High-pixel wide-angle lens

A wide-angle lens, high-pixel technology, applied in the field of optical lenses, can solve the problems that the finished product is not light enough, the relative illumination is low, and the production cost is high, and achieves the effect of low weight, aberration correction, and improved imaging clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

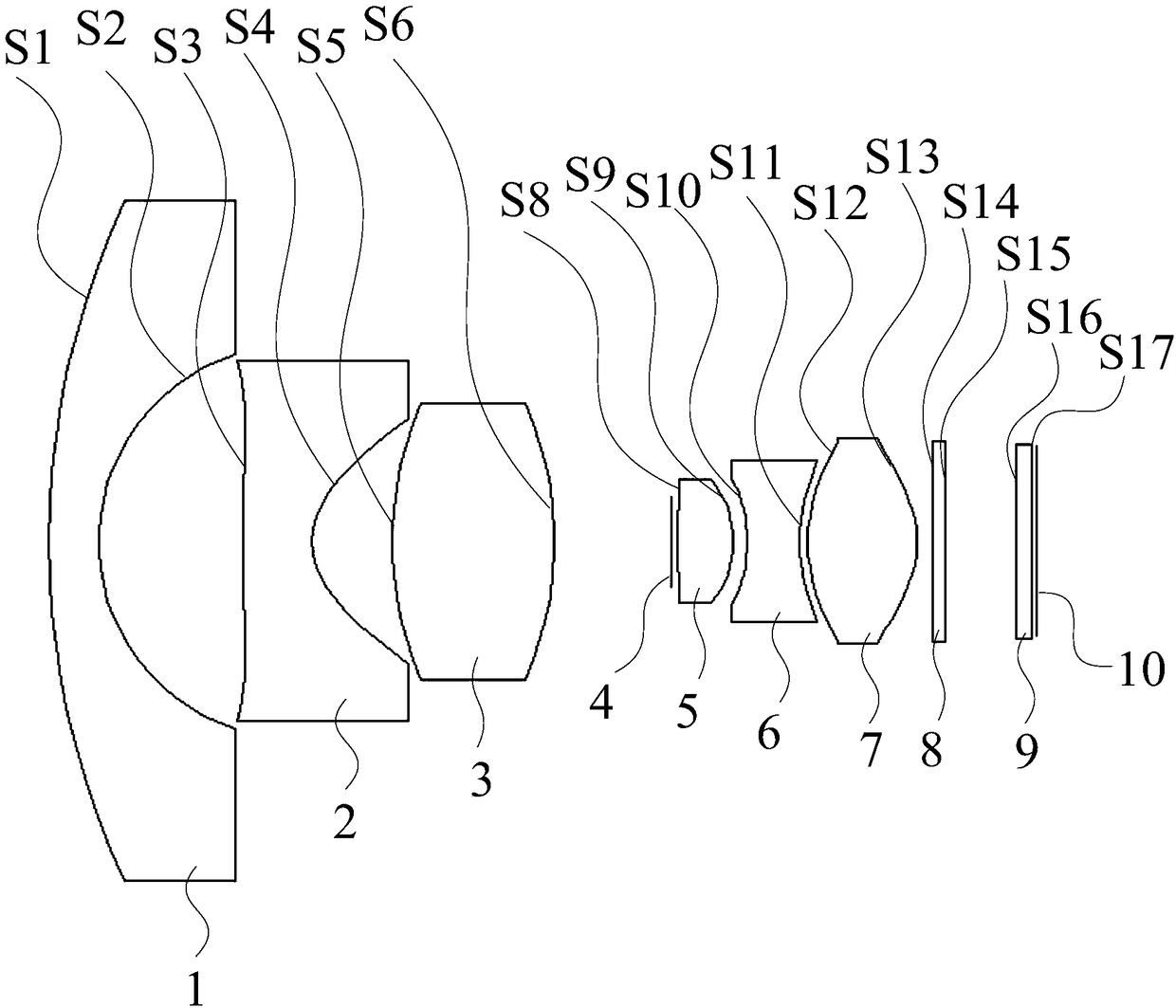

[0041] The following combination Figure 1 ~ Figure 4 The specific implementation manners of the present invention will be further elaborated.

[0042] A high-pixel wide-angle lens, which is sequentially provided with from the object side to the image side: the first lens 1, the object side is convex, and the image side is concave; the second lens 2, the object side is convex, and the image side is concave; Lens 3, its object side and image side are both convex; stop 4; fourth lens 5, its object side and image side are both convex; fifth lens 6, its object side and image side are both concave; sixth lens 7. Both the object side and the image side are convex. The combination of concave and convex structures adopted by each lens in this solution can achieve better aberration correction performance through rational distribution of optical power, thereby improving imaging clarity.

[0043] Optionally, a filter 8 may also be provided between the sixth lens 7 and the photosensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com