Successive type robot oriented to large loads

A robotic and continuous technology, applied in the field of robotics, can solve problems that are difficult to meet the use requirements, and achieve the effects of large bearing capacity, improved force characteristics, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

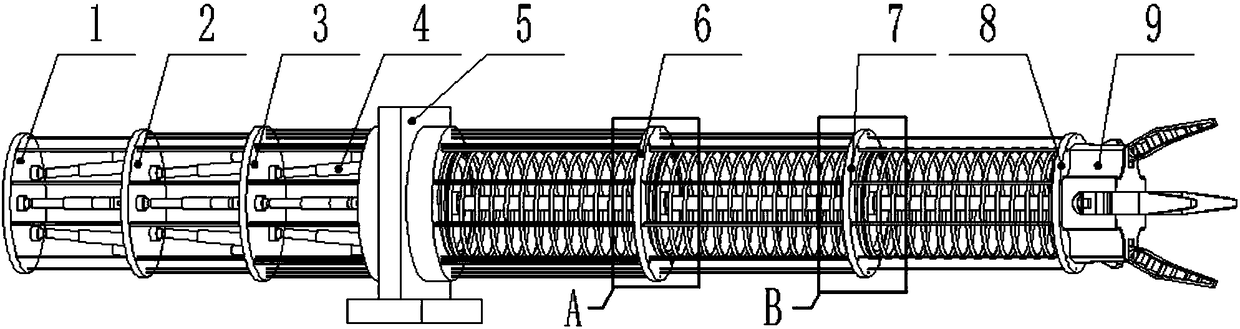

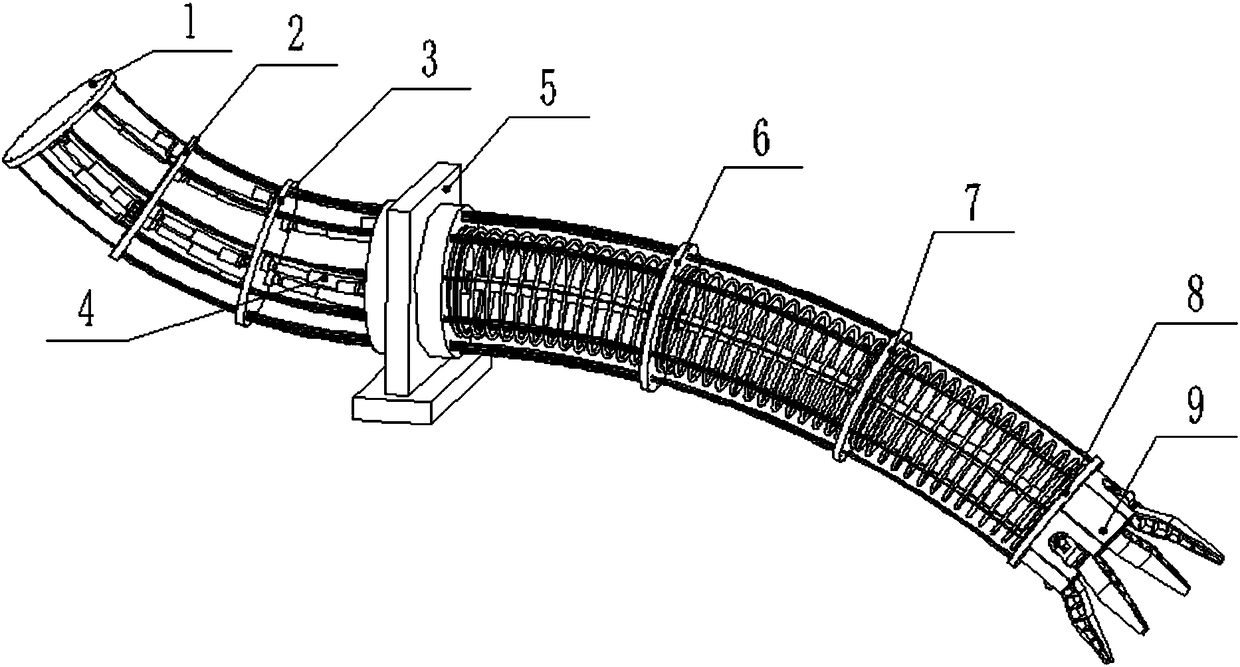

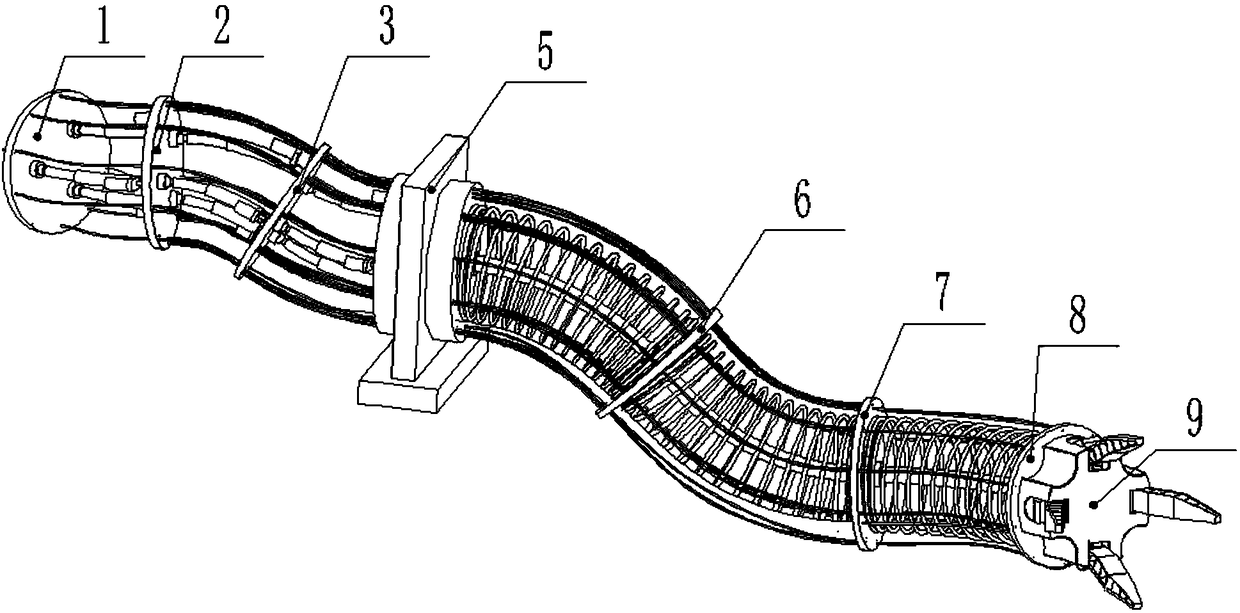

[0019] exist figure 1 , figure 2 and image 3 In the three-dimensional schematic diagram of a continuous robot facing a large load shown in the figure, the main body of the frame 5 is an inverted "T"-shaped structure, and a cylindrical boss is arranged on both sides of the frame, and two through-holes are processed on the boss. The through hole of the boss, the center of the cylindrical boss on one side of the frame is provided with a central boss, which is provided with an inner screw hole, which is threaded with one end of the elastic body 13, and the other end of the elastic body is connected with the second middle. The screw hole thread connection that establishes in the center boss of connecting plate 6 one sides, is provided with coaxial ring-shaped boss on the periphery of frame center boss, this ring-shaped boss links to each other with an end of spring 14, and the The other end is connected with the annular boss of the second intermediate connection plate. The scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com