Easy-to-process heat-resistant polyethylene composition and its preparation method

A technology of heat-resistant polyethylene and composition, which is applied in the field of easy-processing heat-resistant polyethylene composition and its preparation, can solve the problems of low critical shear rate and narrow molecular weight distribution of pipe materials, and achieve high and excellent pressure resistance The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

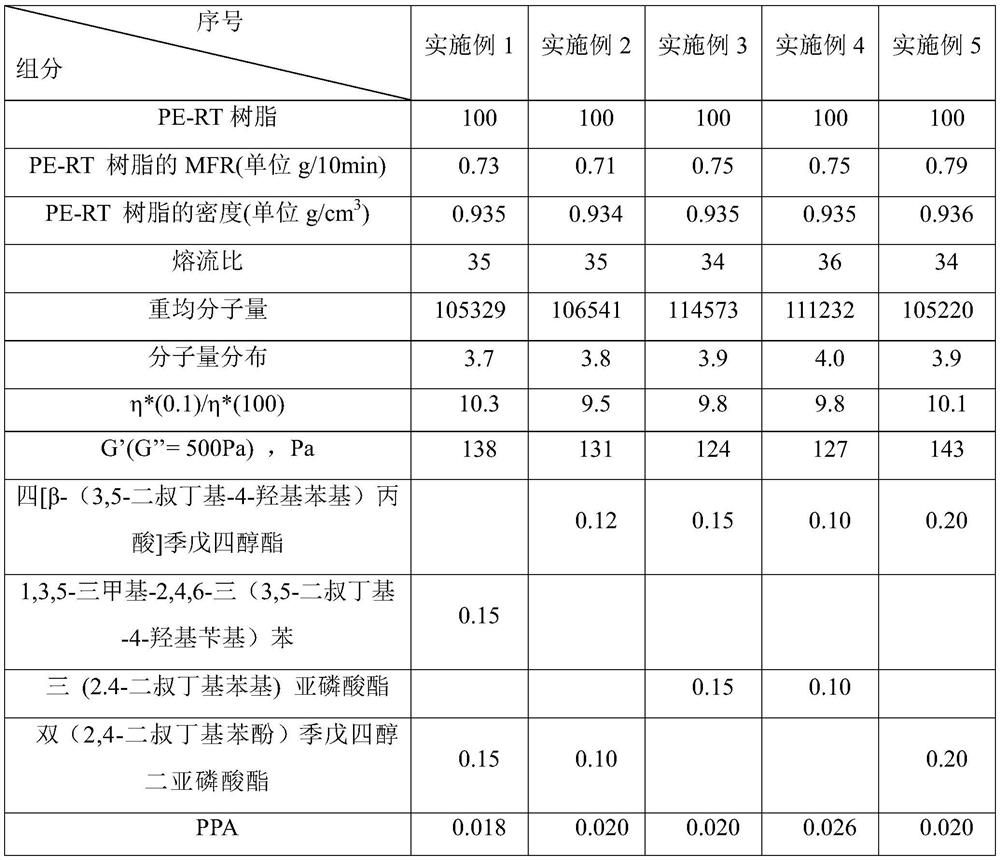

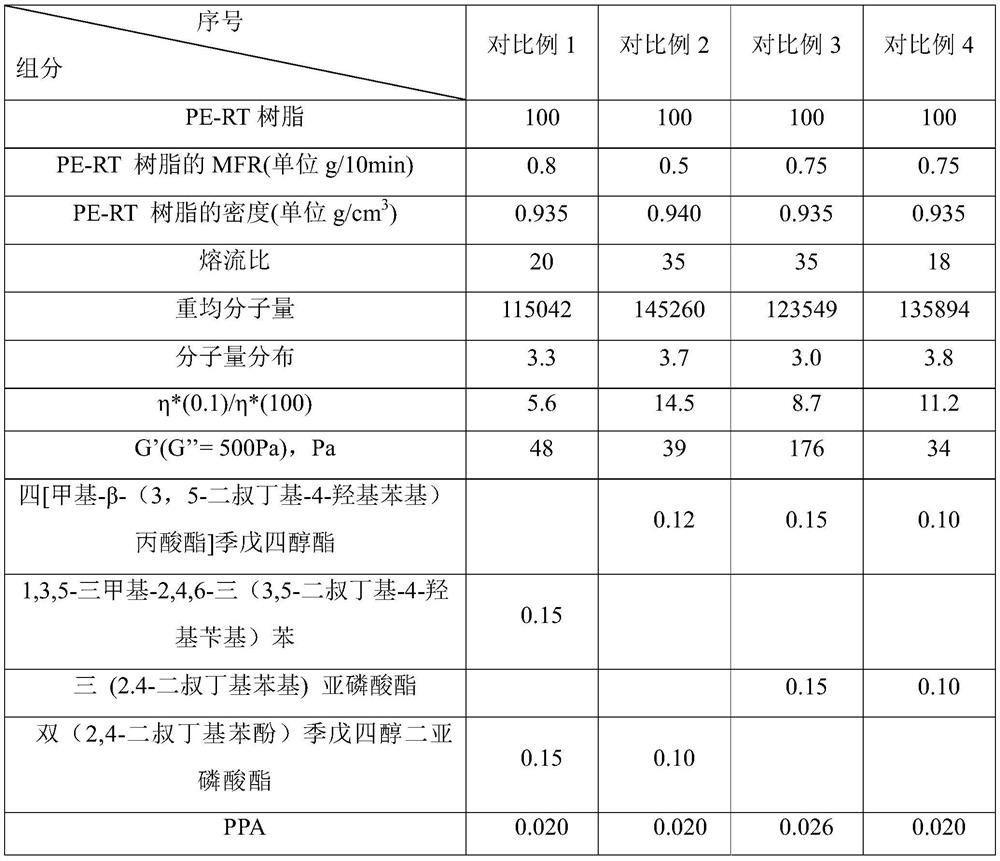

[0031] The proportioning components of the easy-to-process heat-resistant polyethylene composition used in the production of heat-resistant polyethylene pipes are shown in Table 1.

[0032]Density is tested according to GB / T 1033.2-2010, using method D, tested after boiling for 30 minutes; melt mass flow rate (MFR) is tested according to GB / T 3682-2000, with a load of 2.16kg; molecular weight and its distribution are tested using gel Permeation chromatography (GPC) method, two chromatographic columns are connected in series, the solvent and mobile phase are both 1,2,4-trichlorobenzene (containing 0.1% antioxidant 2,6-dibutyl-p-cresol), the column temperature 150°C, dissolved for 4 hours, flow rate 1.0ml / min, using narrow distribution polystyrene standard sample for universal calibration; material storage modulus, energy loss modulus, complex shear viscosity using rotational rheology, ф25mm parallel plate, The gap between the parallel plates is 1mm, at 190°C at 10 -1 A dynamic...

Embodiment 6

[0046] Performance test experiment

[0047] The notched impact strength is tested according to GB / T 1043.1-2008, A-type notch, 23 ° C on domestic equipment and imported equipment to conduct the processing test of ф20*2.0mm floor heating pipes, record the processing speed and current; the composition is prepared into After the pipe with the specification of ф20*2.0mm, the hydrostatic strength of the pipe is tested according to GB / T 18252-2000; the capillary rheological property is tested according to GB / T25278-2010 to obtain the critical shear rate of the pipe material, and the test temperature is 200°C .

[0048] The performance test results are shown in Table 3-4.

[0049] Table 3 embodiment 1-5 performance test result

[0050] Test items Example 1 Example 2 Example 3 Example 4 Example 5 Charpy notched impact strength, kJ / m 2

38 41 36 36 33 critical shear rate, s -1

350 300 400 500 400 Extrusion processing speed, m / min 33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com