Multifunctional logistics tray and adjusting and assembling method thereof

A multi-functional and logistics technology, applied in transportation and packaging, packaging, rigid containers, etc., can solve problems such as affecting the bottom structure of the logistics board, the forklift cannot be placed stably, and affecting the transfer of the forklift, so as to avoid accidental adjustment and pallet movement. Process-safe, well-structured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

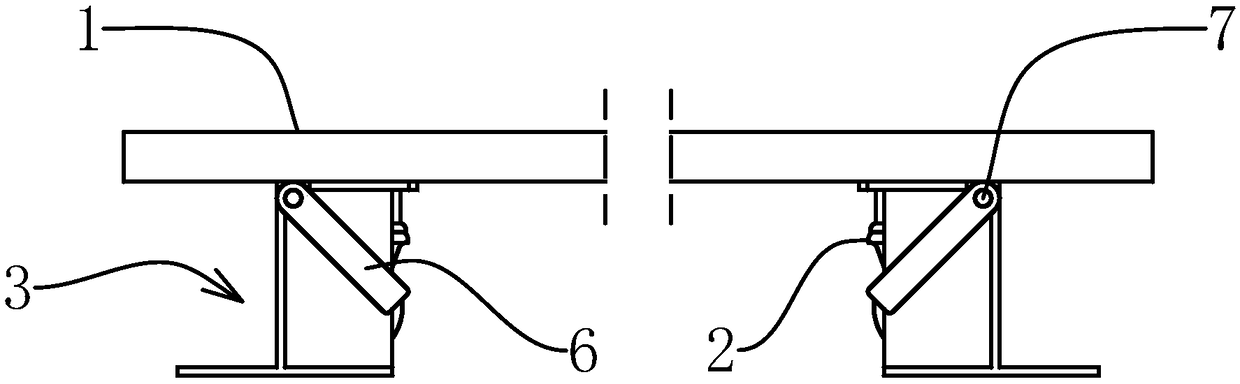

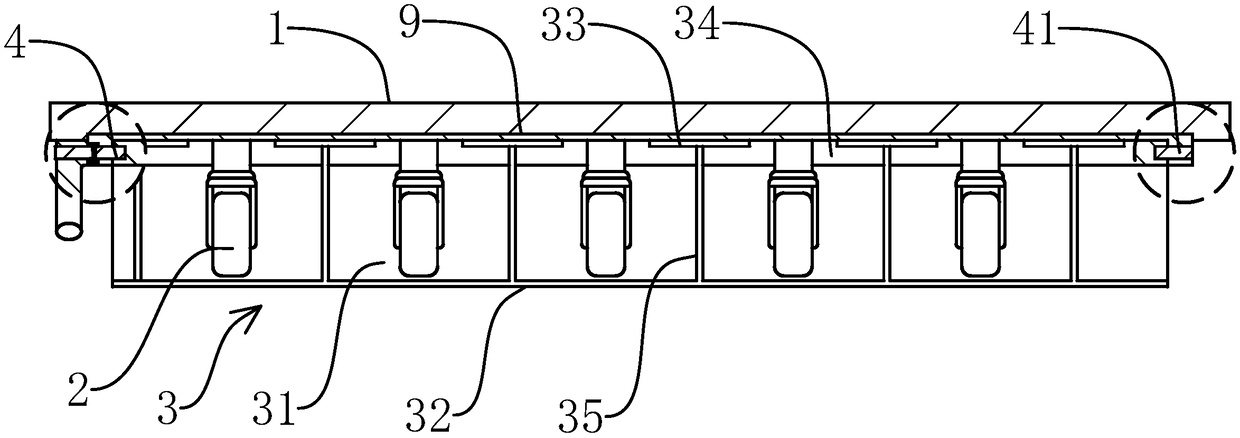

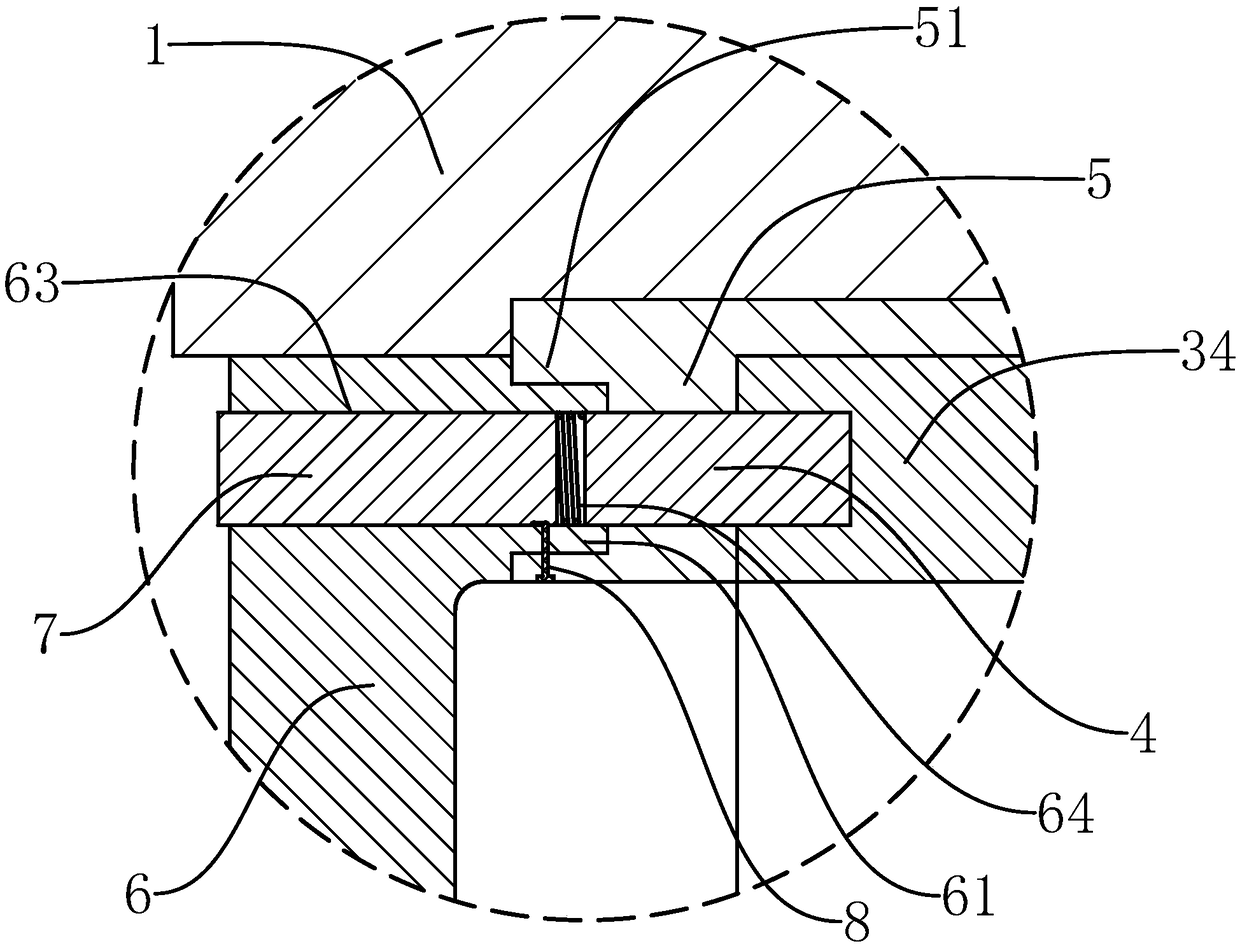

[0047] Such as Figure 1-8 As shown, a multifunctional logistics pallet of the present invention includes a rectangular plate-shaped logistics pallet 1, the top surface of the pallet 1 is parallel to the bottom surface, and the bottom surface of the pallet 1 is provided with two roller mechanisms. and a row of universal rollers 2 distributed along the width direction of the bottom surface of the pallet 1, and the two rows of universal rollers 2 corresponding to the two roller mechanisms are respectively arranged close to the wide sides of the bottom surface of the pallet 1, and the roller mechanism also includes strips Steel structure support seat 3, support seat 3 includes support plate 31, lower baffle plate 32 and sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com