Shield tunnel segment caulked joint anti-falling device

A shield tunnel segment and anti-falling technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as train outage accidents, falling off, and short-circuit damage to the catenary, so as to ensure the safety of train operation and facilitate disassembly and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

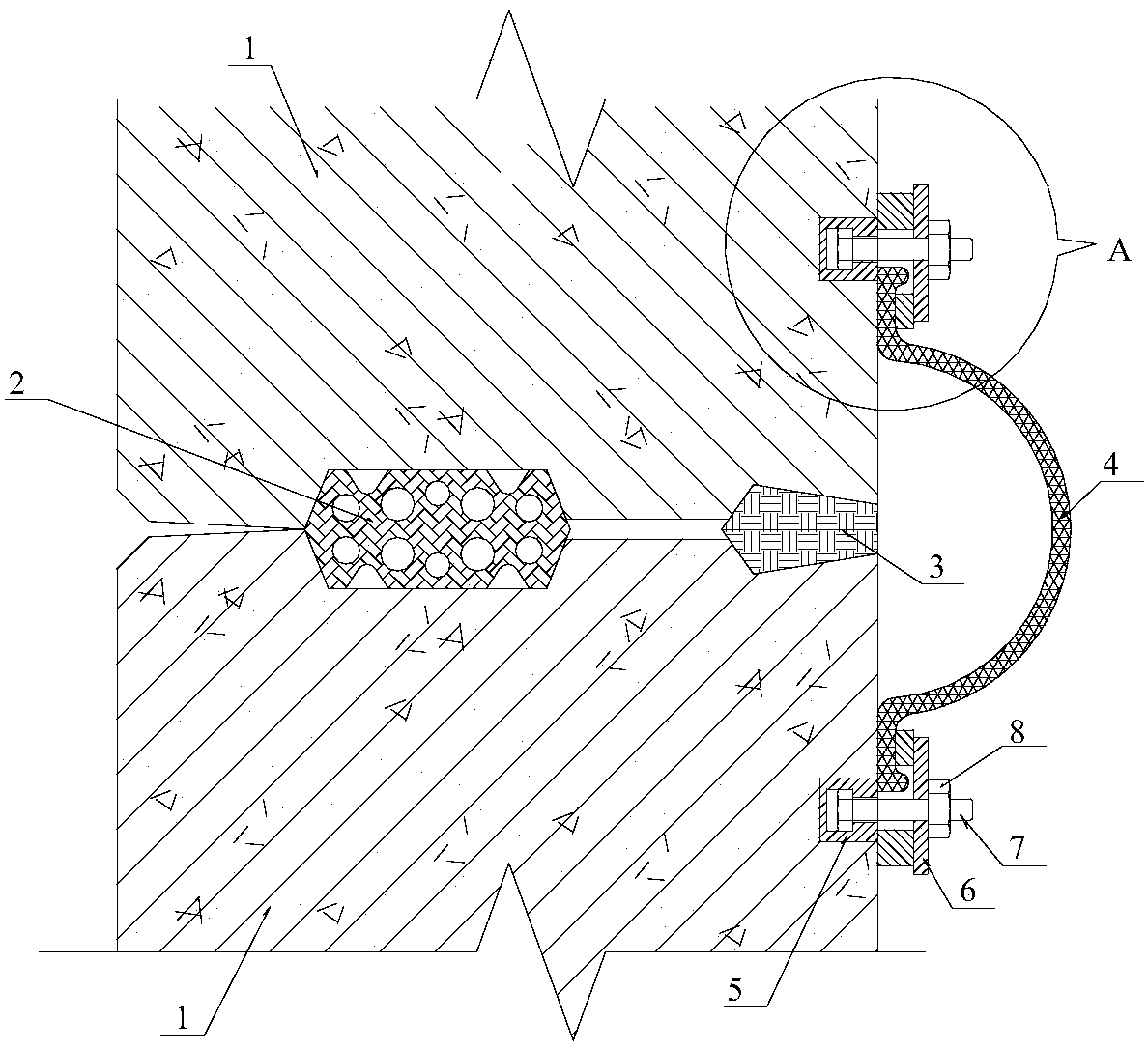

[0020] refer to Figure 1 to Figure 5 , the shield tunnel segment caulking anti-dropping device of the present invention comprises: a chute member 5, embedded in the segment 1 on both sides of the caulking 3, with a T-shaped groove 5a extending along the length direction, the T-shaped groove The opening end of 5a is located on the outer surface of the chute member 5 flush with the inner surface of the segment 1; the bolts 7 are arranged at intervals along the longitudinal direction of the chute member 5, and their heads are located in the T-shaped groove 5a and are vertically constrained by it. The screw section at the tail of the bolt 7 protrudes outward from the T-shaped slot 5a, on which the nut 8 and the pressure plate 6 are set; the arc-shaped rubber belt 4 spans the caulking 3, and its lateral sides pass through the bolt 7, the nut 8, the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com