Prefabricated UHPC formwork concrete-filled bridge guardrail and construction method thereof

A construction method and concrete technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of time-consuming template construction, large on-site workload, slowing down the construction progress, etc. Reduce the effect of formwork engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

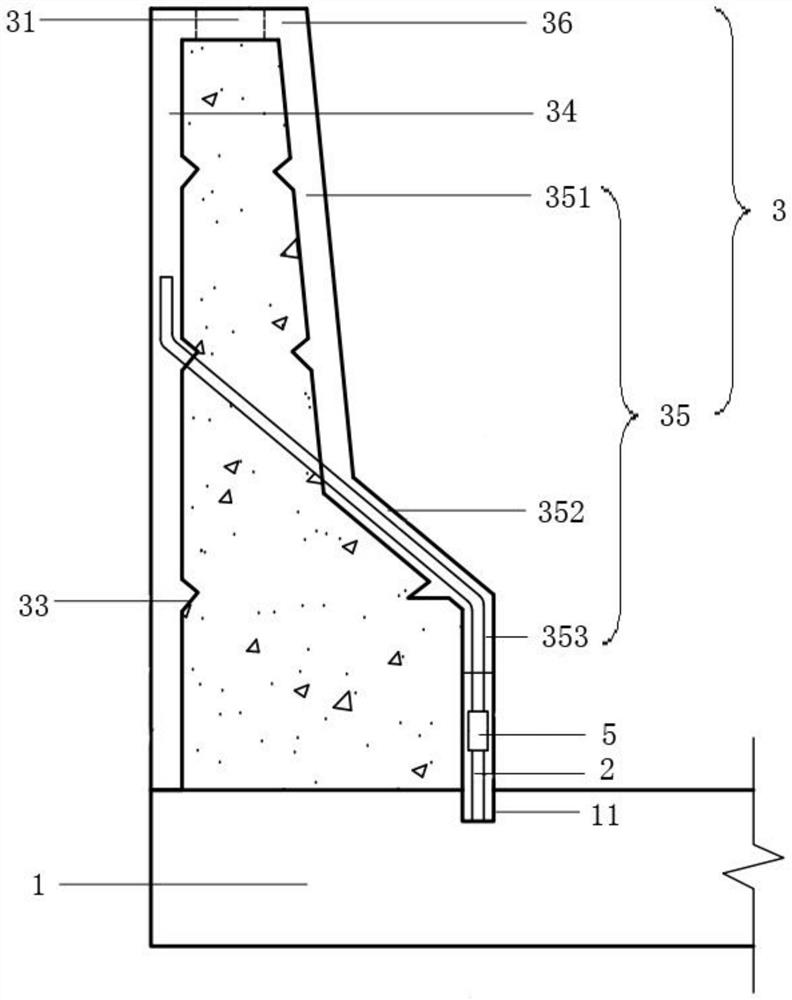

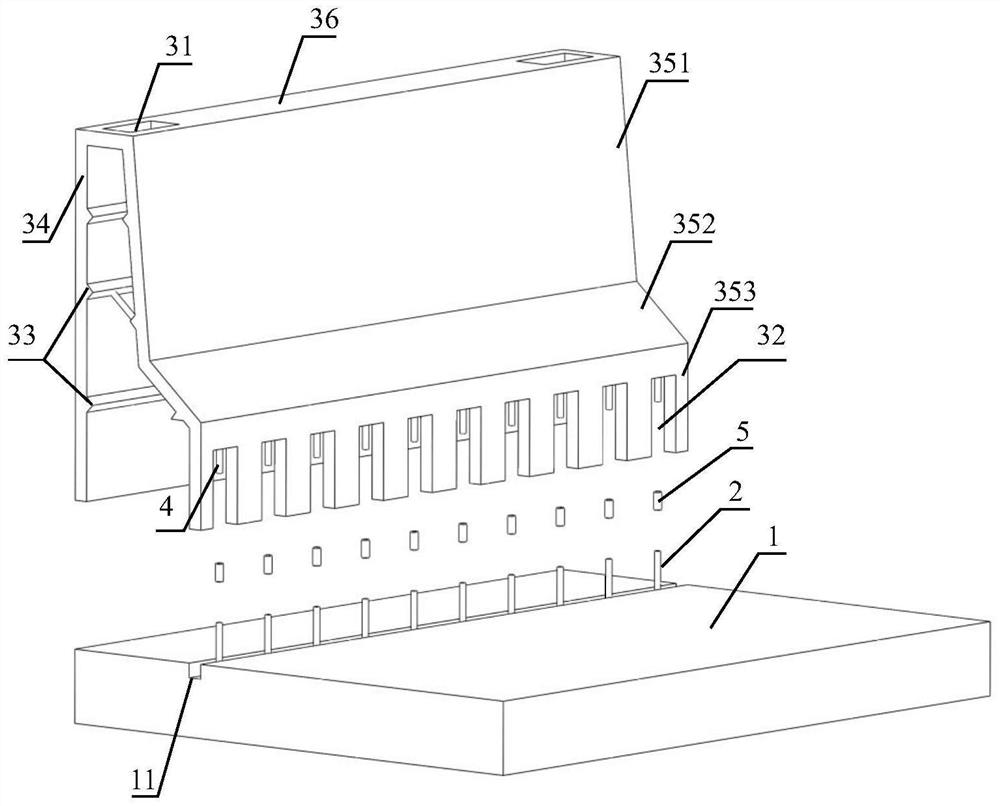

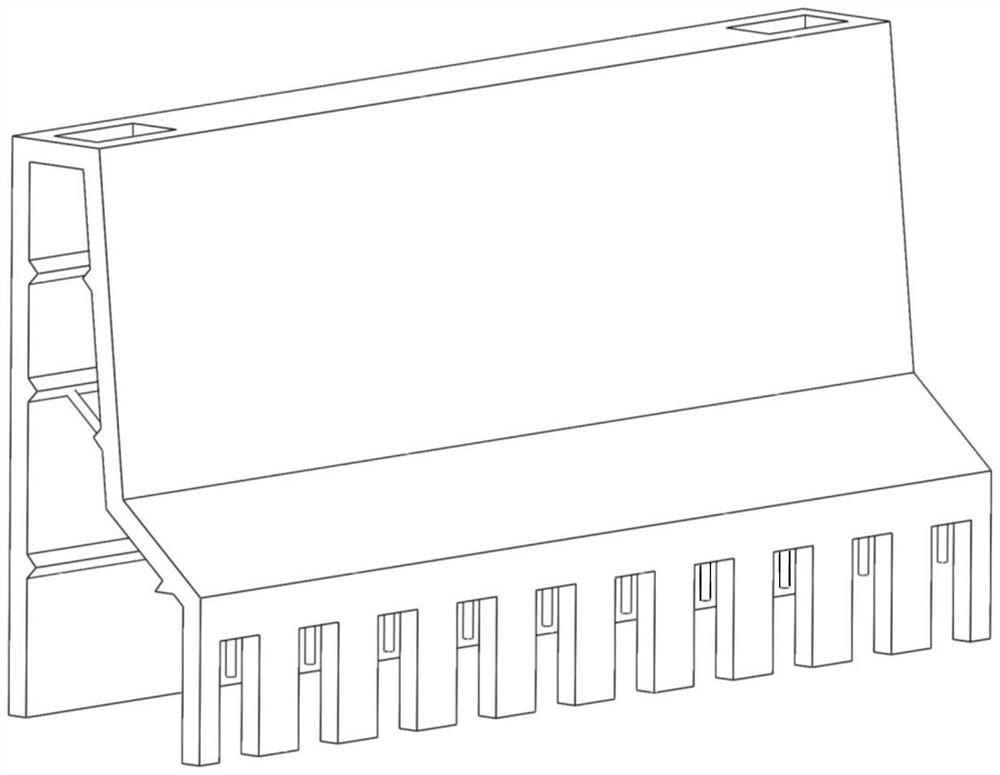

[0049] This example provides a preferred embodiment, a prefabricated UHPC formwork filled with concrete bridge guardrails, such as Figure 1 to Figure 2 As shown, the bridge guardrail includes a prefabricated UHPC formwork 3, several pre-embedded steel bars 4 and at least one grouting hole 31, wherein:

[0050]The above-mentioned UHPC mold shell 3 includes a first shell 34, a second shell 35, and a third shell 36, the first shell 34 is arranged in a vertical direction, and the second shell 35 and the first shell The bodies 34 are arranged opposite to each other, the length of the second casing 35 in the height direction is greater than the length of the first casing 34 in the height direction, and the top surface of the second casing 35 is flush with the top surface of the second casing 35 , the third casing 36 is disposed on the top of the first casing 34 and the second casing 35 . The first shell 34 , the third shell 36 , and the second shell 35 are sequentially connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com