Anti-vibration and vibration-reduction device for core mold

A vibration damping device and anti-vibration technology, which is applied in the direction of ceramic molding cores, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of low production efficiency, easy ground vibration, and noise generation, and achieve convenient processing and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

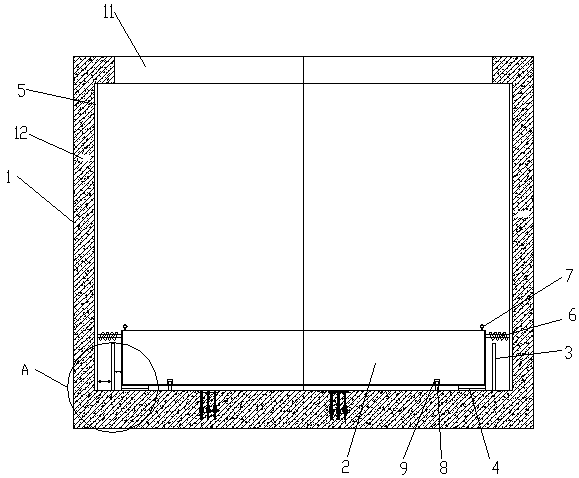

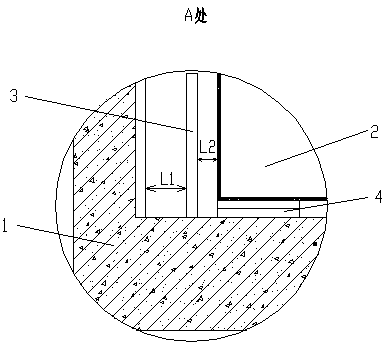

[0016] The present invention as Figure 1-2 , including a box body 1 with a top opening 11 and a base 2, the two sides of the box body are respectively provided with inlets 12 (for placing power cords, etc.), and the bottom and top surface of the box body is provided with a rectangular frame body 3, A distance one L1 is set between the frame body and the inner wall of the box body, the base is located in the frame body, a distance two L2 is set between the frame body and the base, and the bottom surface of the base is provided with a vertical setting The shock absorber-4;

[0017] The inner wall of the box body is provided with sound-absorbing cotton 5 .

[0018] In the work of the present invention, the mandrel is placed on the base, and since the base is arranged in the box body, a shock absorber is arranged on the bottom surface of the base to play a reliable vibration damping effect; at the same time, a sound-absorbing Cotton plays a role of sound absorption and reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com