A kind of recombinant carbonyl reductase mutant, gene, engineering bacteria and application thereof

A mutant, reductase technology, applied in genetic engineering, oxidoreductase, applications, etc., can solve the problems of insufficient diastereomeric induction, failure to meet production requirements, low optical purity of products, etc., and shorten the reaction time. , the effect of reducing the reaction cost and simplifying the chemical catalysis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Obtaining of recombinant carbonyl reductase mutants

[0037] Using the recombinant bacteria (E.coli BL21(DE3) / pET28b-SCR) containing the expression vector pET28b-SCR as the starting strain, through random mutation and site-directed saturation mutation techniques, the ability of carbonyl reductase to substrate (S)-CHOH was further improved. Catalytic activity and substrate tolerance.

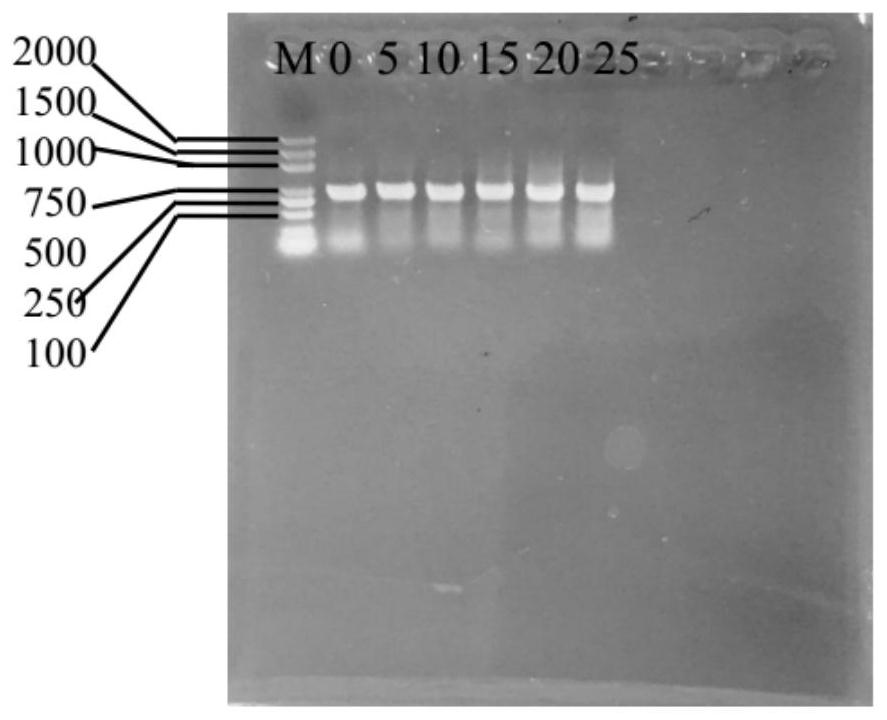

[0038] (1) Error-prone PCR and PCR with large primers

[0039] Error-prone PCR upstream primer 1: 5'-TATGTCTTCGCCTACTCCCAAC-3'

[0040] Error-prone PCR downstream primer 2: 5'-TCTACCATGGCAAGAACGTCC-3'

[0041] Error-prone PCR by changing the Mn in the PCR system 2+ , Mg 2+ The wrong bases are randomly incorporated into the amplified gene at a certain frequency, so as to obtain a randomly mutated DNA population. The present invention uses the plasmid DNA where the SCR gene (the nucleotide sequence is shown in SEQ ID NO.1 and the amino acid sequence is shown in SEQ ID NO.2) a...

Embodiment 2

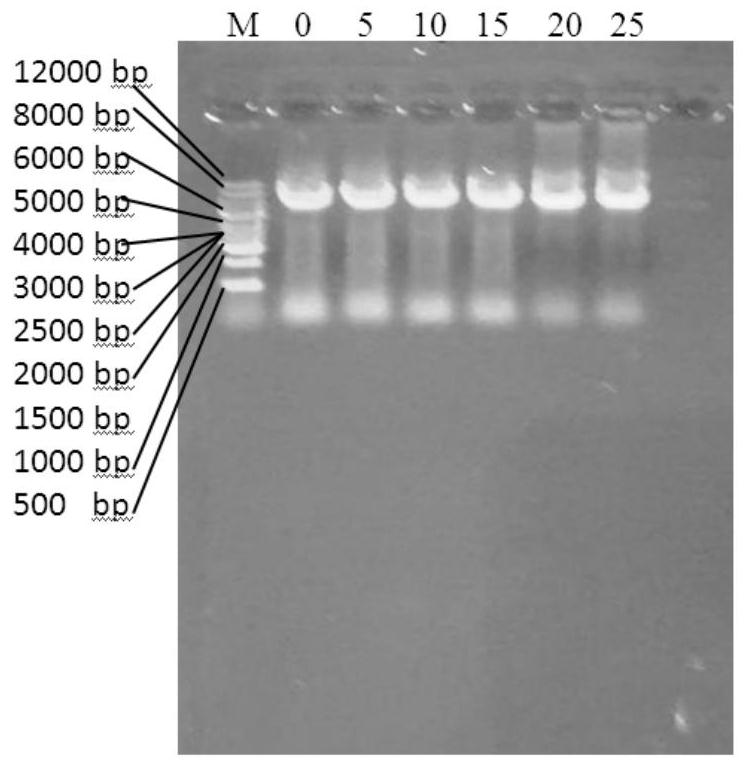

[0115] Example 2: Preparation of recombinant carbonyl reductase mutant wet thallus

[0116] The recombinant Escherichia coli (recombinant Escherichia coli BL21(DE3) / pET28b-mut-Phe145Met / Thr152Ser, recombinant Escherichia coli BL21(DE3) / pET28b-mut-Phe145Tyr / Thr152Ser) was inoculated into LB liquid medium containing kanamycin resistance at a final concentration of 50 μg / mL, cultured at 37°C and 180 rpm for 8 hours, and then inoculated with a 1% inoculum amount (v / v) into fresh LB medium containing a final concentration of 50 μg / mL In mL kanamycin-resistant LB liquid medium, culture at 37°C and 180rpm until the cell OD 600 After reaching 0.6-0.8, add IPTG with a final concentration of 0.1mM, induce culture at 28°C for 12h, then centrifuge at 8000rpm for 10min at 4°C, discard the supernatant, collect the precipitate, and obtain the recombinant carbonyl reductase mutant gene. Recombinant Escherichia coli wet cells. The wet thalline can be used directly as a biocatalyst or for pr...

Embodiment 3

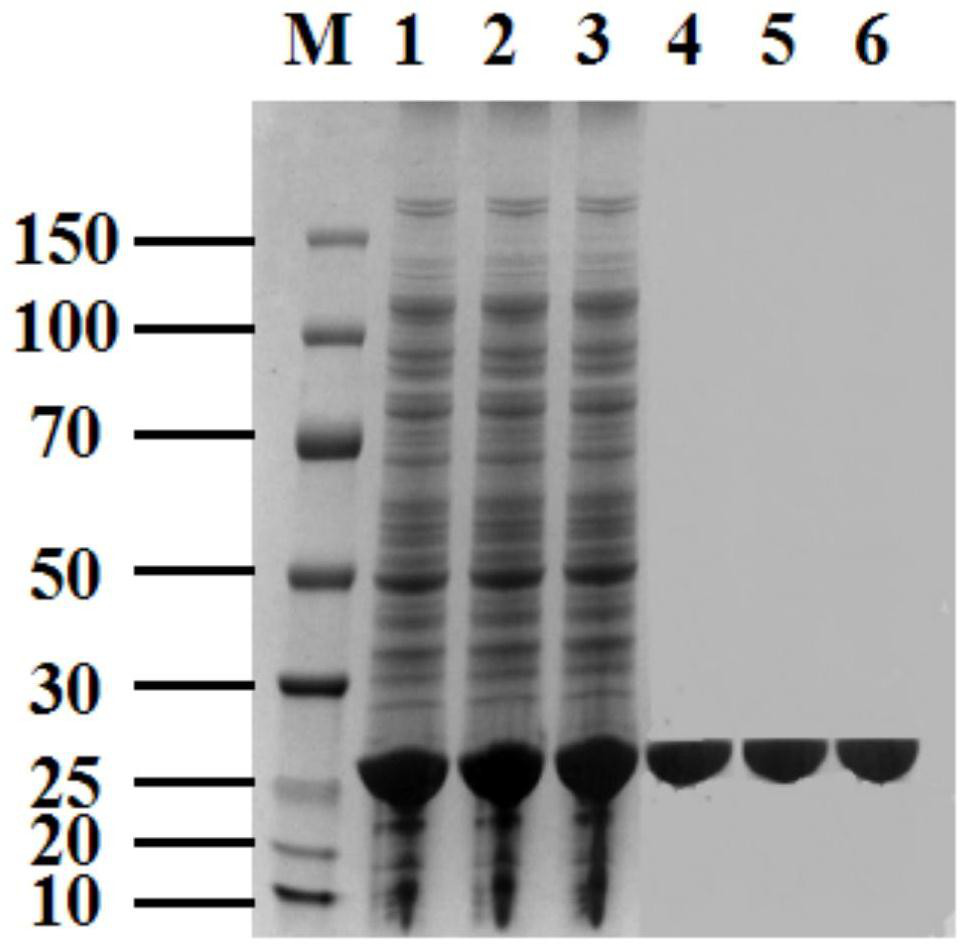

[0117] Embodiment 3: Separation and purification of carbonyl reductase mutant

[0118] The wet cells obtained in Example 3 were washed three times with physiological saline, and the wet cells were resuspended according to 1 g of wet cells plus 20 mL of 20 mM, pH 7.0 potassium phosphate buffer, and ultrasonically crushed under ice bath conditions (60 W, continuous 1s, intermittent 1s, continuous disruption for 30min) to obtain cell disruption liquid. The cell lysate obtained after ultrasonic disruption was centrifuged at 8000 rpm and 4° C. for 25 min, and the obtained supernatant was the required crude enzyme solution, which was designated as crude enzyme solution I.

[0119] Fractional salting out of ammonium sulfate: determination of the optimum precipitation concentration, the most commonly used salt in salting out is (NH 4 ) 2 SO 4 、Na 2 SO 4 , MgSO 4 . (NH 4 ) 2 SO 4 Because of its high solubility, small temperature coefficient, good separation effect, generally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com