Weak current engineering wire pipe connecting device

A technology for line pipe connection and weak current engineering, applied in electrical components and other directions, can solve the problems of unstable connection structure of insulating pipes, inaccurate installation and positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

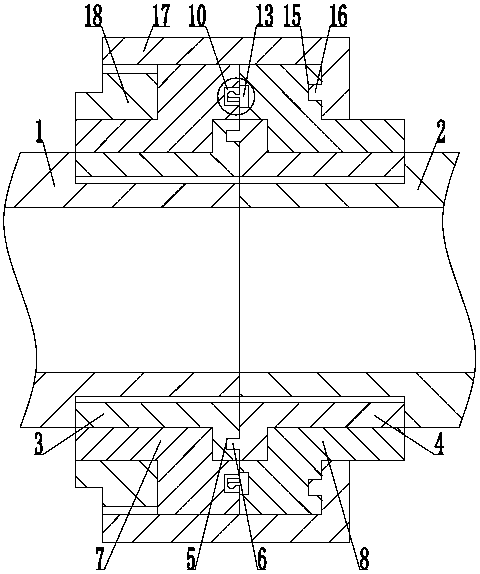

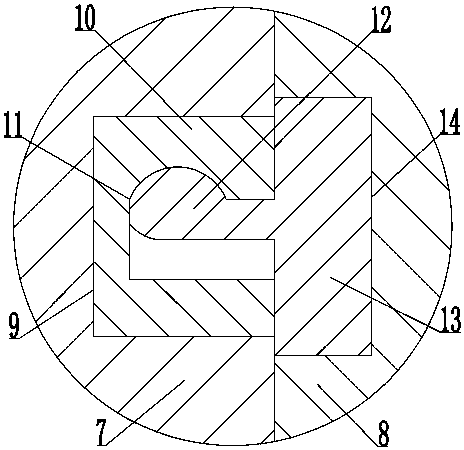

[0011] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0012] A line pipe connection device for weak current engineering, comprising an insulating pipe 1, a matching insulating pipe 2, a mounting pipe 3, a matching mounting pipe 4, a mounting sleeve 7, a matching mounting sleeve 8, a positioning sleeve 10, a positioning block 13, a fastening sleeve 17, Fasten the flange 18, the outside of the insulating pipe 1 is connected to the installation pipe 3 by threads, the outside of the installation pipe 3 is adapted to the installation sleeve 7, the installation sleeve 7 is connected to the installation pipe 3, and the matching insulation pipe 2 is threaded Connect with the installation pipe 4, the installation pipe 4 is compatible with the installation pipe 3, the installation pipe 3 is connected with the installation pipe 4, the installation pipe 4 has the installation protrusion 6, and the installation pipe 3 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com