SMC-FRP-concrete combination column

A SMC-FRP-, concrete column technology, applied in the direction of columns, piers, pillars, etc., can solve the problem of unfavorable seismic requirements of FRP-constrained concrete columns, and achieve the effect of increasing three-dimensional compression and improving mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

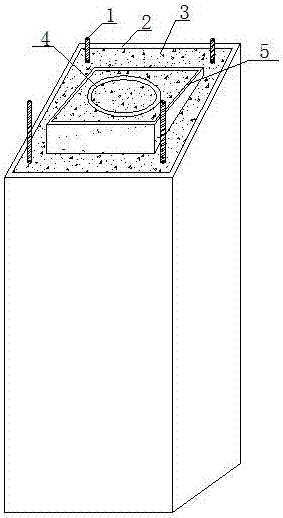

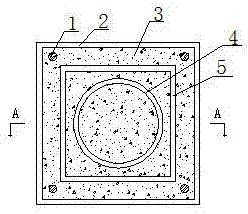

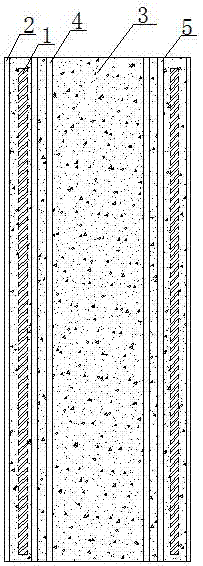

[0016] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0017] The SMC-FRP-concrete composite column of the present invention includes concrete columns, poured FRP bars and FRP plates, and outsourced SMC moulds; the joints of the FRP plates are fixed by sealing corners; the inside of the SMC molds is provided with internal ribs and processed by sticking sand. The SMC tube is placed inside the FRP plate to increase the three-way compression of the composite column. In the production process of SMC-FRP-concrete composite column, firstly, the SMC composite material molding mold is used as the composite column mold; then the bound and fixed FRP cage, the FRP plate whose connection part is fixed by sealing corner, and the SMC casing are placed in the mold in sequence Interior; final pour of concrete. Concrete includes ordinary concrete, recycled concrete, self-compacting concrete, and fiber concrete. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com