An explosion-proof exterior wall with pressure relief function

A functional and external wall technology, applied in the direction of walls, ventilation systems, heating methods, etc., can solve the problems of secondary injury to personnel, poor sealing effect of shutters, and rapid diffusion of unprofitable high-pressure air waves. Improve the effect of anti-knock and pressure relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

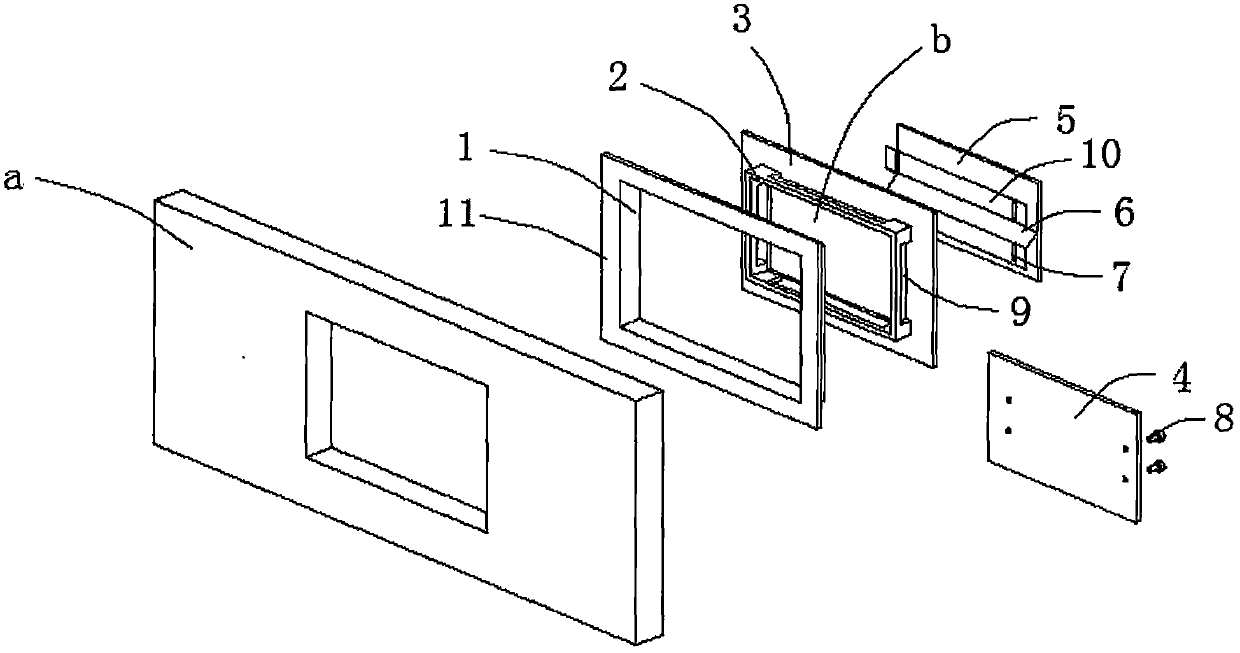

[0012] see figure 1 , this specific embodiment is realized by adopting the following technical scheme, which includes a ventilation pipe 1 located in the explosion-proof wall a, the interior of the ventilation pipe 1 is provided with a pressure relief pipe 2, and the outer surface of the pressure relief pipe 2 is in contact with There is a cavity for high-pressure air waves to pass between the inner walls of the ventilation pipe 1, and the end of the pressure relief pipe 2 is welded vertically on the baffle 3, and the end of the pressure relief pipe 2 opposite to the baffle 3 A positioning plate 4 is welded and fixed, and the baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com