Timely temperature response open mill roller device

A technology of temperature response and open mill, applied in the field of open mill, can solve the problems of reducing heat exchange efficiency, unfavorable energy consumption, improvement, etc., and achieve the effect of increasing heat exchange rate and improving effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

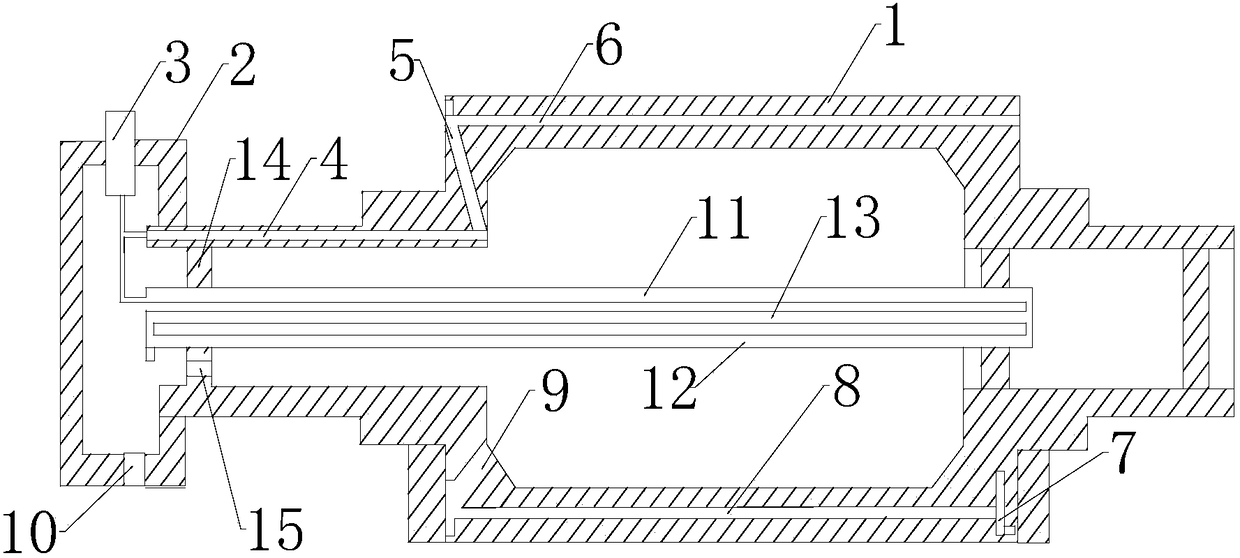

[0021] like figure 1 As shown, a mill roller device with timely temperature response includes a roller body 1 with an inner cavity, the front end of the roller body 1 is connected with a fixed rotary joint 2, and the end of the roller body 1 is connected with a The connection flange, the fixed rotary joint 2 is a cavity structure, the fixed rotary joint 2 is connected with the first flow channel 3 for the working medium to enter, and the outer wall of the front end side of the roller body 1 is opened along the long axis direction and the second flow channel. The second flow channel 4 communicated with the flow channel 3, the outer wall of the front end of the roller shell 1 is provided with the third flow channel 5 communicating with the second flow along the radial direction, and the outer wall of one side of the roller shell 1 is along the length A fourth flow channel 6 communicating with the third flow channel 5 is opened in the axial direction, and a fifth flow channel 7 c...

Embodiment 2

[0024] Similar to Embodiment 1, a secondary cooling device is also provided in the inner cavity of the roller shell 1, and the secondary cooling device includes an inflow channel 11 for the working medium to enter and an outflow channel 12 for the output of the working medium, and the inflow channel 11 is connected with the outflow channel 12 and the inflow channel 11 and the outflow channel 12 are arranged in parallel. 2 cavity structure. The function of installing the secondary cooling device is that the working medium entering from the first flow channel 3 can circulate in the secondary cooling device, and during its circulation, it will exchange heat with the working medium flowing through the outer wall channel of the roller body 1 Heat exchange is performed, thereby preventing heat exchange between the working medium that newly enters the outer wall of the roller body 1 and the heat-exchanged working medium that has entered the cavity of the roller body 1 , thereby impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com