal on the die-casting mold. The specific sealing method can adopt the sealing structure of the existing high-vacuum pressure casting die-casting mold. The vacuum valve structure adopts a hydraulic drive type with a large exhaust area. Three vacuum valves are connected in parallel, and the vacuum valves are connected in parallel. The total exhaust area of the casting is equal to 40% of the cross-sectional area of the casting cavity; then the YL104 alloy is melted, refined, and an appropriate amount of modifier and refiner is added to control the appropriate temperature for pouring, while the mold is preheated to 150- At 200°C, pour an appropr...

Embodiment 3

[0055] In this embodiment, according to the method for fast realization of high vacuum of the die-casting mold of the present invention, the YL104-based alloy (the impurity content in the alloy is controlled Fe<0.20%, Cu<0.05%) is die-casted on a 16000kN horizontal cold chamber die-casting machine.

[0056] First of all, make a good seal on the die-casting mold. The specific sealing method can adopt the sealing structure of the existing high-vacuum pressure casting die-casting mold. The vacuum valve structure adopts a hydraulic drive type with a large exhaust area, and 4 vacuum valves are connected in parallel. Parallel vacuum valves The total exhaust area of the casting is equal to 35% of the cross-sectional area of the casting cavity; then the YL104 alloy is melted, refined, and an appropriate amount of modifier and refiner is added to control the appropriate temperature for pouring, while the mold is preheated to 150 ~200°C, pour an appropriate amount of molten metal int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com