Glass semi-finished product transferring support

A technology of semi-finished products and transfer racks, which is applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc. It can solve the problems of increased workload, product quality impact, and vulnerability to scratches for repaired products, so as to reduce manual handling and reduce prices. , space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

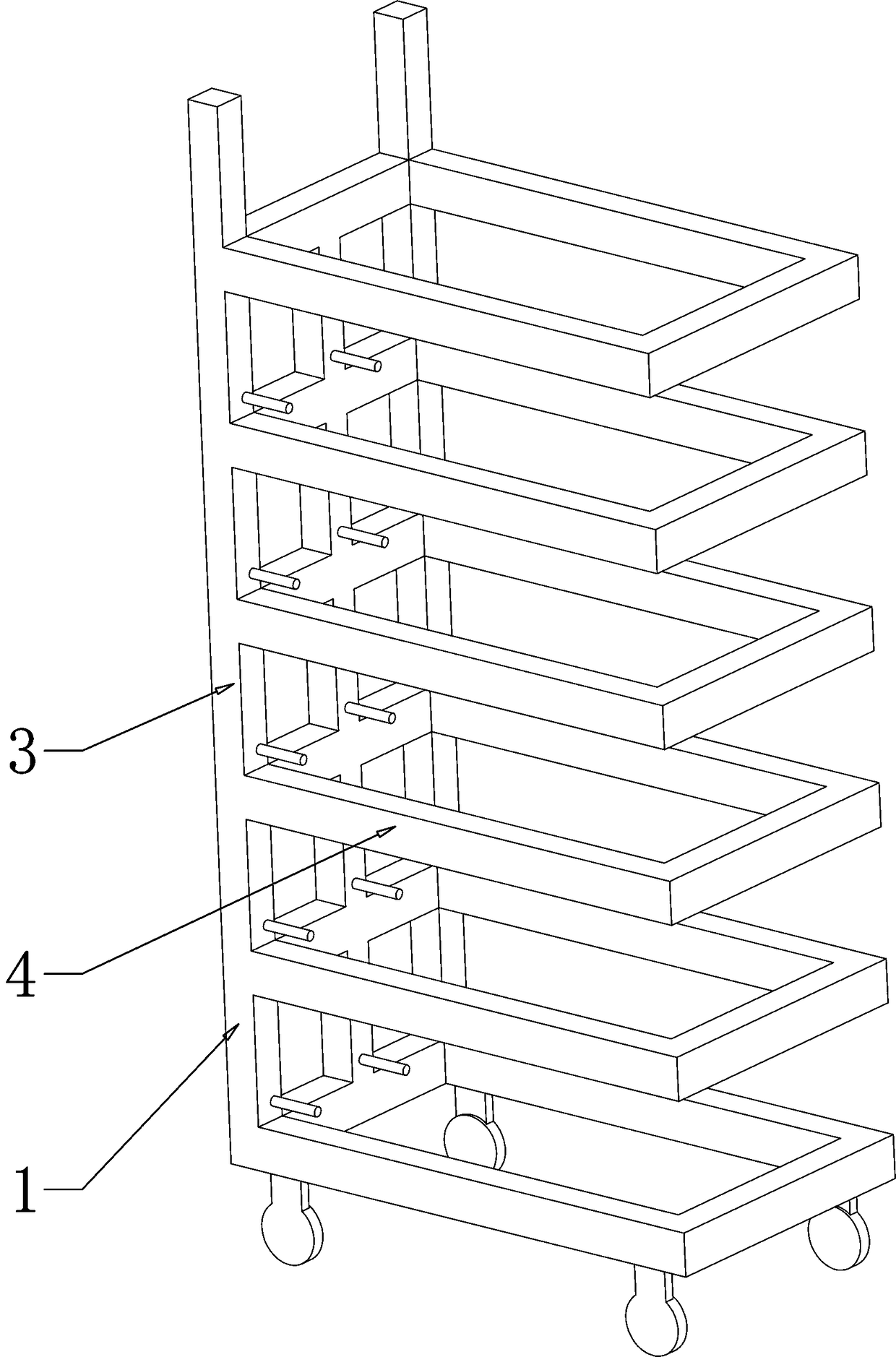

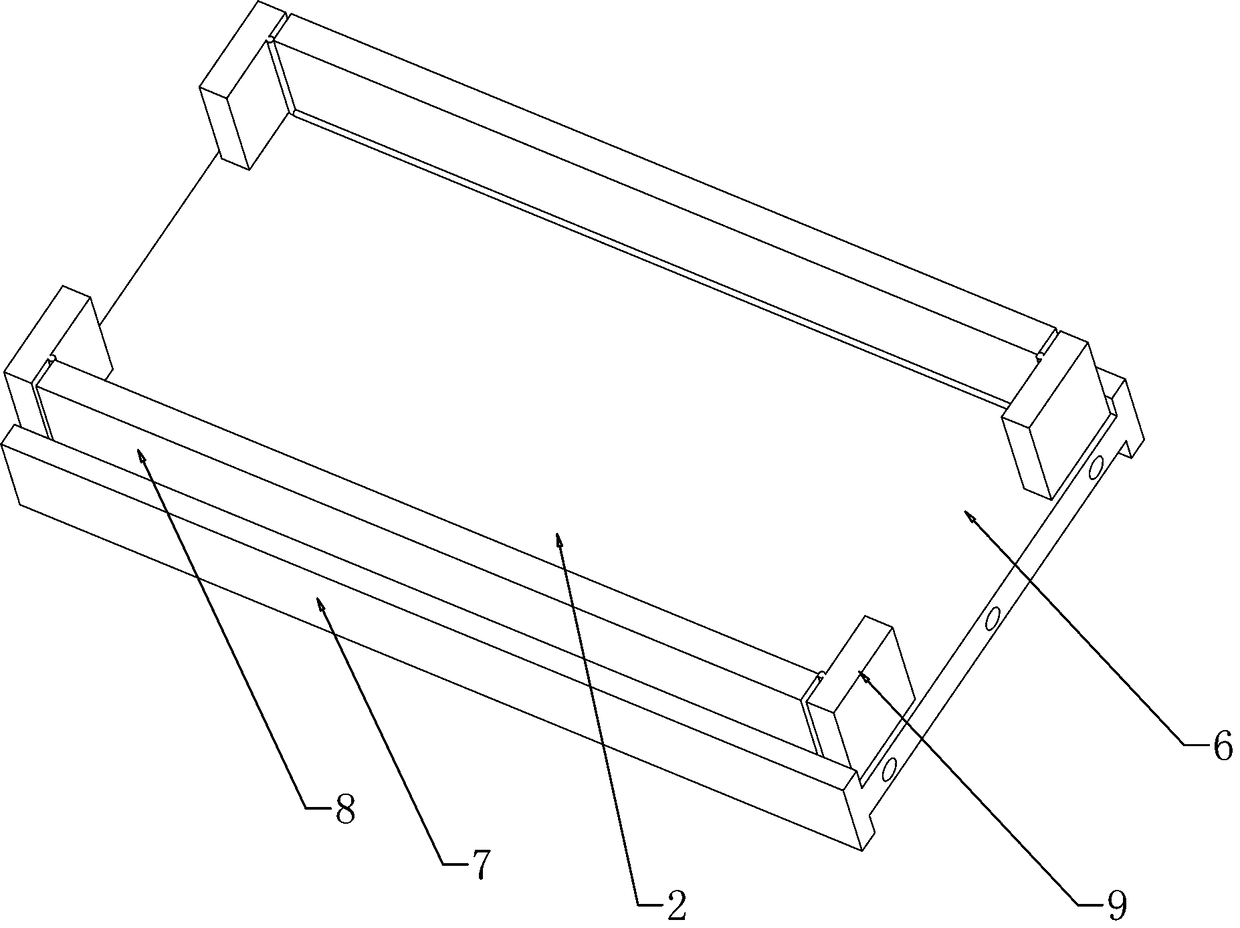

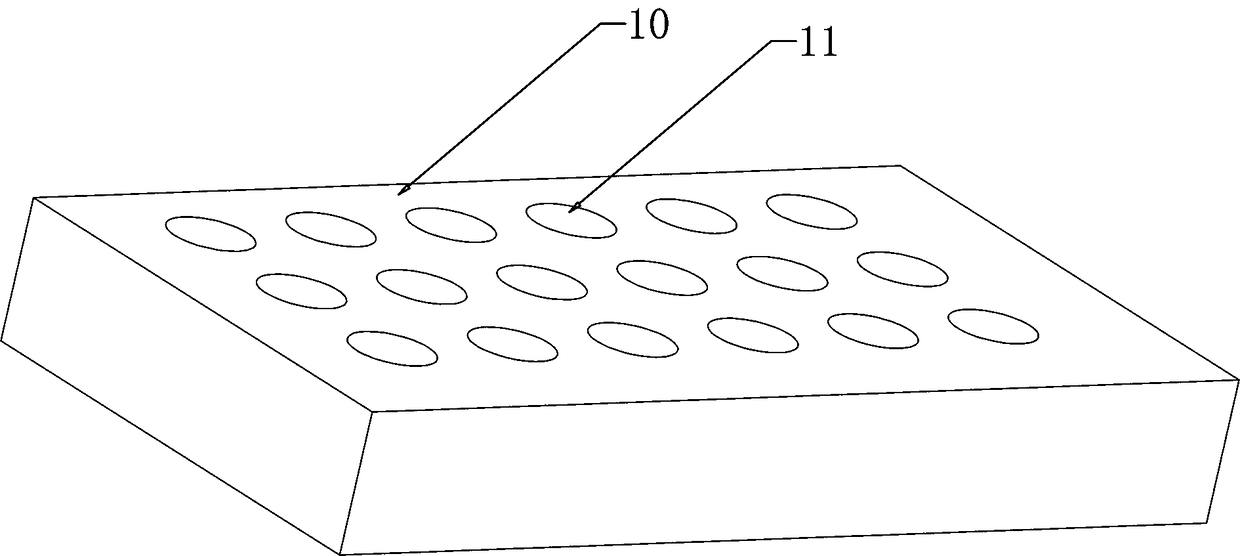

[0019] like Figure 1-3 As shown, a transfer frame for glass semi-finished products includes a mobile frame 1 and a sliding tray 2. The mobile frame 1 includes a frame body 3, the lower end of the frame body 3 is provided with universal wheels, and the upper end of the frame body 3 is equidistantly provided with a plurality of square wheels. The frame slide rail 4 is provided with a hole at the rear end of the frame slide rail 4, and a bayonet pin 5 is inserted in the hole; the sliding tray 2 includes a bottom plate 6, and both sides of the bottom plate 6 are provided with a limit plate 7, and the upper and lower ends of the limit plate 7 extend Out of the bottom plate 6. The lower end of the limiting plate forms a pull-type sliding connection with the frame slide rail 4, and the upper end of the limiting plate is used as a limiting beam, which can be limited when the first baffle plate 8 and the second baffle plate 9 are turned up. Because the front and rear ends of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com