A horizontal supercritical fluid foaming equipment

A technology of supercritical fluid and foaming equipment, applied in the field of polymer material processing, can solve the problems of inconvenient operation of the supercritical fluid reactor, safety protection device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 tank body sealing process

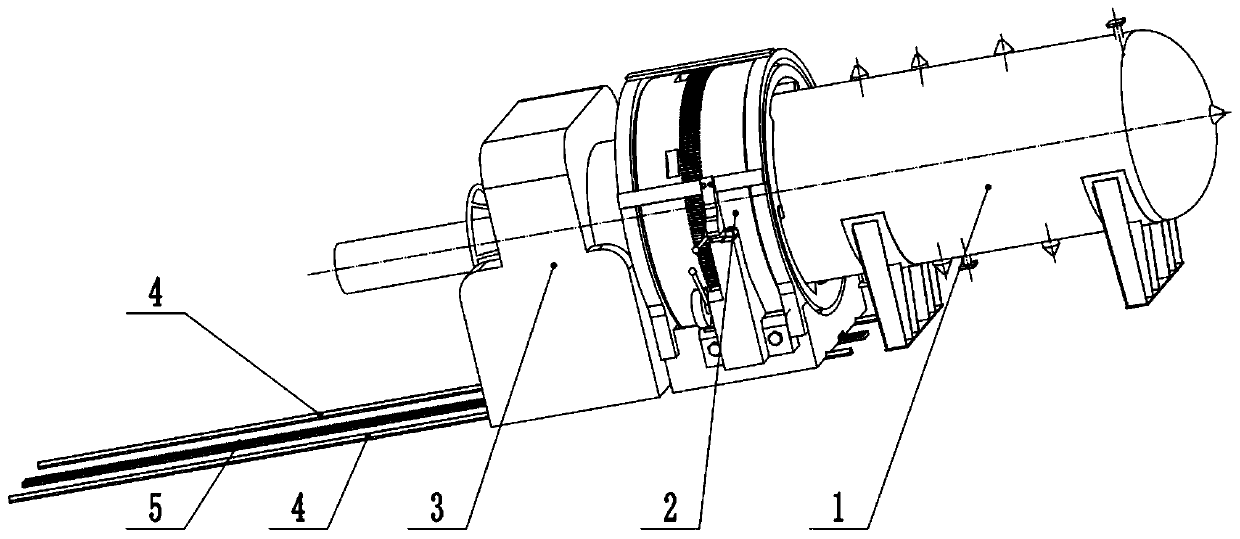

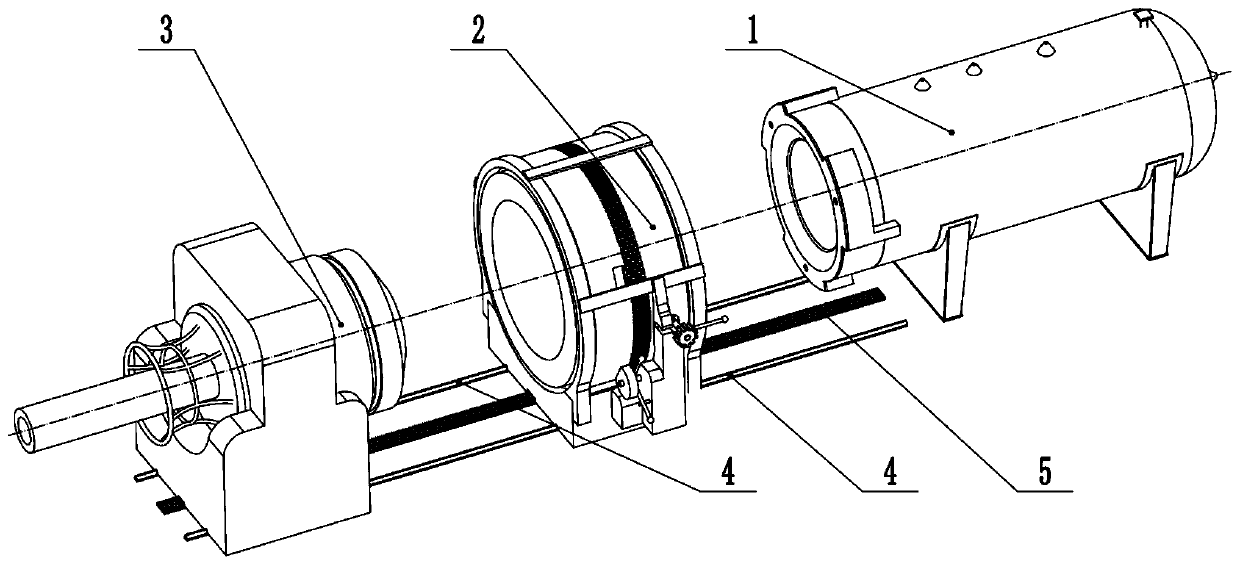

[0029] Refer to attached figure 1 to attach Figure 8 , when the tank assembly (1), clamp assembly (2), and compression assembly (3) are in a non-combined state, put the polymer to be processed into the inner cylinder (15), and then pass through the clamp The rotation control assembly (43) in the assembly (2) rotates the clamp (45), and the steps are as follows:

[0030] 1) Rotate the limit handle (64) until the handle is in contact with the limit pin B (78). At this time, the gap of the notch disc (79) of the limit handle (64) is facing the clamp (45), without affecting the clamp (45) turn;

[0031] 2) Turn the gear handle (62) installed on the rotating shaft (63) around the axis A (74), so that the gear handle (62) is turned into the shaft limit groove (76) of the base B (61), at this time The gear of the gear handle (62) meshes with the rotating teeth (86) on the clamp (45), and the rotation of the gear handle (62) can mak...

Embodiment 2

[0036] Embodiment 2 supercritical fluid processing

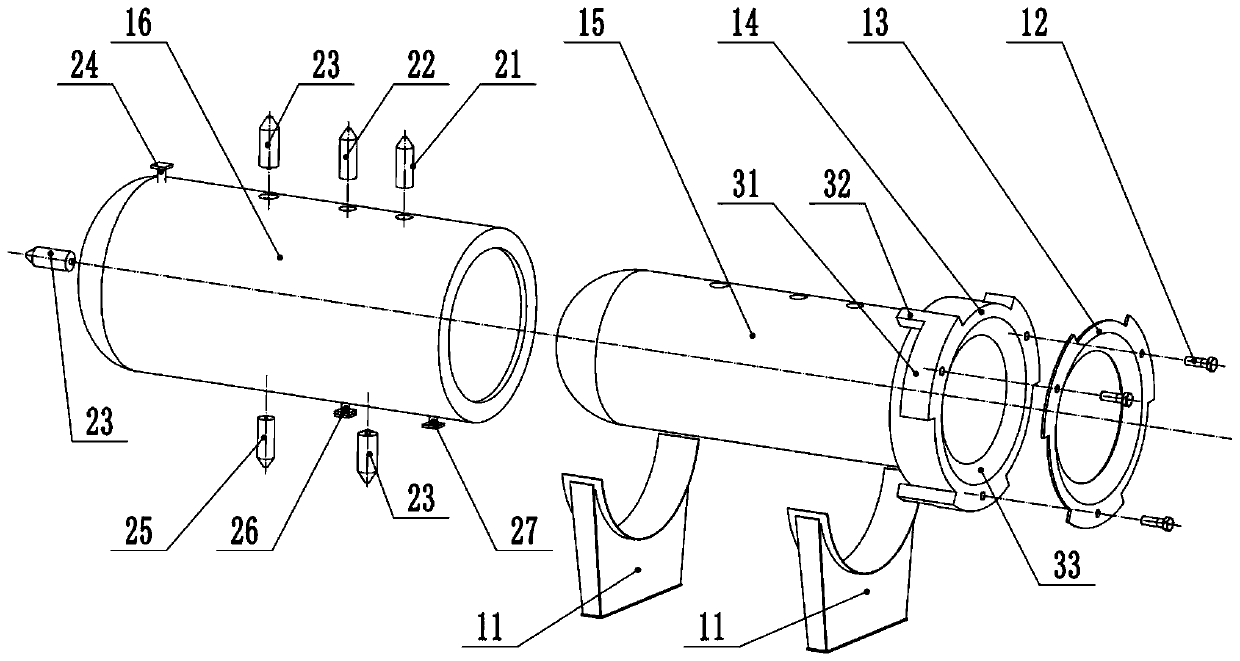

[0037] Refer to attached figure 1 , attached image 3 , attached Figure 7 And attached Figure 8 , preparatory steps for supercritical fluid processing:

[0038] 1) Heating medium oil injection, emptying and cleaning

[0039] Fill the oil from the heat transfer oil inlet (27) into the hollow space formed by the tank locking end (14), the inner cylinder (15) and the jacket (16), and the excess oil will be discharged from the heat transfer oil outlet (24) Recycling, when the oil contains impurities and needs to be discharged from the tank, the oil can be completely emptied by connecting an external conduit at the drain outlet (26).

[0040] 2) Installation and connection of tank monitoring, safety devices and external media

[0041] Install and connect the safety valve, pressure gauge and temperature sensor at the safety valve interface (21), pressure gauge interface (22) and temperature sensor connecting pipe extension...

Embodiment 3

[0043] Embodiment 3 tank opening process

[0044] Refer to attached figure 2 to attach Figure 8 , the tank opening process steps are:

[0045] 1) Rotate the circular turret (96) to unscrew the T-shaped compression block (93) of the compression assembly (3) from the clamp (45), and then place the compression assembly (3) along the track (4) as a whole Move outward until the tapered guide rod (91) is out of contact with the clip (45);

[0046] 2) Rotate the limit handle (64) until the handle is in contact with the limit pin B (78). At this time, the gap of the notch disc (79) of the limit handle (64) is facing the clamp (45), and the clamp (45) In the unlocked state, then the gear of the gear handle (62) is engaged with the rotating teeth (86) on the clamp (45), and the clamp (45) can be rotated by turning the gear handle (62);

[0047] 3) Rotate the clamp (45) in the opposite direction to make the guide limit groove (85) turn to the position of the notch disc (79) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com