Carbon crucible vibration forming machine

A vibration molding machine and carbon crucible technology, which is applied to ceramic molding machines, supply devices, ceramic extrusion dies, etc., can solve the problems of high production cost and complicated processing technology of square crucibles, and achieve uniform wall thickness, uniform heat conduction, and thick and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure and characteristics of a carbon crucible vibration molding machine proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. And its effect, detailed description is as follows.

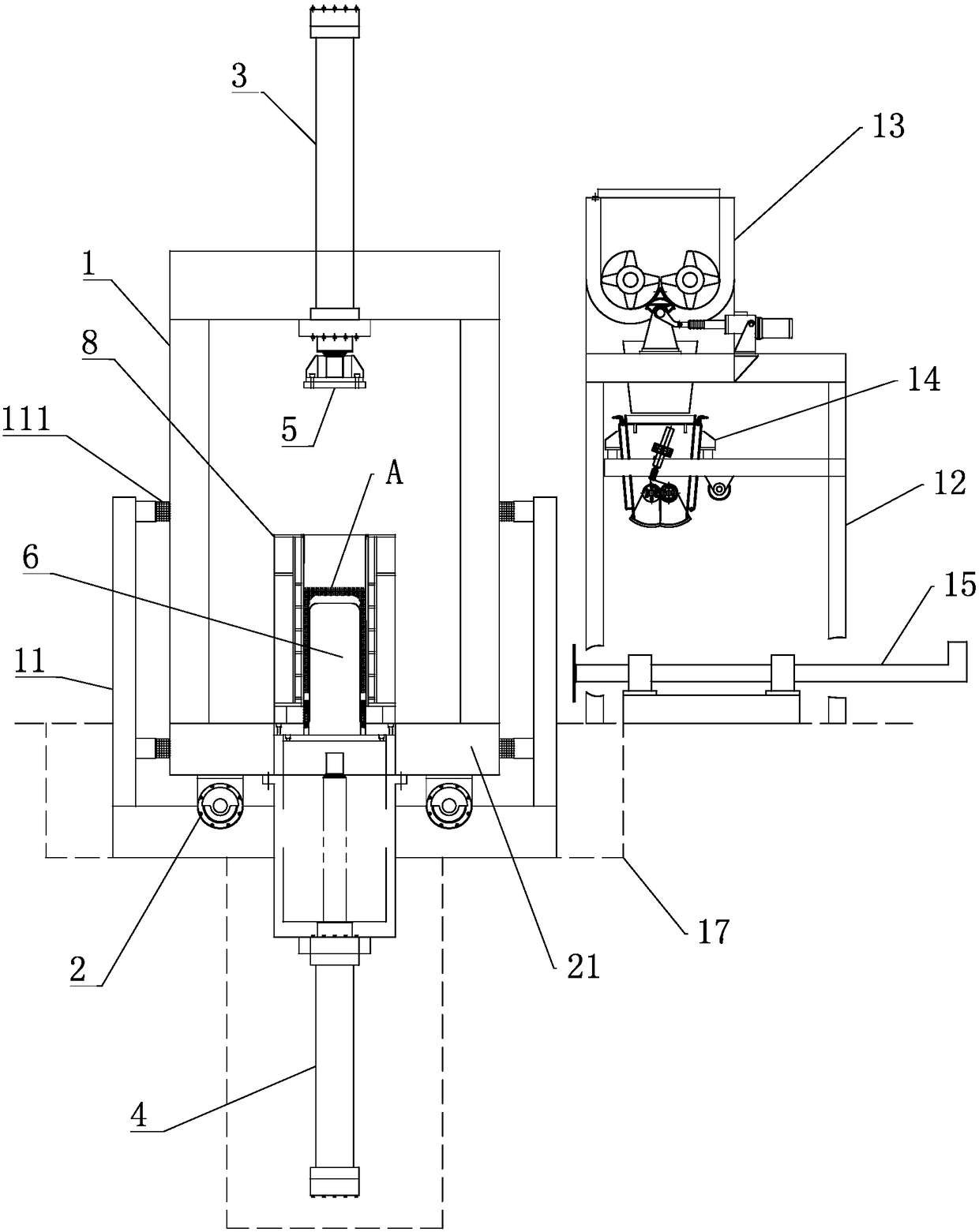

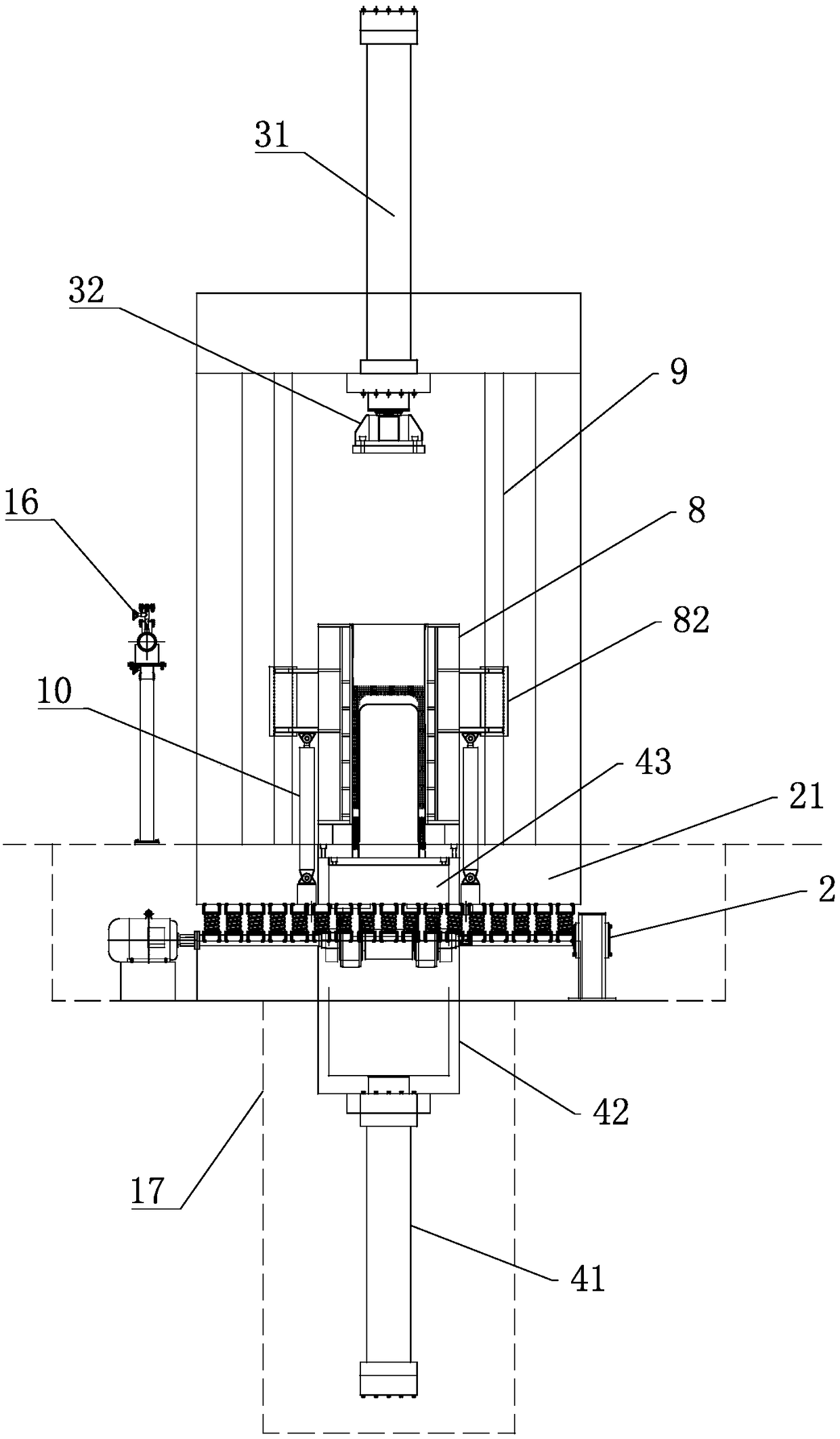

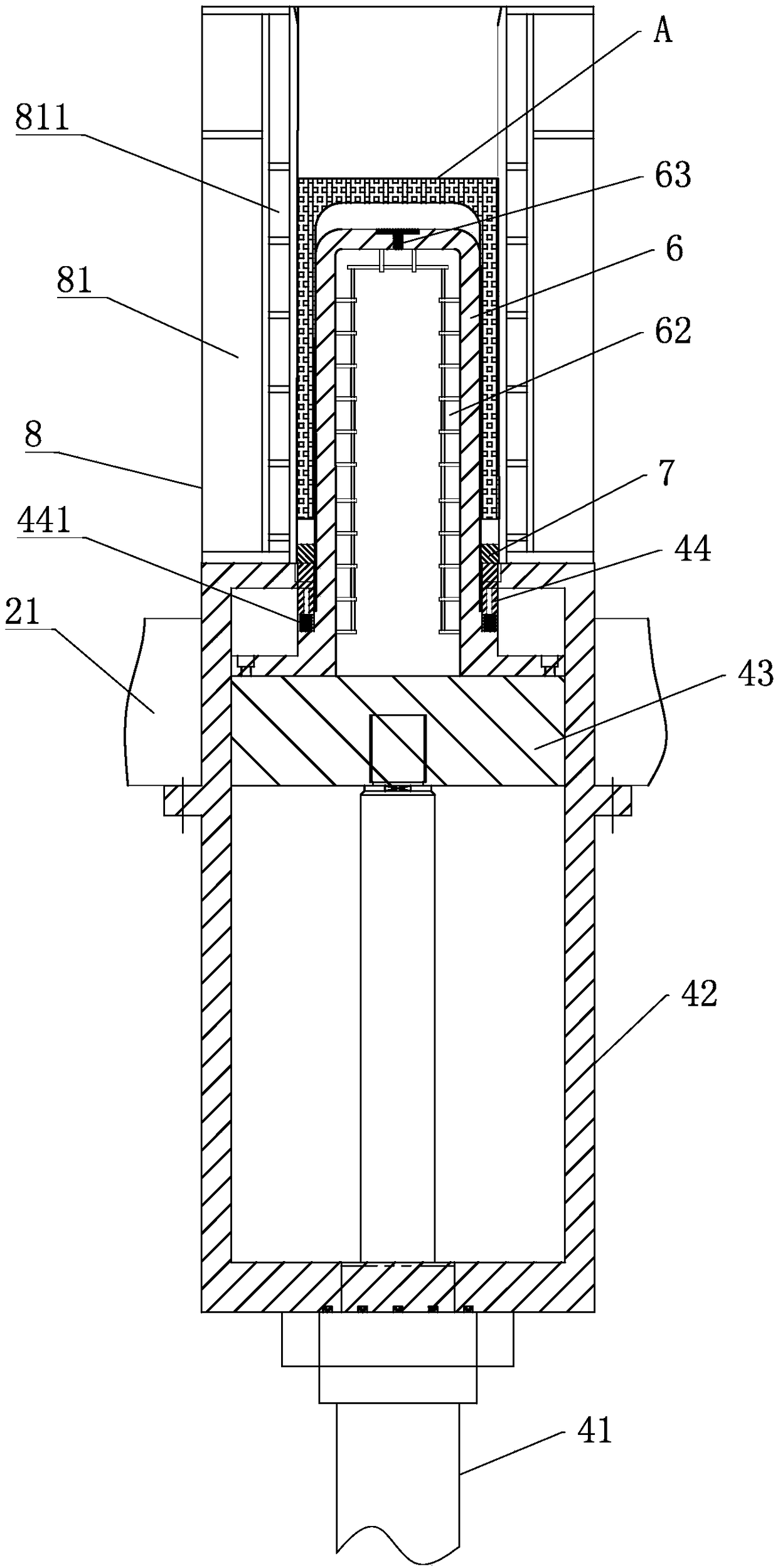

[0036] see Figure 1 to Figure 6 , a carbon crucible vibration molding machine of the present invention includes a main frame 1, an amplitude modulation vibration table 2, an upper pressing mechanism 3, and a lower pressing mechanism 4, wherein the amplitude modulation vibration table 2 is fixedly installed on the equipment foundation 17.

[0037] The upper pressing mechanism 3 is installed on the top of the main frame 1, and the lower part of the upper pressing mechanism 3 is equipped with an upper die 5, and the lower part of the main frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com