Chipless pipe cutting machine

A kind of pipe cutting machine, organic technology, applied in the field of chipless pipe cutting machine, can solve the problems of surrounding environment pollution, large debris, mixed burrs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

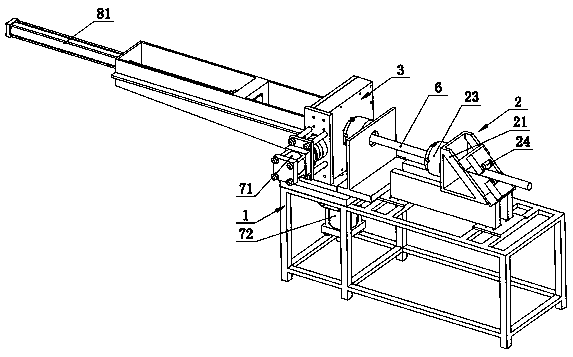

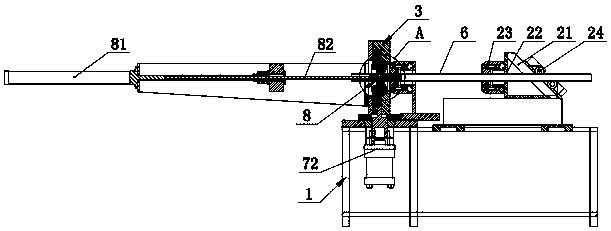

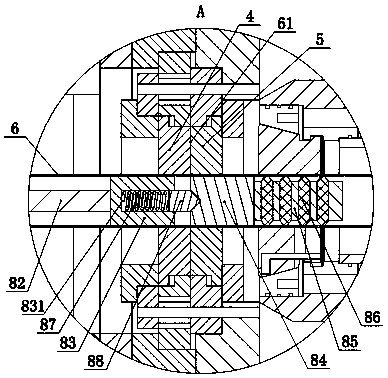

[0017] Such as Figure 1-5 Shown is a chipless pipe cutting machine, including a frame 1, a metal pipe clamping mechanism 2 and a mold frame 3 are arranged on the frame 1, and a movable mold plate 4 and a mold frame 3 are arranged in the mold frame 3. The static mold plate 5, the movable mold plate 4 is correspondingly provided with a movable mold cavity 41 for the metal pipe 6 to penetrate axially, the static mold plate 5 is correspondingly provided with a static mold cavity 51 for the metal pipe 6 to penetrate axially, and the movable mold The cavity 41 and the static mold cavity 51 are arranged coaxially, the static mold plate 5 is fixed to the mold frame 3, the movable mold plate 4 is movably arranged on the mold frame 3, and the movable mold plate 4 is connected to drive its relative static mold plate. The disk 5 is axially attached to the oscillating power mechanism 7 .

[0018] With the above-mentioned structure, when cutting, the metal tube 6 is clamped and fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com