Prefabricated one-shaped thermal insulation wall with lead pipe-coarse sand energy dissipation and shock absorption key and its method

A thermal insulation wall and prefabricated technology, applied to walls, earthquake-proof, protective buildings/shelters, etc., can solve the problems of poor thermal insulation performance, slow construction speed, low seismic energy consumption capacity, etc., to improve thermal insulation effect, The effect of high production efficiency and high level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific implementation cases.

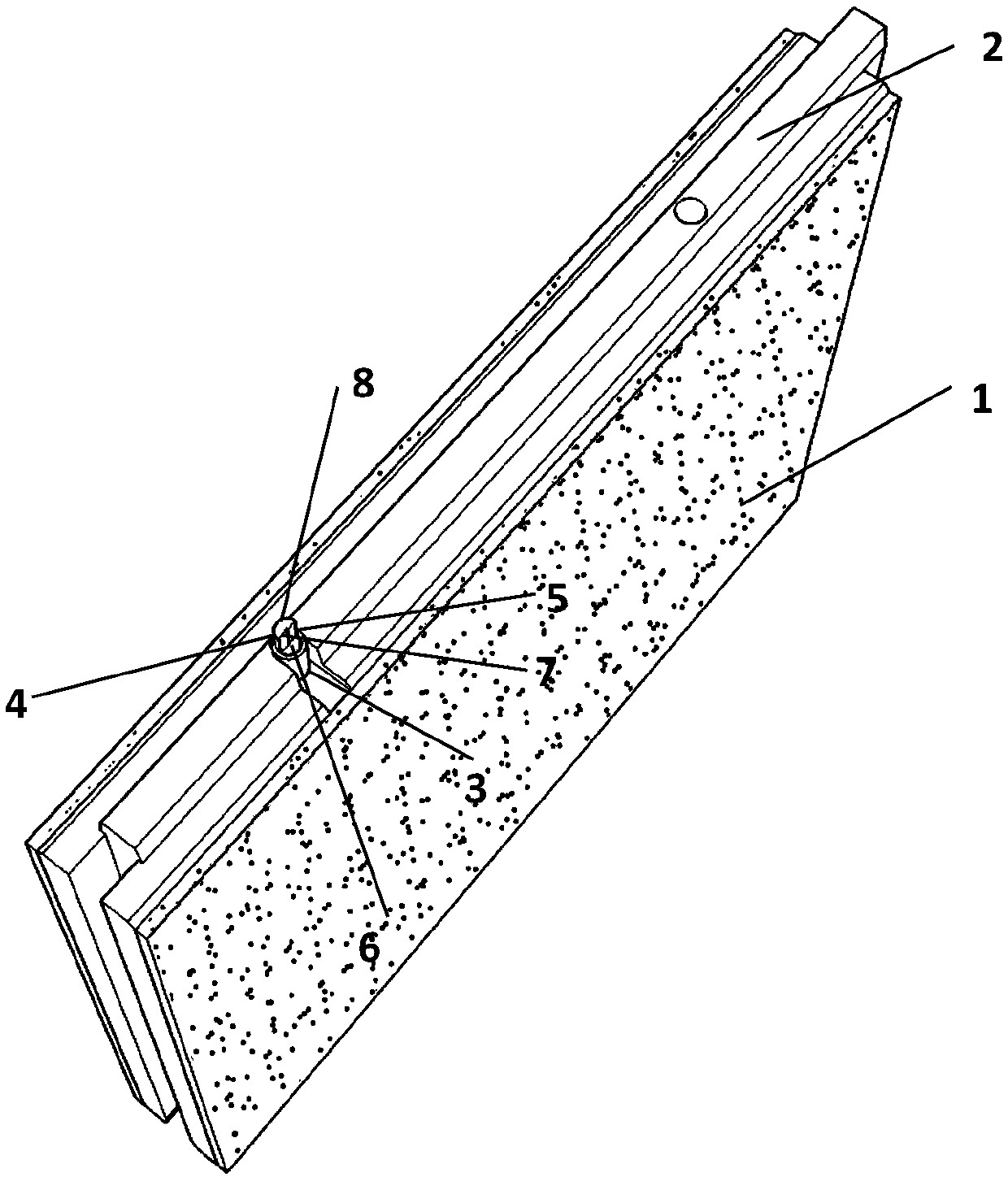

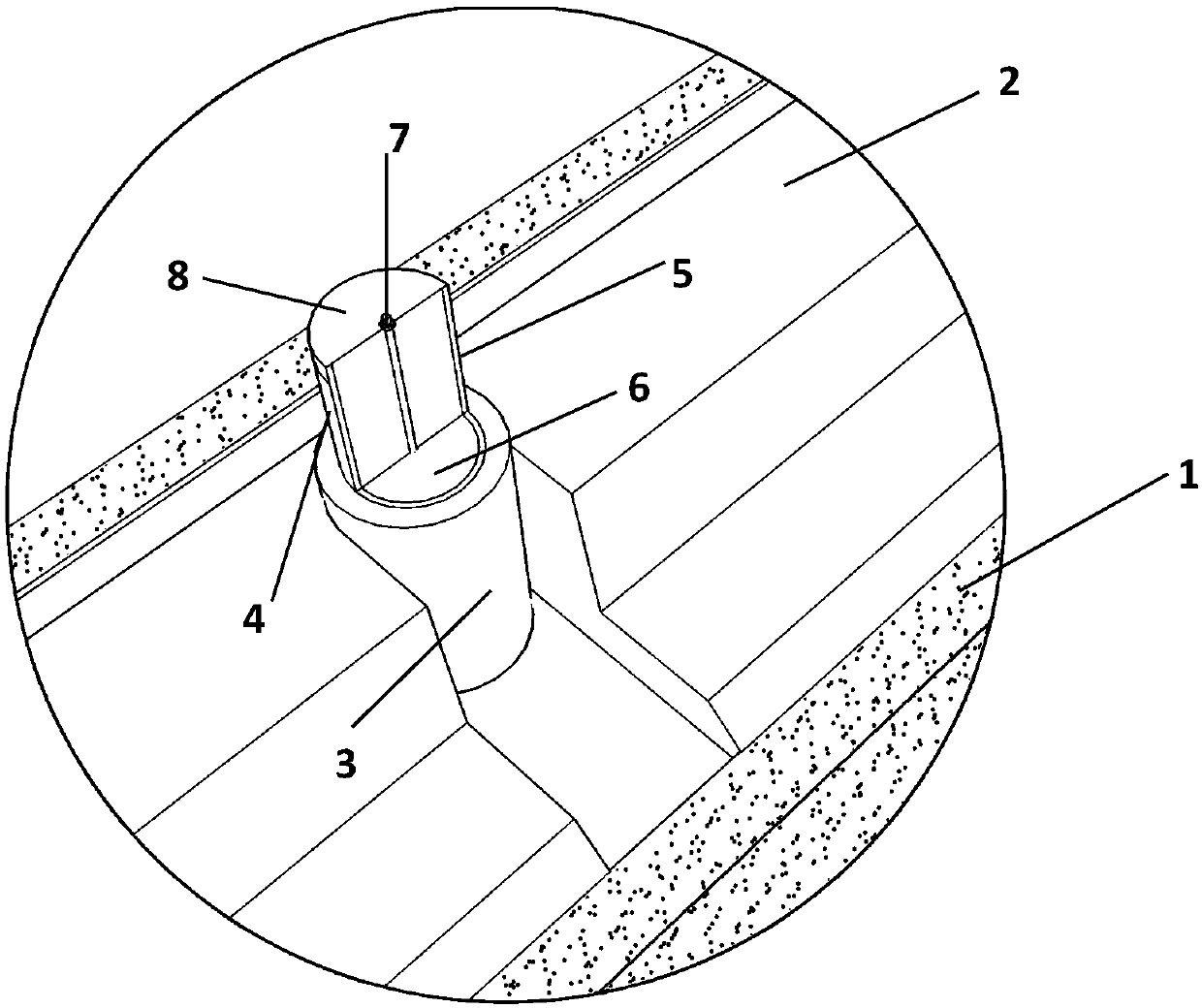

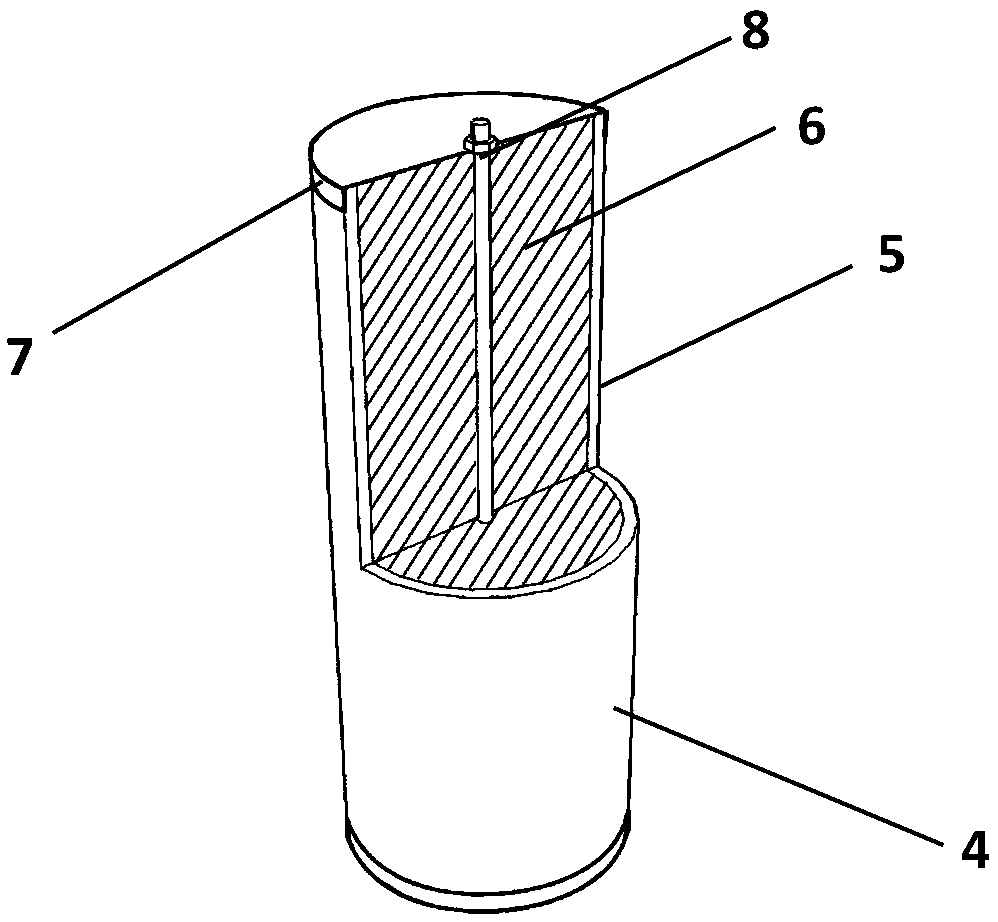

[0038] Such as figure 1 As shown, the assembled in-line thermal insulation wall with lead pipe-coarse sand energy dissipation and shock-absorbing key of the present invention includes calcium silicate boards 1 and foamed cement wall panels on both sides of the in-line thermal insulation wall 2. Winged round pipe fixings 3. Lead pipe-coarse sand energy dissipation key 4. Lead pipe 5, coarse sand 6, galvanized thin steel cover plate 7, bolt 8.

[0039] in particular:

[0040] The calcium silicate board 1 is located on both sides of the foamed cement wallboard 2 as a non-removable template for the foamed cement wallboard 2; the self-tapping screw passes through the calcium silicate board 1 from the outside and is connected to the winged round pipe fixing member 3 The bolt holes on the two wings help the positioning of the calcium silicate board 1 and realize the formation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com