Clothing partial cleaning structure and washing machine

A washing machine and local technology, applied to other washing machines, oscillating washing machines, washing devices, etc., can solve the problems of increasing operation steps, difficult to master, increasing operation time, etc., achieving simple and convenient operation, saving washing time, and simple cleaning structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

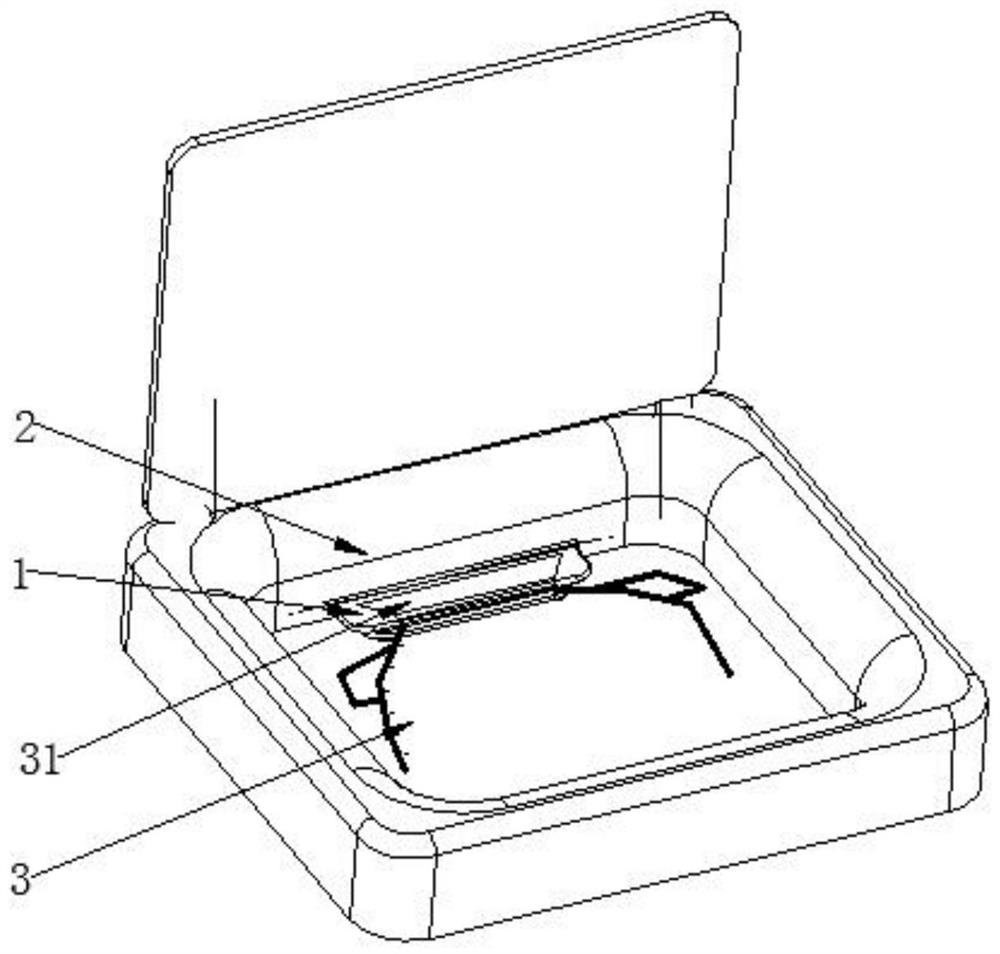

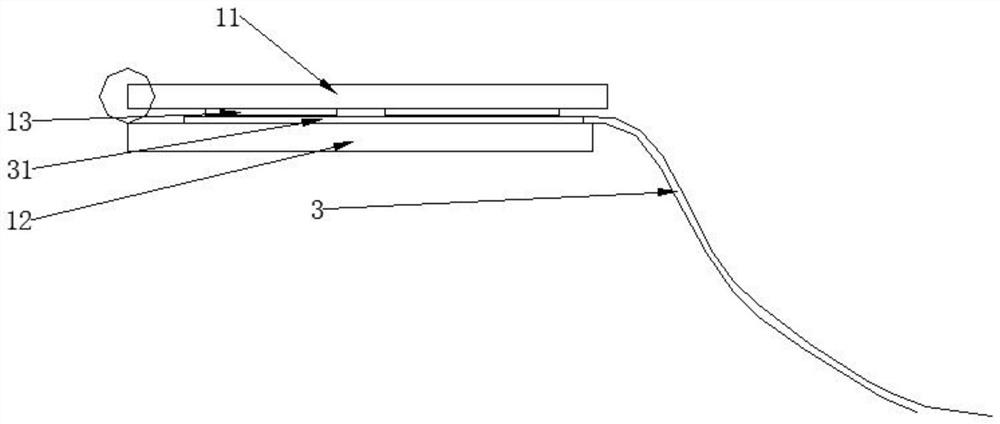

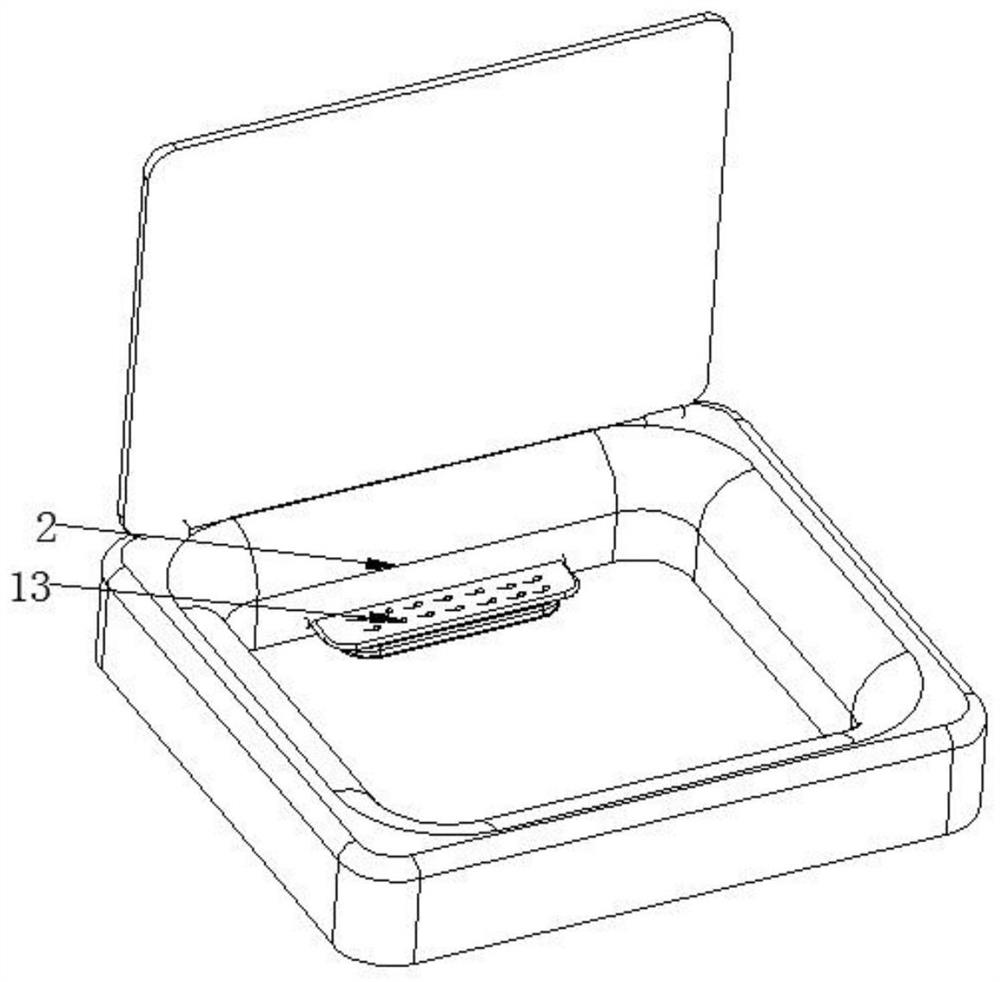

[0049] Such as Figure 1 to Figure 5 As shown, in this embodiment, a washing machine is provided, which includes a partial laundry cleaning structure 1, and the partial laundry cleaning structure 1 is detachably arranged on the washing machine tray 2, such as Figure 1-Figure 2 As shown, the local clothing cleaning structure 1 includes a pressing plate 11 and a supporting plate 12, the pressing plate 11 includes an ultrasonic transducer 13, the supporting plate 12 includes a water inlet cavity 122, the shape of the pressing plate 11 and the support After the plates 12 are matched and pressed against the direction of the support plate 12, a slit for clamping the part 31 of the clothes to be washed is formed between each other, and the clothes 3 are clamped and the parts to be washed are ultrasonically cleaned.

[0050] Such as Figure 2-Figure 3 As shown, at least one ultrasonic hole is provided on the pressing plate 11, and the ultrasonic transducer 13 is embedded in the pres...

Embodiment 2

[0058] Such as Figure 1 to Figure 5 As shown, in this embodiment, a washing machine is provided, which includes a partial laundry cleaning structure 1, and the partial laundry cleaning structure 1 is detachably arranged on the washing machine tray 2, such as Figure 1-Figure 2 As shown, the local clothing cleaning structure 1 includes a pressing plate 11 and a supporting plate 12, the pressing plate 11 includes an ultrasonic transducer 13, the supporting plate 12 includes a water inlet cavity 122, the shape of the pressing plate 11 and the support After the plates 12 are matched and pressed against the direction of the support plate 12, a slit for clamping the part 31 of the clothes to be washed is formed between each other, and the clothes 3 are clamped and the parts to be washed are ultrasonically cleaned.

[0059] Such as figure 2 As shown, in the present embodiment, the pressure plate 11 is rotatably installed relative to the support plate 12, lifts or compresses the su...

Embodiment 3

[0064] Such as Figure 1 to Figure 5 As shown, in this embodiment, a washing machine is provided, which includes a partial laundry cleaning structure 1, and the partial laundry cleaning structure 1 is detachably arranged on the washing machine tray 2, such as Figure 1-Figure 2 As shown, the local clothing cleaning structure 1 includes a pressing plate 11 and a supporting plate 12, the pressing plate 11 includes an ultrasonic transducer 13, the supporting plate 12 includes a water inlet cavity 122, the shape of the pressing plate 11 and the support After the plates 12 are matched and pressed against the direction of the support plate 12, a slit for clamping the part 31 of the clothes to be washed is formed between each other, and the clothes 3 are clamped and the parts to be washed are ultrasonically cleaned.

[0065] Such as figure 2 As shown, in this embodiment, the pressing plate 11 is fixedly installed relative to the supporting plate 12, and the part 31 of the clothes t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap